- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

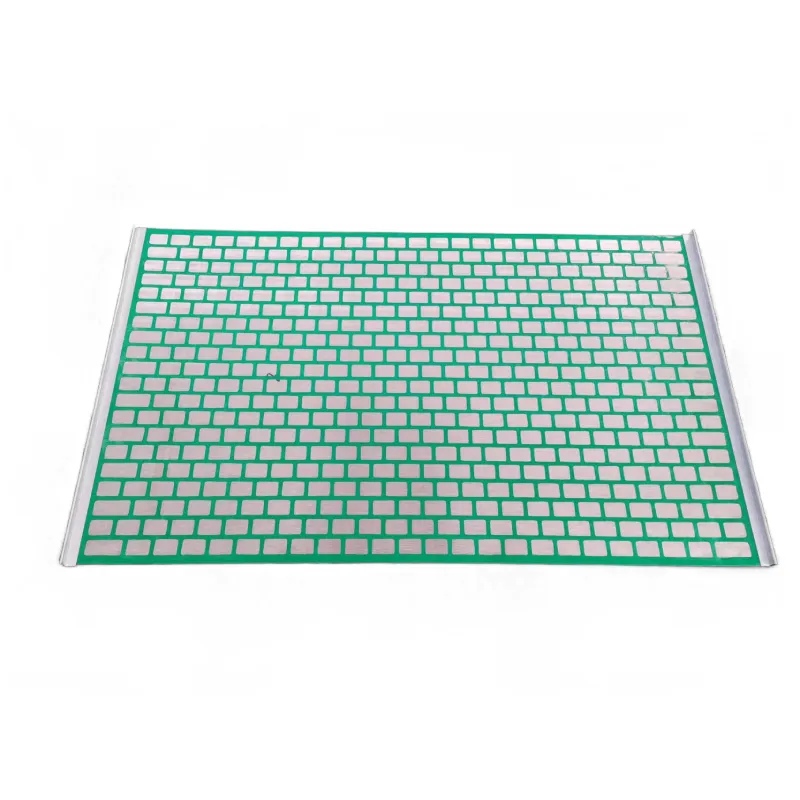

welded steel grating

The Advantages of Welded Steel Grating A Comprehensive Overview

Welded steel grating has emerged as a popular choice across various industries due to its remarkable strength, versatility, and durability. This engineered material has become an integral part of construction, manufacturing, and infrastructure projects, serving multiple applications ranging from flooring and walkways to drainage covers.

One of the primary benefits of welded steel grating is its impressive load-bearing capacity. The welded construction technique enhances the structural integrity of the grating, allowing it to effectively support heavy loads, making it ideal for industrial settings. Industries—such as oil and gas, pulp and paper, automotive, and construction—often require robust flooring solutions that can withstand significant wear and tear, and welded steel grating meets these demands excellently.

Another significant advantage is its slip-resistance feature. Welded steel grating is designed with specific bar spacing and texture that promote good traction and reduce the risk of slips and falls. This is especially crucial in environments where liquids or debris can pose hazards. Safety is a top priority in workplaces, and utilizing welded grating can enhance safety measures effectively.

Welded steel grating is also known for its exceptional longevity. Constructed from carbon steel, stainless steel, or aluminum, it exhibits excellent resistance to corrosive environments when properly treated or coated. Galvanized finishes, for instance, provide a protective layer that enhances rust resistance, making it suitable for outdoor applications or in areas exposed to chemicals. Consequently, businesses can expect minimal maintenance and replacement costs, leading to long-term savings.

welded steel grating

In addition to its strength and durability, welded steel grating is highly customizable. It can be fabricated in various sizes, shapes, and configurations, allowing for tailored solutions that meet specific project requirements. This flexibility means that engineers and designers can easily integrate welded steel grating into their architectural plans without compromising on aesthetics or functionality.

The environmental consideration associated with welded steel grating is also noteworthy. As it is primarily made from recyclable materials, this type of grating contributes to sustainable construction practices. At the end of its life cycle, it can be recycled, reducing the strain on landfills and promoting a circular economy.

Moreover, welded steel grating allows for efficient drainage systems. The open design provides excellent drainage capabilities, preventing water accumulation and reducing the risk of flooding in low-lying areas. This property not only enhances safety but also helps maintain the integrity of adjacent structures and surfaces.

In conclusion, welded steel grating is a versatile, robust, and cost-effective solution for numerous industrial applications. Its exceptional load-bearing capacity, slip resistance, durability, and customization options make it an excellent choice for projects that demand reliability and safety. As industries continue to prioritize sustainability and efficiency, welded steel grating is poised to remain a vital component in modern infrastructure.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025