- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Choosing the Right SWACO Shaker Screens for Optimal Performance and Efficiency

Understanding Swaco Shaker Screens Key to Efficient Drilling Operations

When it comes to drilling operations, particularly in the oil and gas industry, maintaining the integrity of the drilling process is paramount. One of the critical components that facilitate efficient drilling is the shaker screen, specifically those produced by Swaco, a well-known brand in the field of drilling fluids and solid control equipment. In this article, we will explore the importance of Swaco shaker screens, their functions, types, and why they are essential for effective drilling operations.

The Role of Shaker Screens in Drilling

Shaker screens are an essential part of the shale shaker, which is a piece of equipment used to separate drilling fluids from the cuttings produced during the drilling process. As drilling operations progress, the drill bit grinds through various types of rock and sediment, generating rock cuttings that must be removed from the drilling fluid to maintain optimal performance and efficiency.

The primary function of shaker screens is to filter out these cuttings, allowing clean drilling fluid to circulate back into the wellbore. This is critical not only for maintaining the pressure and stability of the well but also for preventing damage to the drill bit, which can result in costly delays and repairs.

Why Choose Swaco Shaker Screens?

Swaco, under the larger umbrella of Halliburton, has a reputation for producing high-quality shaker screens known for their durability and efficiency. There are several reasons why drilling operators prefer Swaco screens

1. Advanced Technology Swaco shaker screens are designed using cutting-edge technology and materials that ensure higher levels of performance and reliability. They are engineered to withstand the harsh conditions often encountered in drilling operations, thereby reducing the need for frequent replacements.

2. Customizable Options One of the standout features of Swaco shaker screens is the variety available to meet different drilling needs. They come in various sizes and mesh configurations, allowing operators to select screens that suit the specific requirements of their drilling environment.

swaco shaker screens

3. Enhanced Performance By effectively separating solids from drilling fluids, Swaco shaker screens contribute to a cleaner and efficient drilling process. This leads to improved drilling rates and reduced wear on equipment, ultimately lowering operational costs.

4. Environmental Considerations With increased focus on environmental responsibility, Swaco screens are designed to help minimize waste. By ensuring efficient fluid recovery, they reduce the volume of drilling fluid and cuttings that need to be handled and disposed of.

Types of Swaco Shaker Screens

Swaco offers a range of shaker screens designed for both linear and circular motion shakers. The primary types include

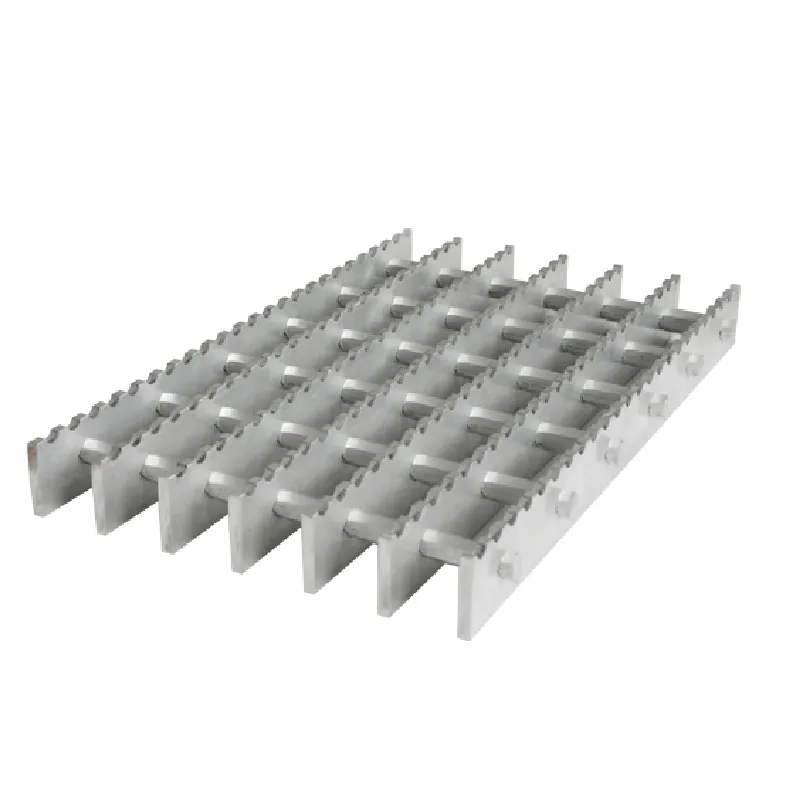

- Steel Frame Screens Known for their durability and strength, these screens are suitable for continuous use in harsh conditions. They provide superior structural integrity, allowing for higher throughput.

- Composite Frame Screens Lighter than steel frame options, these screens are designed to provide excellent performance while reducing the overall weight of the shaker. This can lead to better energy efficiency and easier handling.

- Hybrid Screens Combining the benefits of both steel and composite materials, hybrid screens deliver a balance between performance and weight, making them a popular choice for various drilling applications.

Conclusion

Swaco shaker screens play an indispensable role in the drilling process within the oil and gas sector. Their ability to effectively separate cuttings from drilling fluids ensures that operations run smoothly and efficiently, ultimately saving time and resources. By investing in high-quality shaker screens, drilling operators can enhance their performance, reduce operational costs, and contribute to more environmentally responsible practices. Whether you are drilling on land or offshore, understanding and utilizing Swaco shaker screens can lead to significant improvements in your drilling operations.

-

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025