- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Exploring the Financial Implications of Steel Grating Pricing Trends and Market Factors

Understanding the Cost of Steel Grating Factors and Considerations

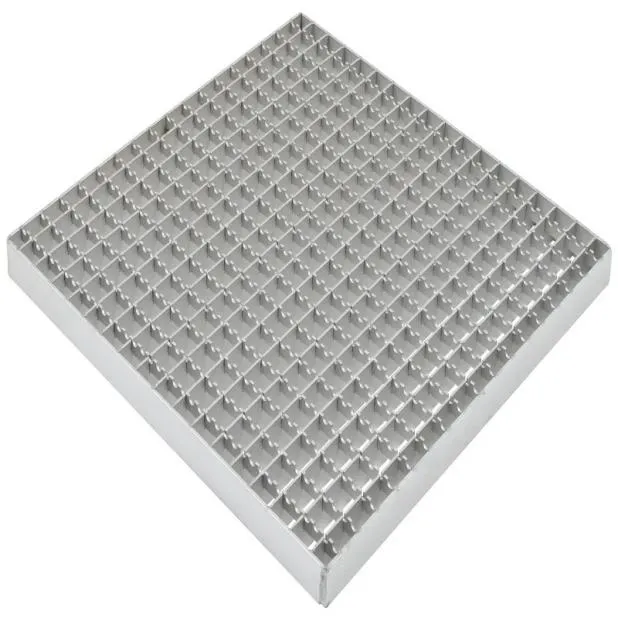

Steel grating is a popular construction material used across many industries, primarily due to its strength, durability, and versatility. Its applications range from flooring and walkways to platforms and stair treads in various environments, including industrial sites, commercial buildings, and even residential areas. When considering a project that requires the use of steel grating, an essential aspect to evaluate is its cost. Understanding the cost of steel grating involves examining several factors that contribute to the overall pricing.

1. Type of Steel Grating

The cost of steel grating can vary significantly depending on the type selected. Common types include welded steel grating, riveted steel grating, and pressed steel grating. Each type has unique manufacturing processes and applications, which can influence cost. Welded grating, for instance, tends to be more robust and is often more expensive due to the extensive welding process that reinforces its structural integrity. On the other hand, pressed grating might be economically priced but may not offer the same strength and stability for heavy-duty applications.

The quality of the steel used in grating production also affects cost. High-quality, low-carbon steel is often more expensive than regular steel due to its superior properties, such as increased resistance to corrosion and enhanced tensile strength. Moreover, some grades of steel can undergo treatments such as galvanization or powder coating, which can add to the cost but provide long-term benefits in terms of durability and reduced maintenance.

3. Size and Customization

cost of steel grating

Steel grating is available in various sizes and configurations, and customization can significantly impact the overall pricing. Standard sizes may be more economical, while custom-cut grating to fit specific project requirements will typically incur additional costs due to the fabrication process. Additionally, the thickness and spacing of the bars in grating can affect its load-bearing capacity and, consequently, its price. It is crucial for buyers to assess their specific needs carefully to balance functionality and cost.

4. Market Fluctuations

The cost of steel grating is also subject to market fluctuations in the price of raw steel. Factors such as supply chain disruptions, international trade policies, and changes in demand can lead to price volatility. For instance, during periods of high demand for construction, the steel prices can rise, impacting the final cost of grating. Tracking market trends and purchasing during favorable conditions can help mitigate these fluctuations.

5. Installation Costs

In addition to the material cost, one must factor in installation costs when budgeting for steel grating. Depending on the complexity of the installation and the project’s location, labor costs can vary. Hiring specialized contractors familiar with steel grating installation may result in higher upfront costs but can ensure the job is done correctly, minimizing long-term issues.

Conclusion

In summary, the cost of steel grating is influenced by various factors, including the type and quality of the material, customization, market conditions, and installation expenses. Project managers and contractors must carefully evaluate these factors when planning their budgets to ensure they select the right type of steel grating that meets both their functional needs and financial constraints. By doing so, they can make informed decisions that will lead to successful project outcomes while optimizing their investments in steel grating.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025