- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Exploring the Benefits of Concrete Weight Coating for Pipeline Protection and Stability Solutions

Concrete Weight Coating for Pipeline An Overview

Concrete Weight Coating (CWC) plays a crucial role in the installation and management of pipelines, especially in subsea environments. This process involves applying a layer of concrete to the exterior of the pipeline, providing not only weight for stability but also protection against various environmental factors. As the demand for efficient and safe transportation of oil, gas, and other resources rises, understanding the benefits and applications of concrete weight coating becomes increasingly important.

Purpose and Benefits of Concrete Weight Coating

The primary purpose of concrete weight coating is to provide additional weight to the pipeline, ensuring it remains submerged in water and does not float. This is particularly essential in deep-water applications where buoyancy can pose significant challenges during installation. CWC prevents the pipeline from being displaced by currents or waves, thereby maintaining its intended position on the seabed.

In addition to providing weight, concrete coating also offers several protective benefits. Pipelines are often exposed to harsh environmental conditions, including corrosive seawater, shifting sediments, and biological fouling. The concrete layer acts as a barrier, shielding the steel pipe from corrosion and enhancing its longevity. Moreover, this coating helps protect the pipeline from physical damage caused by fallen debris or accidental anchoring by fishing vessels.

Application Process

The application of concrete weight coating typically occurs in specialized facilities equipped for such processes. First, the steel pipe is cleaned and surface-treated to ensure proper adhesion of the concrete. Following preparation, the concrete mixture is applied using various methods, including rotational coating or pouring. Each method has its advantages, and the choice often depends on the specific requirements of the project.

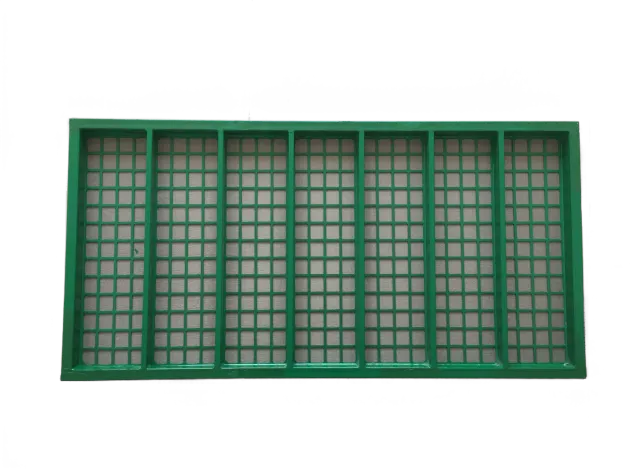

concrete weight coating pipe mesh

After the application of the concrete layer, the pipeline undergoes rigorous quality checks. These inspections assess the integrity of the coating, ensuring it meets the required thickness and bonding standards. Once approved, the coated pipeline is transported to the installation site, ready for deployment.

Environmental Considerations

As global awareness of environmental sustainability increases, the pipeline industry is also evolving. The use of CWC can have ecological impacts, particularly in underwater settings. Therefore, it is critical to ensure that the materials used for concrete coating are environmentally friendly. Many manufacturers are now seeking to employ recycled materials in their concrete mixtures, thus reducing overall environmental footprints.

Moreover, the installation of weight-coated pipelines must adhere to stringent regulations to minimize disturbances to marine ecosystems. Careful planning and execution are vital in ensuring that the pipeline's installation does not adversely affect local wildlife or habitats.

Conclusion

Concrete Weight Coating represents a vital innovation in the field of pipeline technology. By providing both weight and protection, CWC enhances the ability to transport essential resources safely and efficiently. As marine and subsea operations continue to expand, so too does the need for effective solutions like concrete weight coating. The ongoing focus on sustainability and environmental protection will further shape the future of concrete applications in the pipeline industry, ensuring that the balance between industrial progress and ecological responsibility is maintained.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025