- ינדוסטריאַל זאָנע, דרום פון אַנפּינג טאַון, הענגשוי, העבעי, טשיינאַ.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  ענגליש

ענגליש  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- ענגליש

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Strong and Safe: Swaged Grating Solutions

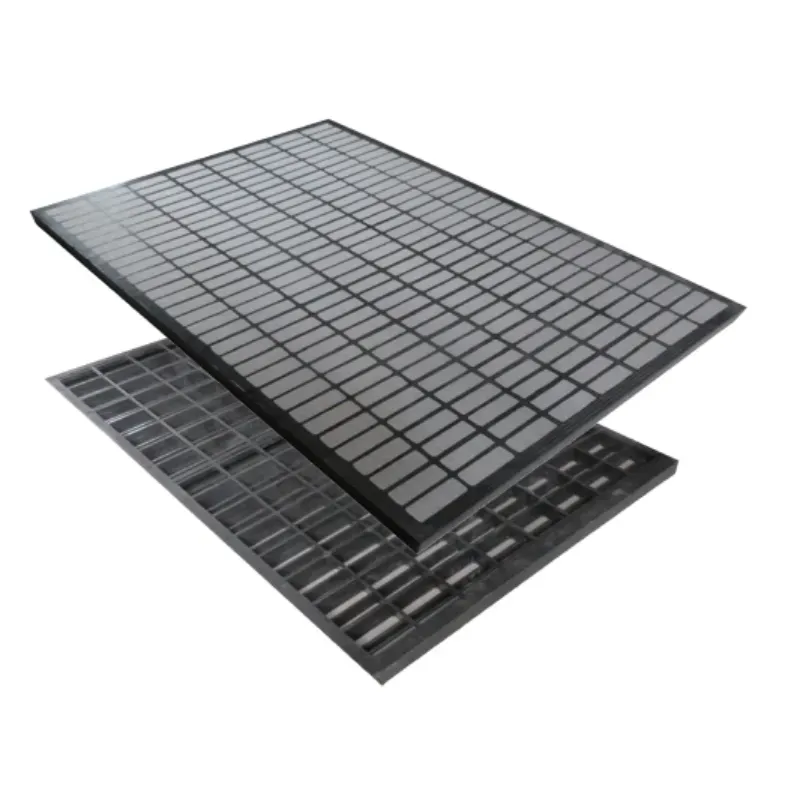

In the energy sector, Press Locked Welded Steel Bar Grating For Oil And Gas Platform Manufacturers is a critical structural element that delivers both strength and safety in demanding offshore conditions. This type of grating is specially engineered for high-load environments, such as oil rigs and drilling platforms, where harsh weather, corrosive seawater, and heavy foot or equipment traffic are routine challenges. The grating is constructed by pressing and welding bearing bars and cross rods together, creating a firm, rigid surface that offers maximum durability. It also features excellent non-slip properties, making it ideal for high-risk zones where worker safety is non-negotiable. These gratings are designed to comply with strict marine and industrial standards, ensuring resistance to wear, corrosion, and deformation. Because of their robustness and long service life, they reduce maintenance costs and downtimes significantly. With customized sizes, shapes, and coatings available, manufacturers catering to oil and gas applications can tailor this grating to meet specific project needs. Whether it's for walkways, platforms, or access floors, this steel grating ensures reliable performance under extreme conditions.

Aluminum Swage Locked Grating for Lightweight Durability

When corrosion resistance and weight reduction are top priorities, aluminum swage locked grating emerges as the go-to solution for architects and engineers. Made from high-quality aluminum, this grating is perfect for environments like marine docks, wastewater plants, and chemical facilities where steel might rust or add unnecessary bulk. The manufacturing process involves inserting cross bars through pre-punched holes in the aluminum bearing bars, which are then permanently locked using a swaging process. This method not only ensures mechanical strength but also prevents loosening over time, making the grating highly reliable for structural applications. The result is a strong yet lightweight product that is easy to install, transport, and maintain. Its resistance to weathering and chemicals, along with its sleek appearance, makes it suitable for both functional and aesthetic applications in architectural designs. Whether it’s used for catwalks, sunshades, or mezzanines, aluminum swage locked grating offers a practical balance between performance and style.

