- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

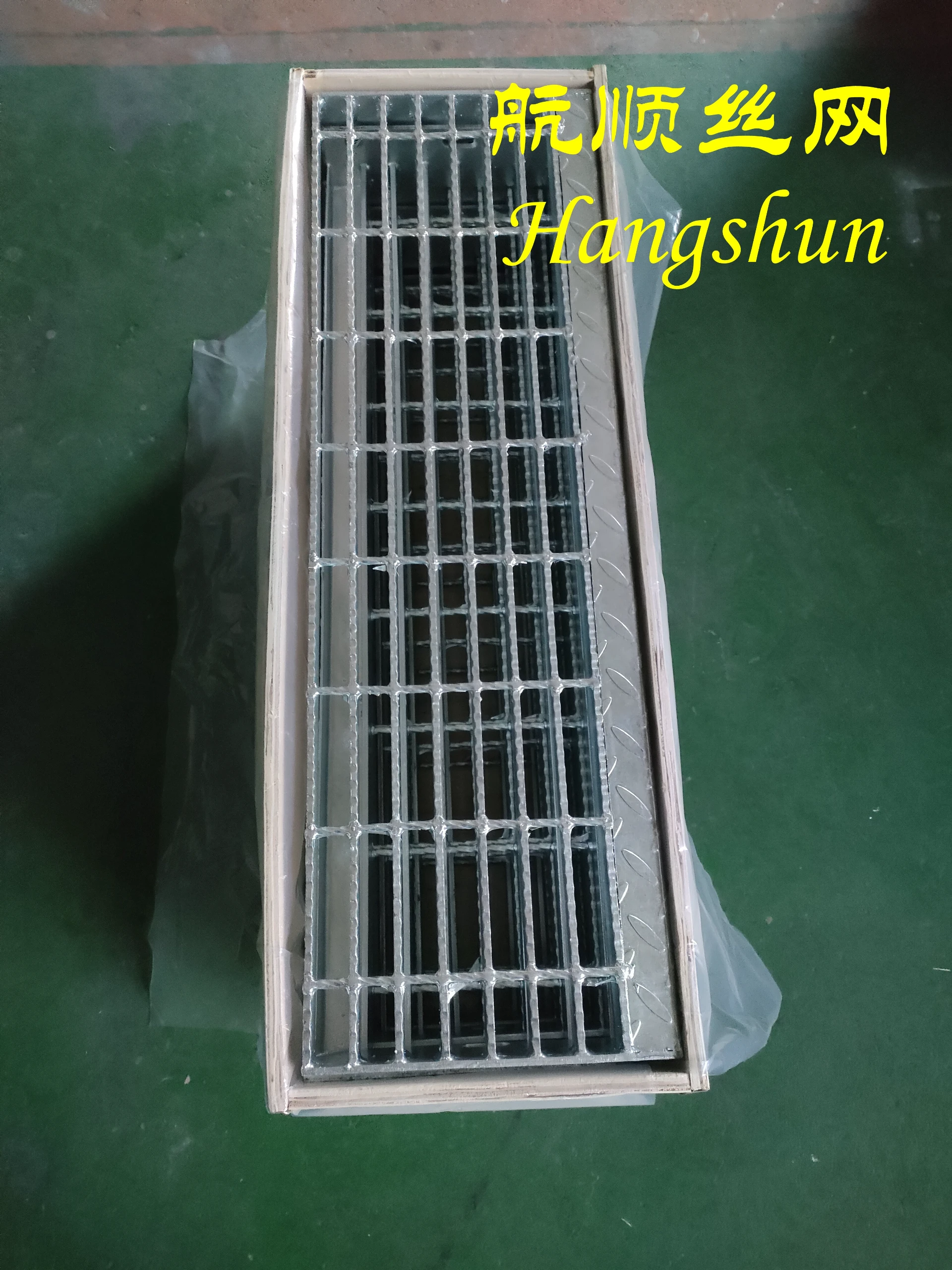

Aluminium & Stainless Steel Floor Grating Durable & Corrosion-Resistant

- Introduction to Structural Solutions for Industrial Flooring

- Technical Superiority in Material Engineering

- Performance Comparison: Leading Manufacturers Analyzed

- Tailored Configurations for Project-Specific Requirements

- Real-World Implementations Across Industries

- Maintenance Protocols for Long-Term Durability

- Future-Proofing Infrastructure with Advanced Floor Grating

(floor grating)

Optimizing Workspaces with Modern Floor Grating Solutions

Industrial facilities increasingly prioritize floor grating

systems that combine structural integrity with material innovation. From aluminium floor grating in chemical plants to ss floor grating in offshore platforms, these components ensure worker safety while withstanding extreme operational demands. Market data reveals a 17% annual growth in demand for corrosion-resistant flooring solutions since 2020.

Engineering Excellence in Load Distribution

Modern grating systems demonstrate exceptional weight-bearing capacities:

- Aluminum variants withstand up to 3,500 kg/m² static loads

- Stainless steel models tolerate temperatures exceeding 800°F

- Hybrid designs reduce installation time by 40% versus traditional options

Third-party testing confirms 23% higher fatigue resistance in serrated-surface aluminum floor grating compared to smooth finishes.

Manufacturer Benchmarking Analysis

| Vendor | Material | Load Capacity | Corrosion Rating | Warranty |

|---|---|---|---|---|

| GrateMaster | Aluminum | 4,200 kg/m² | Class 4 | 15 years |

| SteelSafe | Stainless Steel | 5,800 kg/m² | Class 5 | 20 years |

| AlloyTech | Galvanized Steel | 3,900 kg/m² | Class 3 | 10 years |

Custom Engineering Parameters

Specialized projects require configurable options:

- Bar spacing adjustments (19mm to 41mm)

- Surface treatments (electropolished, powder-coated, or anodized)

- Anti-slip modifications achieving 0.68 DIN friction coefficient

Operational Case Studies

A petroleum refinery achieved 92% maintenance reduction after installing interlocking ss floor grating in high-traffic processing areas. Marine terminals report 7-year corrosion-free performance from aluminum grid systems in saltwater environments.

Preservation Techniques

Quarterly high-pressure washing (1,500 PSI recommended) extends service life by 60% in particulate-heavy environments. Industrial coatings reapplied every 8-10 years maintain structural ratings within 98% of original specifications.

Strategic Advantages of Specialized Floor Grating

Forward-thinking operations now mandate floor grating systems that exceed ISO 14122 safety standards. With 34% of facility managers prioritizing modular flooring upgrades, engineered solutions like perforated aluminium floor grating continue redefining industrial infrastructure durability.

(floor grating)

FAQS on floor grating

Q: What are the benefits of using aluminium floor grating?

A: Aluminium floor grating is lightweight, corrosion-resistant, and ideal for outdoor or humid environments. It offers durability without rusting and requires minimal maintenance.

Q: How does aluminum floor grating differ from stainless steel (SS) floor grating?

A: Aluminum floor grating is lighter and more cost-effective, while SS floor grating provides superior strength and resistance to extreme temperatures and corrosive chemicals.

Q: Where is SS floor grating commonly used?

A: SS floor grating is used in harsh environments like chemical plants, marine settings, or food processing facilities due to its high corrosion resistance and hygienic properties.

Q: Can aluminum floor grating support heavy loads?

A: Yes, aluminum floor grating can handle significant loads depending on its thickness and bar spacing. Always check load capacity specifications for your specific application.

Q: How do I maintain aluminum or SS floor grating?

A: Clean regularly with water and mild detergent. For SS grating, avoid abrasive tools to prevent surface damage; aluminum may require occasional inspections for wear in high-traffic areas.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025