- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Th2 . 18, 2025 11:02

Back to list

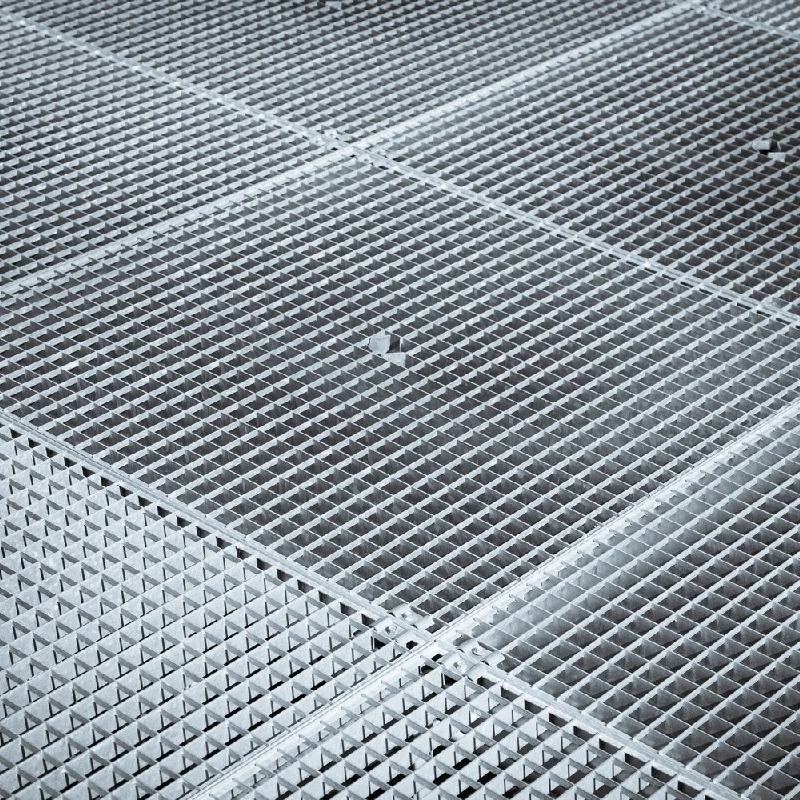

Riveted Grating

Navigating the vast landscape of industrial products can be daunting, especially when it comes to understanding the intricacies of floor grating prices. In the arena of industrial flooring solutions, floor gratings stand out for their durability, safety, and versatility. Grasping the nuances of pricing not only aids in budgeting but also ensures that businesses get the optimum return on investment without compromising on quality or safety.

Supplier selection is another crucial element affecting pricing, where sourcing from reputable manufacturers ensures quality assurance but may impact initial expenditure. Trusted suppliers often adhere to stringent industry standards and provide certifications to validate product quality. Though their products might appear more expensive upfront, they typically deliver long-term savings through durability and reduced maintenance needs. Transport and installation costs further add layers to the overall expense of floor gratings. Transport logistics, especially for bulk orders, require careful planning to minimize costs, while installation demands expertise to guarantee safety and functionality. The complexity of installation varies with grating type, with some requiring precise engineering to fit into existing structures, potentially influencing labor costs. Here, engaging experienced professionals assures not only proper installation but also adherence to safety standards and regulations, vital in sectors like manufacturing, oil and gas, and public infrastructure. Future-proofing your investment is critical, and this involves considering the total lifecycle cost of floor gratings, which encompasses initial purchase, maintenance, and eventual replacement. Opting for higher quality, durable gratings might stretch budgets initially, but it generally results in lower operational costs over the product's lifespan. Regular maintenance, although not the primary concern, should be factored into the overall cost analysis to preserve integrity and functionality, thereby maximizing the grating’s service life. In conclusion, comprehensively understanding floor grating prices involves evaluating several factors material selection, grating type, manufacturing process, supplier credibility, and associated logistical costs. For industry professionals, the key lies in balancing initial investment with long-term benefits, ensuring that cost-efficiency aligns with safety and performance criteria. A well-informed approach not only optimizes expenditure but also enhances operational safety and efficiency, underpinning the critical role floor gratings play in industrial infrastructure. Through strategic planning and expert consultation, businesses can navigate these complexities, securing gratings that meet both budgetary and functional demands.

Supplier selection is another crucial element affecting pricing, where sourcing from reputable manufacturers ensures quality assurance but may impact initial expenditure. Trusted suppliers often adhere to stringent industry standards and provide certifications to validate product quality. Though their products might appear more expensive upfront, they typically deliver long-term savings through durability and reduced maintenance needs. Transport and installation costs further add layers to the overall expense of floor gratings. Transport logistics, especially for bulk orders, require careful planning to minimize costs, while installation demands expertise to guarantee safety and functionality. The complexity of installation varies with grating type, with some requiring precise engineering to fit into existing structures, potentially influencing labor costs. Here, engaging experienced professionals assures not only proper installation but also adherence to safety standards and regulations, vital in sectors like manufacturing, oil and gas, and public infrastructure. Future-proofing your investment is critical, and this involves considering the total lifecycle cost of floor gratings, which encompasses initial purchase, maintenance, and eventual replacement. Opting for higher quality, durable gratings might stretch budgets initially, but it generally results in lower operational costs over the product's lifespan. Regular maintenance, although not the primary concern, should be factored into the overall cost analysis to preserve integrity and functionality, thereby maximizing the grating’s service life. In conclusion, comprehensively understanding floor grating prices involves evaluating several factors material selection, grating type, manufacturing process, supplier credibility, and associated logistical costs. For industry professionals, the key lies in balancing initial investment with long-term benefits, ensuring that cost-efficiency aligns with safety and performance criteria. A well-informed approach not only optimizes expenditure but also enhances operational safety and efficiency, underpinning the critical role floor gratings play in industrial infrastructure. Through strategic planning and expert consultation, businesses can navigate these complexities, securing gratings that meet both budgetary and functional demands.

Share

Next:

Latest news

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025