Swaged Grating Offers Strong Bonding and Safety

Ideal for heavy industrial use, swaged grating provides a secure and permanent bond between the bearing bars and cross bars through a process that enhances both durability and safety. The swaging process uses high pressure to deform the cross bars within the slots of the bearing bars, locking them together without welding. This creates a unified structure that can endure vibrations, heavy loads, and impact without coming apart. This type of grating is commonly used in mining, chemical processing, transportation infrastructure, and manufacturing floors where robust, anti-slip surfaces are required. It is also available in various surface finishes such as serrated or plain top surfaces to meet specific safety requirements. Swaged grating is preferred in environments where electrical conductivity and spark resistance are critical, particularly in explosive or flammable atmospheres. Because of its precise engineering and tight tolerance assembly, it minimizes movement and noise, creating a more stable and secure walking or working surface. It's this level of reliability that makes swaged grating a trusted choice for engineers and facility managers worldwide.

Swaged Steel Grating Balances Strength and Cost

A popular choice across multiple industries, swaged steel grating combines the mechanical benefits of steel with the long-lasting durability of swaging. Designed to handle high-load demands, this grating is often installed in areas such as bridges, loading docks, power plants, and factory platforms. The steel provides exceptional strength, while the swaging technique ensures each cross bar is locked into the bearing bar with precision. Compared to traditional welded grating, swaged steel grating offers a tighter bond and less warping over time, especially under thermal or mechanical stress. It is typically made from carbon steel or stainless steel, with options for galvanized coatings to enhance corrosion resistance. Due to its high load-bearing capacity and moderate price point, it is widely used where safety and structural integrity are critical, yet budgets must be carefully managed. The design also facilitates drainage and air circulation, making it ideal for environments prone to spillage or needing ventilation. Swaged steel grating is available in customizable formats, including I-bar configurations, which are lighter and more economical without sacrificing performance.

Plastic Alternative: Why Swage-Locked Steel Grating Leads

While some industries explore alternatives like composites or plastics, swage-locked steel grating remains the preferred choice for heavy-duty applications where structural strength and longevity are essential. Its unique manufacturing method—pressing cross bars into slotted bearing bars and swaging them tightly—results in a solid mechanical bond that won’t loosen under pressure, heat, or movement. This makes it superior to plastic or fiberglass options, especially when exposed to dynamic loads or harsh chemicals. The material options, such as aluminum, carbon steel, and stainless steel, allow for application-specific selection depending on the required corrosion resistance, weight, and strength. The swage-locked steel grating, also known as aluminum grating, features several bar profiles, such as I-bars, which offer lighter weight and cost savings. One of the unique advantages of swaged grating is its structural efficiency: it reduces material use without compromising load-bearing performance. The added benefit of precise bar spacing also contributes to better safety, ventilation, and liquid drainage. While plastic versions may suit certain light-duty settings, they lack the toughness, lifespan, and fire resistance needed for industrial platforms, especially those used in oil and gas operations, construction, and public infrastructure.

Swaged Steel Grating FAQs

What are the main advantages of swaged steel grating?

Swaged steel grating is known for its strength, stability, and long-term performance. It’s resistant to heavy loads, thermal expansion, and harsh environments, making it suitable for industrial use.

How does swaged grating differ from welded grating?

Unlike welded grating, where joints can crack or weaken, swaged grating locks the bars together mechanically using high pressure. This creates a tighter, longer-lasting bond that is less likely to warp or break.

Is aluminum swage locked grating suitable for outdoor use?

Yes, aluminum swage locked grating is corrosion-resistant and lightweight, making it ideal for outdoor settings like marine platforms, bridges, or chemical facilities.

Can swaged steel grating be customized?

Absolutely. Swaged steel grating can be tailored in terms of bar spacing, surface finish (smooth or serrated), and material (stainless steel, carbon steel, or aluminum) to suit specific applications.

Where can I buy quality swage-locked steel grating online?

You can visit our official website to explore product specifications, customization options, and place your order easily. Contact us today to get a quote or request a sample.

If you’re managing construction, oil platform safety, or factory flooring, choosing the right grating matters more than ever. Whether you're sourcing swaged steel grating for an offshore site, selecting lightweight aluminum swage locked grating for a corrosion-prone area, or installing press locked welded steel bar grating for oil and gas platform manufacturers, you're investing in long-term safety and performance. Compared to plastic alternatives, swage-locked steel grating provides durability, load strength, and resistance that modern industrial projects demand. Explore our complete product line online, request a quote, or consult with our technical team to find the best solution for your next project. Don’t compromise—shop with confidence, visit our website today, and get the grating solution that’s engineered to last.

-

Welded Steel Grating: The Strong Foundation for Industrial SafetyנייַעסJul.16,2025

-

Smart Choice For Industrial Safety MeshנייַעסJul.16,2025

-

Press-Locked Steel Grating: The Ultimate in Strength and SafetyנייַעסJul.16,2025

-

Keep Worksites Safer With Practical NettingנייַעסJul.16,2025

-

Helideck Safety Nets: Your First Line of DefenseנייַעסJul.16,2025