- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Лют . 14, 2025 09:15

Back to list

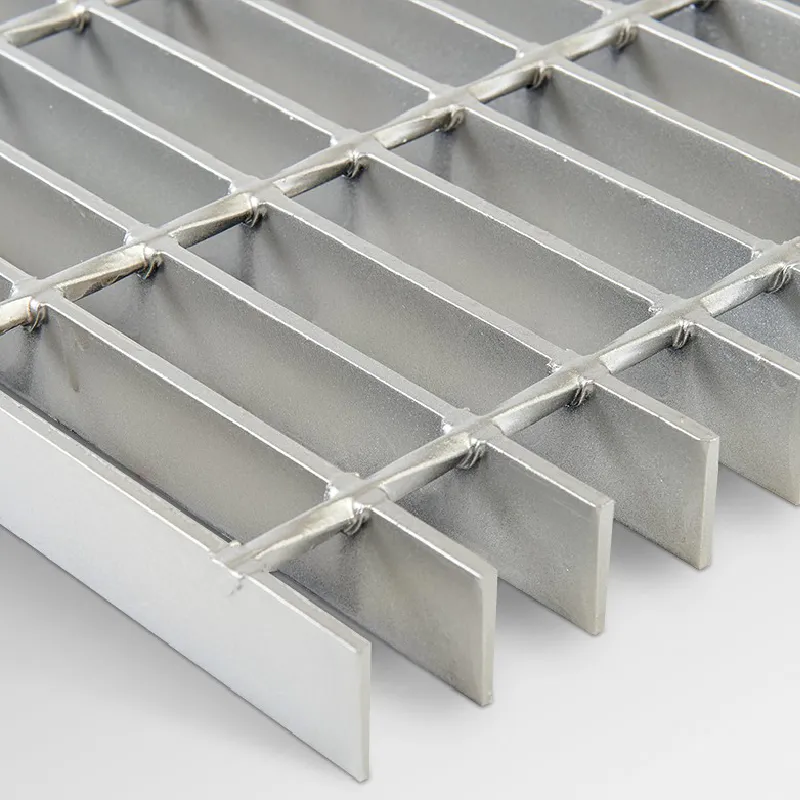

serrated galvanized grating

Serrated galvanized grating is a critical element in industrial flooring and structural applications, boasting a design specifically tailored to ensure maximum safety and durability. As an expert in industrial materials, having explored various applications first-hand, I've witnessed the transformative impact this grating has on enhancing workplace safety and reliability.

Authoritativeness in industrial settings is often gauged by compliance with safety standards and regulations. Serrated galvanized grating is recognized and preferred due to its adherence to the stringent guidelines set out by industry bodies. Engineered to meet specific loading and deflection criteria, it gives businesses peace of mind knowing they're providing their workforce with the safest possible environment. As someone who regularly consults with safety engineers, I've observed the high regard in which this material is held within the professional community. Finally, trustworthiness in product materials is paramount. Organizations need materials that deliver as promised, reducing downtime and maintenance costs. Having interacted with facility managers who rely on serrated galvanized grating, it's evident that its proven track record fosters trust. With lower maintenance demands due to its corrosion-resistant properties, facilities can reallocate resources toward other critical areas. Moreover, its resilience in diverse climates and operational conditions ensures that businesses maintain productivity without the interruption of unforeseen replacements or repairs. In conclusion, serrated galvanized grating is not just a choice but a strategic investment toward a safer, more efficient operational landscape. Its blend of safety, durability, adaptability, and regulatory compliance positions it as an authoritative choice for industries worldwide. Through direct experience and professional engagement, it becomes clear this grating stands as a testament to innovation in industrial design, continually setting the benchmark for safety and reliability.

Authoritativeness in industrial settings is often gauged by compliance with safety standards and regulations. Serrated galvanized grating is recognized and preferred due to its adherence to the stringent guidelines set out by industry bodies. Engineered to meet specific loading and deflection criteria, it gives businesses peace of mind knowing they're providing their workforce with the safest possible environment. As someone who regularly consults with safety engineers, I've observed the high regard in which this material is held within the professional community. Finally, trustworthiness in product materials is paramount. Organizations need materials that deliver as promised, reducing downtime and maintenance costs. Having interacted with facility managers who rely on serrated galvanized grating, it's evident that its proven track record fosters trust. With lower maintenance demands due to its corrosion-resistant properties, facilities can reallocate resources toward other critical areas. Moreover, its resilience in diverse climates and operational conditions ensures that businesses maintain productivity without the interruption of unforeseen replacements or repairs. In conclusion, serrated galvanized grating is not just a choice but a strategic investment toward a safer, more efficient operational landscape. Its blend of safety, durability, adaptability, and regulatory compliance positions it as an authoritative choice for industries worldwide. Through direct experience and professional engagement, it becomes clear this grating stands as a testament to innovation in industrial design, continually setting the benchmark for safety and reliability.

Share

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025