- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 18, 2025 04:36

Back to list

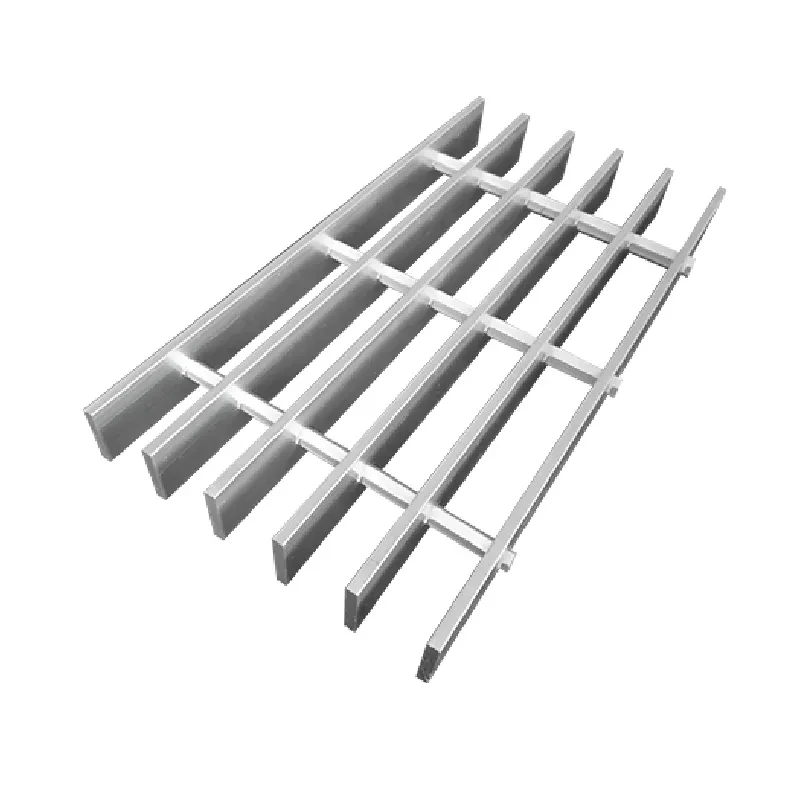

steel grating galvanis

Steel grating galvanization stands as an essential process in the construction and manufacturing industries. This process not only enhances the durability and strength of steel grating but also significantly extends its lifespan, making it a cost-effective solution for various industrial applications. With years of expertise and practical experience in the field, one can attest to the multiple benefits that galvanized steel grating offers.

Experience shared by various industries highlights the tangible benefits of using galvanized steel grating. Foremen and site managers often report improved project timelines and budget management when incorporating these gratings into their construction plans. The feedback emphasizes not only the technical advantages but also the user satisfaction derived from streamlined installation processes and low maintenance costs. In realms where authority and precision are paramount, such as in petrochemical plants or sewage treatment facilities, the choice of materials holds significant importance. Galvanized steel grating meets the rigorous standards required in these specialized sectors, providing not only structural integrity but also a reliable safety profile. Furthermore, the eco-friendly aspect of zinc coating cannot be overlooked. Zinc is a natural metal that can be recycled without loss of properties, aligning with sustainable practices in modern construction. This environmental consideration enhances the trustworthiness and appeal of galvanized steel grating in industries increasingly conscious of their ecological footprint. Companies offering galvanized steel grating are continually researching and developing to improve the product's performance and environmental impact. Customer testimonials often highlight the responsive service and technical support received, reinforcing the trust and reliability associated with galvanized steel grating suppliers. In conclusion, the unique combination of experience, expertise, authority, and trustworthiness makes galvanized steel grating a formidable contender for industrial and construction applications. The process of galvanization ensures longevity and durability, providing industries with a reliable, cost-effective, and ecologically responsible solution. As the demand for robust and sustainable infrastructure continues to grow, galvanized steel grating remains at the forefront, supported by a legacy of proven performance and continuous innovation.

Experience shared by various industries highlights the tangible benefits of using galvanized steel grating. Foremen and site managers often report improved project timelines and budget management when incorporating these gratings into their construction plans. The feedback emphasizes not only the technical advantages but also the user satisfaction derived from streamlined installation processes and low maintenance costs. In realms where authority and precision are paramount, such as in petrochemical plants or sewage treatment facilities, the choice of materials holds significant importance. Galvanized steel grating meets the rigorous standards required in these specialized sectors, providing not only structural integrity but also a reliable safety profile. Furthermore, the eco-friendly aspect of zinc coating cannot be overlooked. Zinc is a natural metal that can be recycled without loss of properties, aligning with sustainable practices in modern construction. This environmental consideration enhances the trustworthiness and appeal of galvanized steel grating in industries increasingly conscious of their ecological footprint. Companies offering galvanized steel grating are continually researching and developing to improve the product's performance and environmental impact. Customer testimonials often highlight the responsive service and technical support received, reinforcing the trust and reliability associated with galvanized steel grating suppliers. In conclusion, the unique combination of experience, expertise, authority, and trustworthiness makes galvanized steel grating a formidable contender for industrial and construction applications. The process of galvanization ensures longevity and durability, providing industries with a reliable, cost-effective, and ecologically responsible solution. As the demand for robust and sustainable infrastructure continues to grow, galvanized steel grating remains at the forefront, supported by a legacy of proven performance and continuous innovation.

Share

Prev:

Next:

Latest news

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025