- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Лют . 12, 2025 17:09

Back to list

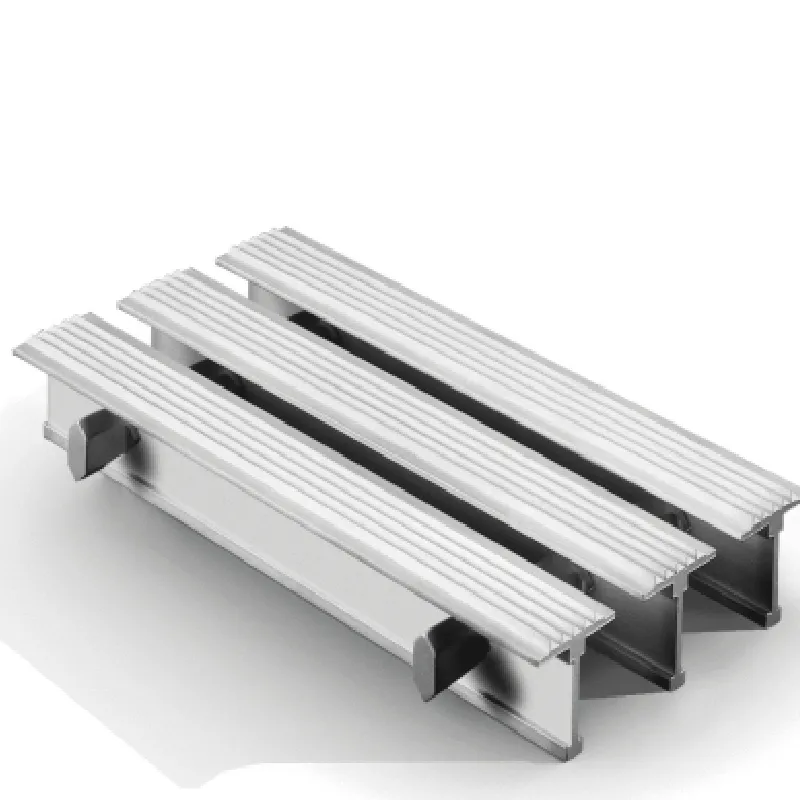

Steel Grating

In the realm of construction and infrastructure development, material selection often dictates the longevity and durability of a project. One material that has proven itself indispensable over time is galvanized iron, particularly in the form of grating. Known for its robustness and resistance to corrosion, grating made of galvanized iron is a preferred choice for many applications.

Moreover, the use of galvanized iron grating contributes to environmental sustainability. The longevity and durability of galvanized products reduce the need for frequent replacements, thereby minimizing resource consumption and waste generation. Additionally, at the end of its long service life, galvanized steel can be fully recycled, maintaining its integrity through repeated cycles of reuse. From an authoritative standpoint, industries and sectors across the globe endorse the deployment of galvanized iron grating. Its widespread acceptance is a testament to its unparalleled performance and durability. Industry leaders and experts consistently advocate for its use, further solidifying its status as an essential component in both existing and new infrastructure projects. Real-world experience echoes these benefits. Consider the case of a coastal oil refinery that needed to replace its walkways. The management chose galvanized iron grating due to its corrosion-resistant properties and load-bearing capacity. Over a five-year period, the refinery reported zero incidents of corrosion or structural failure. The durability and reliability of the grating allowed for uninterrupted operations, which in turn led to increased productivity and fewer maintenance shutdowns. This real-life testimony reinforces the material’s credibility and effectiveness in industrial applications. In conclusion, galvanized iron grating stands as a pillar of strength and reliability in construction materials. Its amalgamation of strength, durability, safety, compliance with international standards, and environmental sustainability make it a formidable choice for a myriad of applications. By harnessing the innate qualities of galvanized iron, professionals across various sectors can ensure that their projects are not only successful but also resilient in the face of environmental and operational challenges.

Moreover, the use of galvanized iron grating contributes to environmental sustainability. The longevity and durability of galvanized products reduce the need for frequent replacements, thereby minimizing resource consumption and waste generation. Additionally, at the end of its long service life, galvanized steel can be fully recycled, maintaining its integrity through repeated cycles of reuse. From an authoritative standpoint, industries and sectors across the globe endorse the deployment of galvanized iron grating. Its widespread acceptance is a testament to its unparalleled performance and durability. Industry leaders and experts consistently advocate for its use, further solidifying its status as an essential component in both existing and new infrastructure projects. Real-world experience echoes these benefits. Consider the case of a coastal oil refinery that needed to replace its walkways. The management chose galvanized iron grating due to its corrosion-resistant properties and load-bearing capacity. Over a five-year period, the refinery reported zero incidents of corrosion or structural failure. The durability and reliability of the grating allowed for uninterrupted operations, which in turn led to increased productivity and fewer maintenance shutdowns. This real-life testimony reinforces the material’s credibility and effectiveness in industrial applications. In conclusion, galvanized iron grating stands as a pillar of strength and reliability in construction materials. Its amalgamation of strength, durability, safety, compliance with international standards, and environmental sustainability make it a formidable choice for a myriad of applications. By harnessing the innate qualities of galvanized iron, professionals across various sectors can ensure that their projects are not only successful but also resilient in the face of environmental and operational challenges.

Share

Prev:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025