- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

aluminum grating specifications

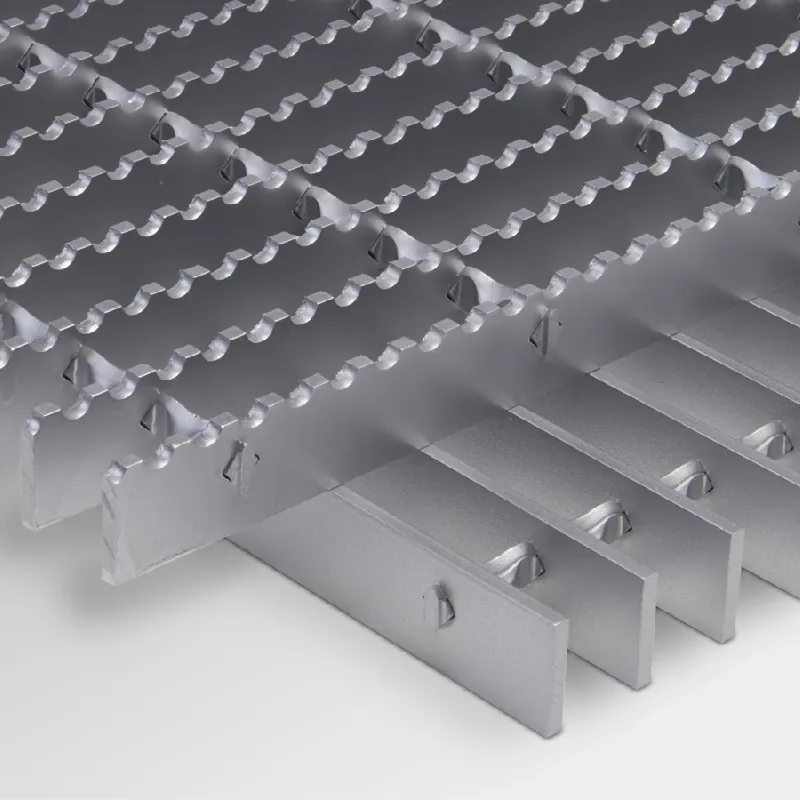

Aluminum Grating Specifications A Comprehensive Overview

Aluminum grating is widely recognized for its durability, versatility, and resistance to corrosion, making it a popular choice in various industrial applications. As an essential component in construction, infrastructure, and safety solutions, understanding aluminum grating specifications is crucial for selecting the right type for specific projects. This article aims to explore the key specifications of aluminum grating, including materials, types, load capacity, and maintenance.

Material Properties

Aluminum grating is primarily made from aluminum alloys, which are selected for their lightweight yet robust characteristics. Common alloys include 6061-T6 and 6063-T5, which offer excellent strength-to-weight ratios, making them suitable for a variety of applications. Moreover, these alloys exhibit good weldability and corrosion resistance, ensuring longevity even in harsh environments. The natural oxide layer that forms on aluminum surfaces provides a protective coating, further enhancing its durability.

Types of Aluminum Grating

There are several types of aluminum grating available, each designed to meet different functional and aesthetic needs

1. Heavy-Duty Grating This type is ideal for applications that require high load capacity, such as walkways and platforms in industrial settings. It typically features thicker bars and closer spacing between them.

2. Light-Duty Grating Used for pedestrian walkways and general-purpose applications, light-duty grating strikes a balance between strength and weight.

3. Architectural Grating These gratings prioritize aesthetics, often featuring custom designs or finishes suitable for commercial or public spaces. They are utilized in applications where visual appeal is essential, such as shopping malls or parks.

4. Bar Grating This is the most common type, consisting of a series of parallel bars with a specific spacing that provides strength and ventilation. Bar grating is often used in flooring, drainage covers, and platforms.

5. Expanded Metal Grating Made from sheets of aluminum that have been cut and stretched, expanded metal grating provides a unique aesthetic while offering good light and air flow. It is often used in fencing and decorative applications.

Load Capacity

aluminum grating specifications

One of the critical specifications for aluminum grating is its load capacity, which is determined by several factors

- Bar Size and Spacing The thickness and width of the bars, as well as the distance between them, significantly influence the overall strength. Thicker bars with closer spacing can bear heavier loads.

- Type of Load Different applications (e.g., dynamic loads from foot traffic versus static loads from equipment) require different considerations in terms of load capacity.

- Support Span The distance between supports plays a crucial role in load distribution. Shorter spans typically lead to higher load capacities.

Manufacturers often provide load tables that specify the maximum load ratings for various configurations of grating, making it easy for engineers and contractors to choose the appropriate type for their projects.

Maintenance

Aluminum grating is relatively low-maintenance, thanks to its corrosion-resistant properties. However, periodic inspections and cleaning are recommended to ensure optimal performance. Regular maintenance includes

- Cleaning Removing debris and contaminants helps maintain traction and aesthetics. In industrial settings, where chemicals may be present, thorough cleaning may be necessary to prevent buildup.

- Inspection Periodic checks for signs of wear, deformation, or damage should be conducted. Early detection can prevent more significant issues and prolong the lifespan of the grating.

- Repair If any damage is identified, timely repairs should be performed to maintain safety standards.

Conclusion

Aluminum grating is an invaluable material across numerous industries, offering a combination of strength, durability, and aesthetic versatility. When selecting aluminum grating for a project, it is essential to consider the specifications, including material properties, types, load capacity, and maintenance requirements. By understanding these factors, engineers and contractors can make informed decisions, ensuring that their projects are both functional and durable. With the right specifications, aluminum grating continues to be a reliable choice for modern construction and industrial applications.

-

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025