- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Innovative Solutions for Enhancing Safety on Offshore Helidecks with Advanced Netting Systems

Helideck Netting Ensuring Safety in Offshore Operations

In the realm of offshore operations, safety is paramount. Among the myriad of safety measures employed in the industry, helideck netting plays a critical role. Helideck netting refers to the protective netting used around helidecks—designated areas for helicopter landing on offshore installations such as oil rigs and wind farms. This safety feature is designed to provide an additional layer of security, not only safeguarding personnel and equipment but also ensuring the smooth operation of aerial transport in challenging environments.

The Importance of Helideck Netting

Helidecks serve as crucial transit points for crew and supplies in offshore settings. However, the dynamic conditions that characterize marine environments—strong winds, waves, and rough weather—add a layer of complexity to helicopter operations. Helideck netting acts as a barrier that prevents personnel and equipment from accidentally falling overboard during landings and takeoffs. Such incidents can lead to catastrophic consequences, including the loss of life, damage to the helicopter, and significant financial costs to the operating companies.

Furthermore, the netting system aids in the overall operational efficiency of helicopter movements. By creating a defined boundary, it minimizes distractions for pilots and crew, allowing them to concentrate fully on landing and takeoff procedures. The netging also assists in facilitating a controlled environment, ultimately enhancing the safety and reliability of offshore transport.

Design and Specifications

helideck netting

Helideck netting is engineered to withstand the harsh conditions commonly found in offshore environments. Typically made from high-strength, corrosion-resistant materials, the netting is designed to endure exposure to saltwater, high winds, and varying temperatures. The design specifications are subject to strict international regulations to ensure they meet safety standards set by organizations such as the International Marine Contractors Association (IMCA) and the Civil Aviation Authority (CAA).

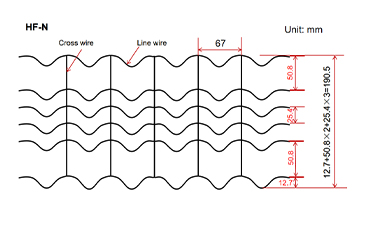

The installation of the netting is a critical aspect of the design process. It must be securely anchored to the helideck to prevent any movement during operations. Additionally, the netting should be of a size and mesh design that effectively contains personnel and equipment while minimizing any impact on helicopter operation space.

Maintenance and Inspection

Like any safety feature, helideck netting requires regular maintenance and inspections. Operators must conduct routine checks to ensure the netting remains intact and free from wear and tear. It is essential to address any signs of damage promptly, including fraying, corrosion, or loosening of anchors. Regular inspections not only adhere to safety regulations but also foster a safe working environment that can significantly reduce the likelihood of accidents.

Conclusion

In conclusion, helideck netting is a vital element in ensuring the safety of offshore operations. By providing a protective barrier, it minimizes the risks associated with helicopter landings and takeoffs in turbulent marine conditions. The robust design, adherence to strict safety standards, and routine maintenance make helideck netting an indispensable feature in modern offshore setups. As the industry continues to evolve towards more efficient and safer practices, the importance of such safety measures cannot be overstated. Enhancing safety protocols, including the implementation of helideck netting, is crucial for protecting personnel and maintaining seamless operations in one of the most challenging work environments on the planet.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025