- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 11, 2025 02:13

Back to list

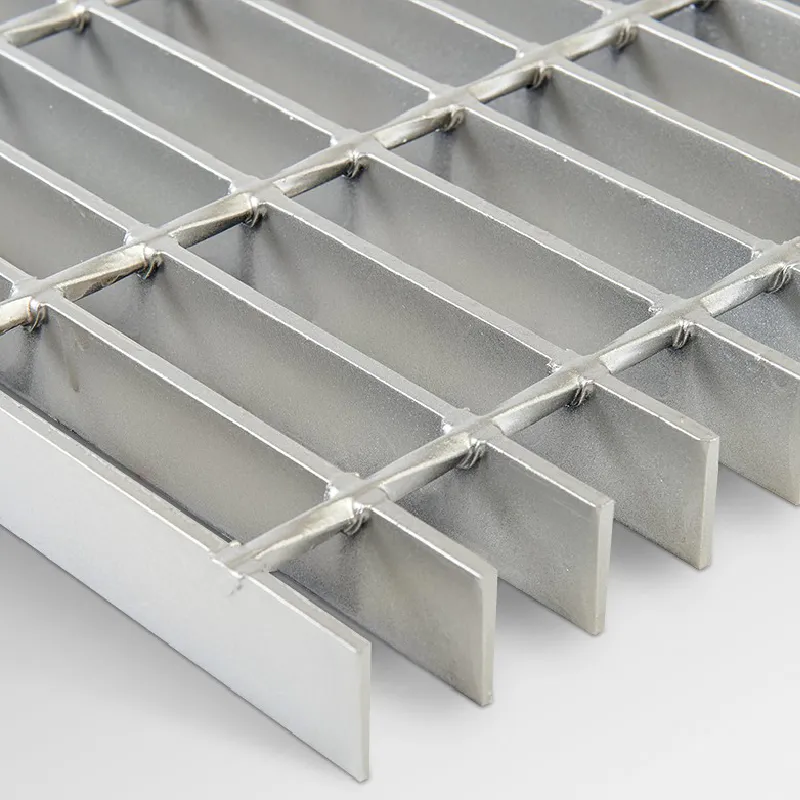

floor steel grating

Floor metal grating stands as a testament to architectural innovation and an essential component in various industrial and commercial applications. Its versatility and durability make it a preferred choice for projects requiring robust flooring solutions. The market offers a plethora of grating options; however, understanding what sets superior quality grating apart requires delving into the design specifications, material composition, and application benefits.

The design of the grating also plays a role in its performance and applicability. Open area design, for example, allows for efficient drainage and ventilation, ensuring that liquids and small debris are quickly dispersed. This feature is especially beneficial in industries dealing with fluids, ensuring workspaces remain clean and dry while maintaining air circulation. Additionally, adequate open spacing complies with various safety codes and regulations set forth by occupational safety entities. Installation efficiency is yet another parameter where quality grating makes a difference. Advanced manufacturing processes have led to grating panels that are easy to install, minimizing labor costs and downtime. Pre-fabricated panels can be tailored to fit specific site dimensions, ensuring a seamless fit that supports efficiency and operational continuity. The testament of quality in floor metal grating lies in certifications and adherence to standards such as those set by the American National Standards Institute (ANSI) or equivalent bodies. Products backed by certifications assure buyers of their reliability and performance, fostering trust and satisfaction. In conclusion, floor metal grating serves a fundamental role across various industries due to its strength, versatility, and adaptability. Understanding the diverse types of materials, surface textures, and installation options allows businesses to select the appropriate grating solution tailored to their needs. By prioritizing quality and complying with industry standards, companies can ensure a safe, efficient, and cost-effective operation that withstands the test of time.

The design of the grating also plays a role in its performance and applicability. Open area design, for example, allows for efficient drainage and ventilation, ensuring that liquids and small debris are quickly dispersed. This feature is especially beneficial in industries dealing with fluids, ensuring workspaces remain clean and dry while maintaining air circulation. Additionally, adequate open spacing complies with various safety codes and regulations set forth by occupational safety entities. Installation efficiency is yet another parameter where quality grating makes a difference. Advanced manufacturing processes have led to grating panels that are easy to install, minimizing labor costs and downtime. Pre-fabricated panels can be tailored to fit specific site dimensions, ensuring a seamless fit that supports efficiency and operational continuity. The testament of quality in floor metal grating lies in certifications and adherence to standards such as those set by the American National Standards Institute (ANSI) or equivalent bodies. Products backed by certifications assure buyers of their reliability and performance, fostering trust and satisfaction. In conclusion, floor metal grating serves a fundamental role across various industries due to its strength, versatility, and adaptability. Understanding the diverse types of materials, surface textures, and installation options allows businesses to select the appropriate grating solution tailored to their needs. By prioritizing quality and complying with industry standards, companies can ensure a safe, efficient, and cost-effective operation that withstands the test of time.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025