- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

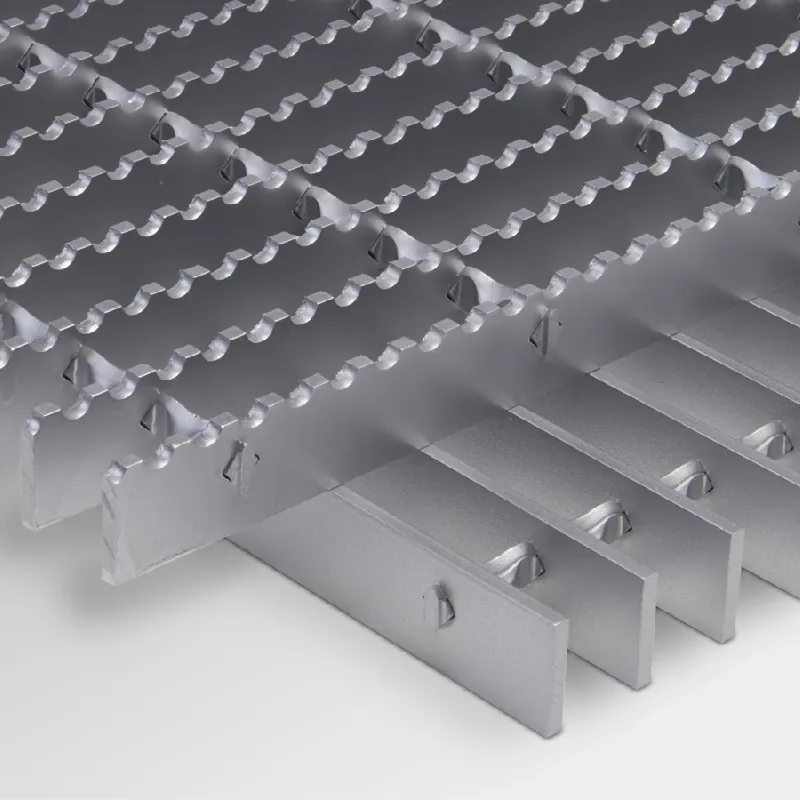

serrated flat bar

Understanding Serrated Flat Bars Applications and Benefits

Serrated flat bars, characterized by their unique surface profiles, are essential components in various industrial applications. These bars are flat metal strips that have serrations or grooves along their surfaces, which enhance their functional properties significantly. Their design provides improved grip, reduced slipping, and increased friction, making them an invaluable resource in diverse sectors.

One of the primary applications of serrated flat bars is in the construction and manufacturing industries. They are often used as stair treads, walkways, and platforms in industrial settings, where safety is paramount. The serrated surface offers better traction, reducing the risk of slipping, especially in environments exposed to moisture, oil, or other slippery substances. This safety feature is crucial in workplaces where heavy machinery operates or where workers frequently move heavy loads.

In addition to safety, serrated flat bars can be used in various load-bearing applications. Their robust design allows them to support substantial weight, making them suitable for structural applications such as railings, frames, and support beams. The ribs created by the serrations can also help to distribute weight more evenly across the surface, enhancing the overall stability of the structure.

serrated flat bar

Serrated flat bars are also common in the agricultural sector, where they are used for making grates and flooring in livestock facilities. The serrated surface prevents animals from slipping, providing a safer environment for livestock while promoting better waste drainage. This feature also contributes to easier maintenance, making it simpler for farmers and facility managers to clean the areas without compromising animal safety.

Another notable use of serrated flat bars is in the creation of effective filtration systems. The grooves in the bars can serve as excellent filters in various applications, including water treatment and air filtration systems. The serrated design helps trap larger particles while allowing smaller ones to pass through, thus enhancing the filtration efficiency. This functional versatility makes serrated flat bars essential in manufacturing equipment where cleanliness and efficiency are critical.

Moreover, serrated flat bars can be customized in terms of size, width, and material, allowing them to meet specific project requirements. Common materials used for these bars include stainless steel, carbon steel, and aluminum, each providing different benefits depending on the application. For instance, stainless steel's corrosion resistance makes it perfect for outdoor uses, while carbon steel offers increased strength for heavy-duty applications.

In conclusion, serrated flat bars are vital components in many industries, providing safety, structural support, and functional versatility. Their unique surface design enhances traction, making them a preferred choice for various applications ranging from construction to agriculture. As industries continue to evolve, the demand for functional and reliable materials like serrated flat bars is likely to grow, highlighting their importance in modern manufacturing and construction practices.

-

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025