- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 15, 2025 09:23

Back to list

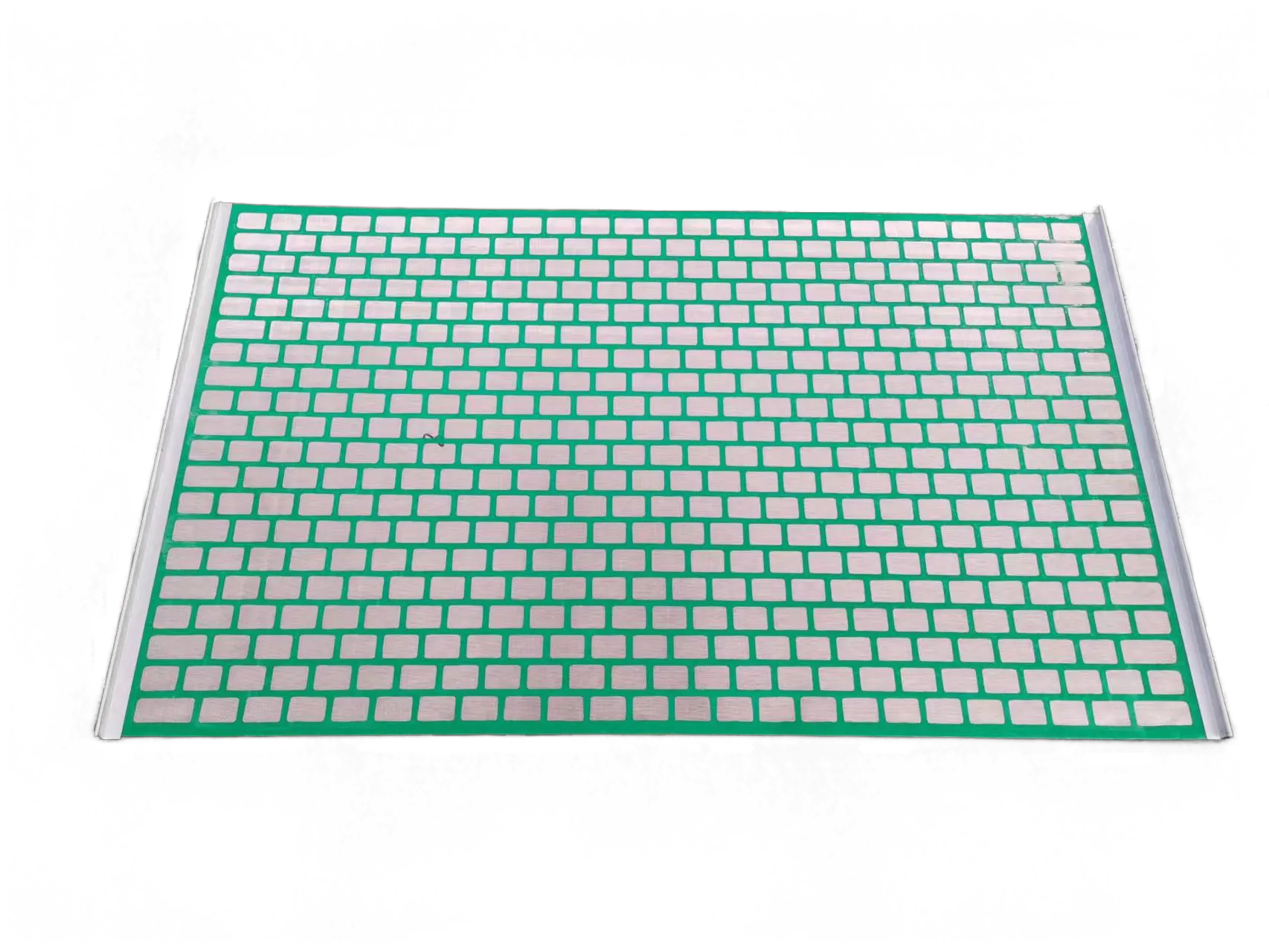

grating treads

Grating treads are a crucial safety feature in numerous industrial and commercial environments. These specially designed, durable platforms not only enhance safety by providing a non-slip surface but also promote efficiency and durability. Understanding the importance of grating treads in terms of materials, industry applications, and proper installation provides invaluable knowledge for businesses aiming to adhere to safety standards and optimize their workspaces.

Real-world experience has consistently shown that the investment in high-quality grating treads leads to reduced long-term costs associated with workplace accidents and injuries, as well as lowered insurance premiums. Companies that have proactively upgraded walkways, staircases, and platforms with the appropriate grating solution report significant improvements in both safety metrics and employee confidence. Additionally, compliance with international safety standards not only minimizes the risk of legal complications but also strengthens the company’s reputation as an industry leader. From an authoritative perspective, adherence to the standards set by organizations such as the Occupational Safety and Health Administration (OSHA) or the European Union safety directives underscores a company’s commitment to workplace safety and quality. Astute business leaders recognize that comprehensive expertise in the deployment of grating treads distinguishes a company as both forward-thinking and trustworthy. To further enhance trustworthiness and encourage informed decision-making, companies should seek out suppliers with established histories of delivering quality products and who provide clear, transparent information on material performance and compliance standards. Collaborating with reputable suppliers who offer extensive product testing, certification, and robust aftersales support fosters an ecosystem of trust and ensures value at every stage of the product lifecycle. In conclusion, the strategic implementation of grating treads represents an indispensable aspect of a company’s infrastructure planning and operational safety strategy. By selecting the appropriate materials, adhering to authoritative guidelines, and engaging with industry experts during installation and maintenance, businesses optimize both the safety and efficiency of their operational environments. Emphasizing these key factors not only fortifies a worksite against potential hazards but also consolidates a company’s standing as an exemplary and committed industry participant.

Real-world experience has consistently shown that the investment in high-quality grating treads leads to reduced long-term costs associated with workplace accidents and injuries, as well as lowered insurance premiums. Companies that have proactively upgraded walkways, staircases, and platforms with the appropriate grating solution report significant improvements in both safety metrics and employee confidence. Additionally, compliance with international safety standards not only minimizes the risk of legal complications but also strengthens the company’s reputation as an industry leader. From an authoritative perspective, adherence to the standards set by organizations such as the Occupational Safety and Health Administration (OSHA) or the European Union safety directives underscores a company’s commitment to workplace safety and quality. Astute business leaders recognize that comprehensive expertise in the deployment of grating treads distinguishes a company as both forward-thinking and trustworthy. To further enhance trustworthiness and encourage informed decision-making, companies should seek out suppliers with established histories of delivering quality products and who provide clear, transparent information on material performance and compliance standards. Collaborating with reputable suppliers who offer extensive product testing, certification, and robust aftersales support fosters an ecosystem of trust and ensures value at every stage of the product lifecycle. In conclusion, the strategic implementation of grating treads represents an indispensable aspect of a company’s infrastructure planning and operational safety strategy. By selecting the appropriate materials, adhering to authoritative guidelines, and engaging with industry experts during installation and maintenance, businesses optimize both the safety and efficiency of their operational environments. Emphasizing these key factors not only fortifies a worksite against potential hazards but also consolidates a company’s standing as an exemplary and committed industry participant.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025