- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Innovative Solutions for Enhanced Durability in Concrete Weight Coating Applications

The Importance of Concrete Weight Coating in Pipeline Applications

Concrete weight coating (CWC) is a specialized technique used primarily in the oil and gas industry to ensure the stability and functionality of pipelines. As pipelines are laid on the seabed or through challenging terrains, they require additional weight to resist buoyancy and various environmental forces. This article delves into the significance of concrete weight coating, its application processes, and its benefits in the context of pipeline installation.

What is Concrete Weight Coating?

Concrete weight coating involves applying a layer of concrete around pipelines to increase their weight and protect them from environmental factors. This protective layer serves multiple purposes it provides ballast to counteract buoyancy, shields the pipeline from external pressures, and offers resistance against external corrosion. The concrete used is typically reinforced for increased durability and tailored to withstand various environmental conditions.

Applications of Concrete Weight Coating

CWC is primarily utilized for sub-sea pipelines that transport oil and gas. In offshore environments, pipelines are exposed to strong currents and wave action, necessitating a robust coating to prevent them from being moved or damaged. Additionally, CWC is effective for onshore installations where the soil conditions are unstable or where the pipeline needs to cross uneven terrain.

The application of concrete weight coating begins with cleaning and preparing the pipeline surface. Once ready, a layer of concrete is applied, which can vary in thickness depending on the specific requirements of the project. This is typically done using automated machinery to ensure even application and consistency. After the concrete is cured, it forms a dense and protective shell that provides both weight and resilience.

Advantages of Concrete Weight Coating

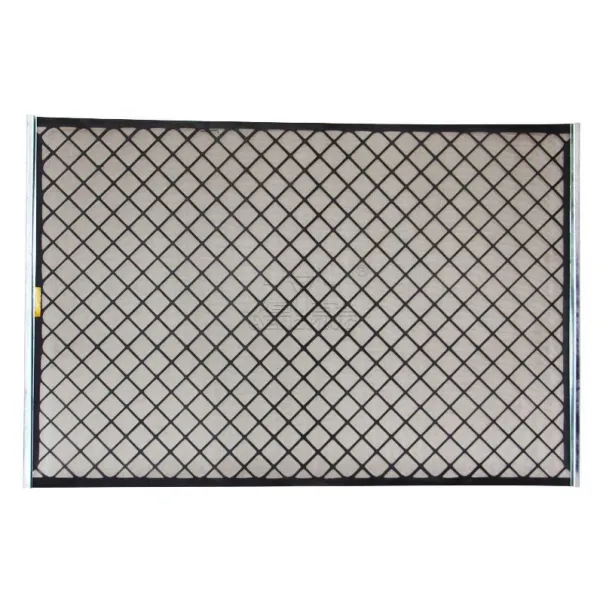

concrete weight coating

1. Buoyancy Control One of the primary advantages of concrete weight coating is its ability to control buoyancy. In deep-water pipelines, floating or shifting is a significant concern. The added weight from the concrete prevents this, keeping pipelines securely in place on the seabed.

2. Protection The concrete layer not only provides weight but also acts as a protective barrier against impacts from marine life, underwater debris, and other external influences. This layer helps prevent corrosion and damage, extending the lifespan of the pipeline significantly.

3. Cost Efficiency By extending the lifespan of pipelines and reducing the need for frequent maintenance or replacements, concrete weight coating can lead to significant cost savings over time. Moreover, CWC can help minimize downtime during operations, contributing to more efficient project timelines.

4. Environmental Compliance Many regions require stringent environmental protection regulations for pipeline installations. Using concrete weight coating can ensure compliance with these regulations, as the added protection reduces the risk of leaks or spills that could arise from damage.

5. Customization Concrete weight coating is highly customizable. Engineers can adjust the thickness and density of the concrete layer based on specific project requirements, soil conditions, and environmental factors. This adaptability ensures that pipelines are safeguarded against localized conditions.

Conclusion

Concrete weight coating is an essential component in the safe and effective installation of pipelines, especially in challenging environments such as offshore and uneven terrains. By providing the necessary weight, protection against external elements, and compliance with environmental regulations, CWC enhances the longevity and reliability of pipeline systems. As the demand for oil and gas continues to grow, the importance of effective solutions like concrete weight coating remains ever crucial, ensuring that infrastructure can withstand the conditions they face in today’s industrial landscape.

-

The Versatility of Steel Walkway GratingNewsAug.07,2025

-

The Benefits of Galvanized Steel Grating for Your ProjectsNewsAug.07,2025

-

Shaker Screens: The Ultimate Solution for Your Drilling NeedsNewsAug.07,2025

-

Perimeter Safety Net: An Essential Solution for Helipad SafetyNewsAug.07,2025

-

Enhance Safety and Efficiency with Steel Walkway GratingNewsAug.07,2025

-

Discover Exceptional Steel Grating for SaleNewsAug.07,2025