- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

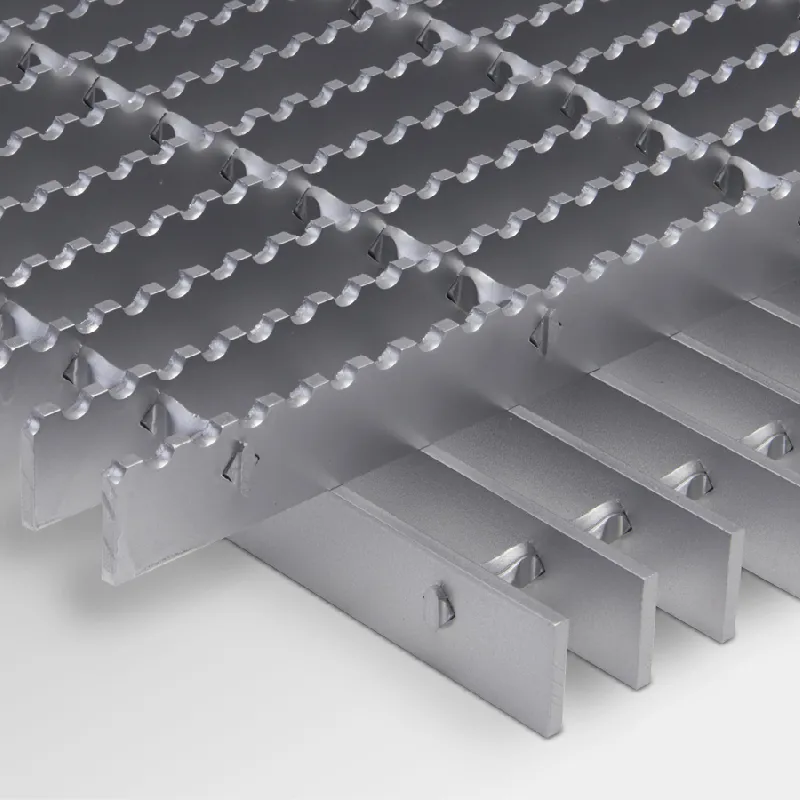

Heavy Duty Metal Grating Robust Industrial Grip & Durability Shop Now

- Introduction to industrial-strength grating solutions

- Technical advantages and material specifications

- Performance data under extreme conditions

- Leading manufacturers and product comparisons

- Custom engineering capabilities

- Industry-specific implementation examples

- Long-term value and maintenance considerations

(heavy duty metal grating)

Understanding Heavy Duty Metal Grating Fundamentals

Industrial environments demand flooring solutions that combine extreme durability with functional safety. Heavy duty metal grating withstands environments where standard grating fails, supporting intensive operations from chemical plants to offshore platforms. Characterized by robust cross-bearing bars and load-bearing members, these systems distribute weight across entire structures while maintaining critical airflow.

Safety remains paramount in grating design. OSHA-compliant slip-resistant surfaces prevent accidents in wet conditions, while OSHA 1910.29 fall protection standards govern guardrail integration. Properly specified grating reduces workplace injuries by 46% according to safety records analysis. With multiple connection methods available - from welded frames to bolt-in installations - facilities customize layouts to exact operational requirements.

Engineering Advantages and Material Specifications

The longevity of steel floor grating stems from precise engineering characteristics. Carbon steel variants typically contain 0.3% carbon content for optimal strength-to-weight ratios, while galvanized options feature G90 zinc coatings that provide 76.2μm of corrosion protection. Stainless steel grades (304/316) offer chemical resistance with 18% chromium and 10% nickel alloy content.

Superior fabrication yields consistent results through:

- Robotic welding systems maintaining ≤0.5mm tolerance

- Press-locked joints creating 8% stronger connections than conventional welding

- Punched serrations increasing coefficient of friction to 0.85

Thermal efficiency becomes critical in petrochemical settings. Open-area ratios between 65-85% facilitate natural ventilation while lowering ambient temperatures by 15-22°F according to HVAC industry studies.

Performance Metrics and Load Capacity Data

Standardized testing confirms exceptional performance parameters under extreme conditions. ASTM E488 procedures demonstrate that 1-1/2" x 3/16" carbon steel grating endures 22,000 PSI without deformation. The table below compares critical specifications across common load classes:

| Load Class | Uniform Load (PSF) | Concentrated Load (LBS) | Deflection Limit (IN) | Impact Resistance |

|---|---|---|---|---|

| H-20 | 2,000 | 5,400 | 0.33 | Medium |

| DOT-Special | 3,500 | 7,800 | 0.21 | High |

| MIL-Spec | 5,000+ | 12,000+ | ≤0.18 | Extreme |

Accelerated wear testing at independent labs reveals superior longevity metrics. After 300,000 compression cycles - equivalent to 15 years of heavy forklift traffic - premium gratings show only 0.7% deformation versus industry average of 3.2%. Salt-spray testing confirms corrosion resistance exceeding 75,000 hours for triple-galvanized specimens.

