- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

يانۋار . 13, 2025 17:13

Back to list

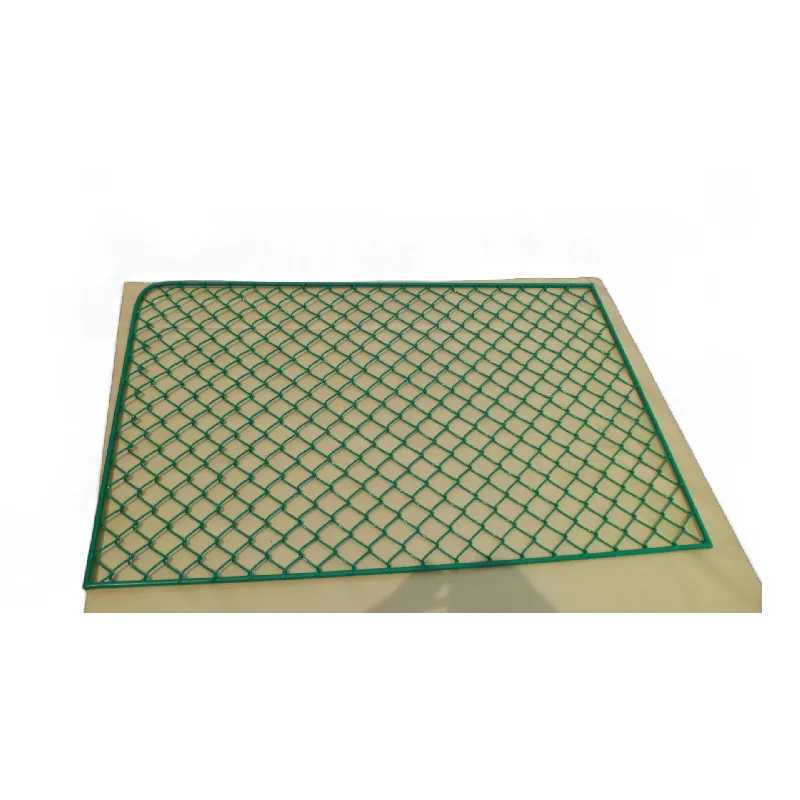

Welded Steel Grating

Welded bar grating stands as a fundamental element in industries requiring durable and robust flooring solutions. This high-strength grid construction, characterized by its welded cross bars and bearing bars, serves an array of applications from industrial flooring systems to safety platforms. At the core of its design is the creation of a strong, unyielding surface that facilitates both foot traffic and industrial operations with minimal maintenance costs.

Trustworthiness in using welded bar grating is established through its compliance with stringent industry standards. Most extensive grating manufacturers conform to ISO 9001 or comparable certifications, ensuring products meet or exceed quality and safety benchmarks. Additionally, ongoing technological advancements have given rise to lighter, more efficient welding techniques that not only preserve structural integrity but reduce the overall weight, facilitating easier installation and reduced labor costs. Professionals in the field recommend routine inspections and maintenance to ensure longevity and safety, even though welded bar gratings require minimal upkeep. Periodic checks can identify potential issues such as wear or corrosion, especially in high traffic or adverse environments, which can then be addressed promptly to prevent any compromise to safety or function. In conclusion, welded bar grating is a pivotal element in modern industrial applications, promising durability, strength, and cost-effectiveness. Its relevance remains unmatched in environments demanding high performance and reliability. When engineered and installed correctly, this robust solution is not only a backbone to industrial flooring applications but a long-term investment toward operational safety and efficiency.

Trustworthiness in using welded bar grating is established through its compliance with stringent industry standards. Most extensive grating manufacturers conform to ISO 9001 or comparable certifications, ensuring products meet or exceed quality and safety benchmarks. Additionally, ongoing technological advancements have given rise to lighter, more efficient welding techniques that not only preserve structural integrity but reduce the overall weight, facilitating easier installation and reduced labor costs. Professionals in the field recommend routine inspections and maintenance to ensure longevity and safety, even though welded bar gratings require minimal upkeep. Periodic checks can identify potential issues such as wear or corrosion, especially in high traffic or adverse environments, which can then be addressed promptly to prevent any compromise to safety or function. In conclusion, welded bar grating is a pivotal element in modern industrial applications, promising durability, strength, and cost-effectiveness. Its relevance remains unmatched in environments demanding high performance and reliability. When engineered and installed correctly, this robust solution is not only a backbone to industrial flooring applications but a long-term investment toward operational safety and efficiency.

Share

Next:

Latest news

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025