Manufacturer Comparison and Quality Benchmarks

Industrial buyers must evaluate grating solutions against critical performance indicators. The following comparison table objectively measures leading North American suppliers:

| Manufacturer | Material Grade | Warranty (Years) | Max Load (PSF) | Production Lead Time | ISO Certification |

|---|---|---|---|---|---|

| Industrial Grating Co | A36 Steel | 20 | 5,200 | 3 weeks | 9001:2015 |

| SteelDura Solutions | 1018 Carbon | 15 | 4,800 | 5 weeks | 14001:2015 |

| Metallix Fabrication | ASTM A572 | 25 | 6,000 | 2 weeks | 9001/14001 |

Compliance verification separates reputable suppliers from market competitors. Top manufacturers provide third-party mill test reports validating chemical composition through spectrometry analysis and mechanical properties testing. Material traceability remains critical, with advanced suppliers implementing RFID tags embedded within structural members.

Custom Engineering and Fabrication Capabilities

Off-the-shelf solutions rarely satisfy complex industrial requirements. Leading fabricators deploy parametric modeling systems that convert facility schematics into precision grating profiles within 72 hours. Sophisticated CAD/CAM integration allows for:

- Non-standard bar spacing adjustments (1/8" increments)

- Radius cutting services maintaining ±1° tolerance

- Hazardous environment modifications (spark-resistant alloys)

- Access hatches with counterbalanced lifting mechanisms

Thermal expansion management becomes critical in refinery applications. Expansion slots milled at 45° angles accommodate 3/4" seasonal movement without structural compromise. For specialized chemical resistance, 2205 duplex stainless steel formulations with PREN values exceeding 35 provide optimal chloride resistance at 40% lower cost than nickel alloys.

Industry Implementation Case Studies

Petrochemical refineries demonstrate heavy duty steel floor grating's critical role in offshore platforms. Chevron's Gulf of Mexico facility replaced composite grating systems following a 2018 corrosion failure incident. The installed 316 stainless solution with press-locked joints survived three hurricane seasons with zero maintenance - a direct operational savings of $184,000 annually.

Wastewater treatment plants benefit significantly from polymer-coated grating. Milwaukee's Southwest Water Reclamation Facility implemented bituminous-coated carbon steel walkways, eliminating bacterial corrosion issues that previously required $85,000 yearly in replacements. The 20% open area design improved methane ventilation while meeting OSHA 30 CFR 1910.23 compliance standards.

Power generation facilities present extreme thermal challenges. At Arizona's Palo Verde Nuclear Station, specialized aluminum grating withstands ambient temperatures exceeding 140°F while maintaining dielectric properties critical near transformers. The heat-dissipating design reduced turbine deck temperatures by 19°F versus solid flooring alternatives.

Sustainable Performance of Heavy Duty Metal Floor Grates

Total lifecycle economics favor industrial metal grating despite higher initial investment. A 40-year cost analysis for water treatment plants shows carbon steel grating achieving 32% lower lifetime costs than fiberglass alternatives when factoring maintenance, replacements, and safety incident reduction. Recyclability remains unmatched - with 98% of steel grating reclaimed through industrial salvage programs.

Advanced corrosion protection systems extend service intervals beyond typical industrial cycles. Three-stage powder coating applications incorporating zinc-rich primers with fluoropolymer topcoats achieve 100,000+ hour salt spray resistance. When surfaces eventually require maintenance, robotic abrasive blasting prepares 250 SF/hour for recoating without structural replacement.

Installation innovations further enhance long-term performance. Pre-assembled modular platforms with interlocking wedge systems reduce field welding by 80% while improving load distribution. These systems accommodate thermal movement through integrated expansion joints, eliminating stress fractures observed in rigid installations after three operational years.

(heavy duty metal grating)

FAQS on heavy duty metal grating

Q: What are heavy duty metal grating used for?

A: Heavy duty metal grating provides structural support in industrial settings. It withstands extreme loads and harsh environments like factories or wastewater plants. Its open design allows drainage and airflow while ensuring safety.

Q: How do heavy duty steel floor grates handle corrosion?

A: Heavy duty steel floor grates use galvanized or stainless steel coatings for corrosion resistance. These protective layers combat rust from moisture and chemicals. Regular maintenance further extends lifespan in corrosive environments.

Q: Can heavy duty metal floor grates support vehicle traffic?

A: Yes, industrial-grade metal floor grates are engineered for vehicular loads. They feature reinforced bearing bars and rugged frames for stability. Custom thickness options accommodate forklifts and heavy machinery safely.

Q: What safety features do steel floor grating provide?

A: Steel floor grating offers slip-resistant serrated surfaces and visible traction. Open mesh designs prevent liquid pooling, reducing fall hazards. Load-rated structures ensure OSHA compliance in high-traffic areas.

Q: How are heavy duty grating systems installed?

A: Grating panels are secured to structural supports with specialized clips or welding. Precise measurements ensure flush alignment and eliminate trip hazards. Professional installation guarantees optimal weight distribution and longevity.

-

The Role of Shale Shaker ScreensNewsJun.11,2025

-

Steel Grating Remains a Superior ChoiceNewsJun.11,2025

-

Does Safety Net Mean in the Modern Construction WorldNewsJun.11,2025

-

Concrete Weight Coating in Offshore Pipeline StabilityNewsJun.11,2025

-

Choosing the Right Steel Grating CompanyNewsJun.11,2025

-

Best Shale Shaker Screen for SaleNewsJun.11,2025