- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

يانۋار . 14, 2025 09:35

Back to list

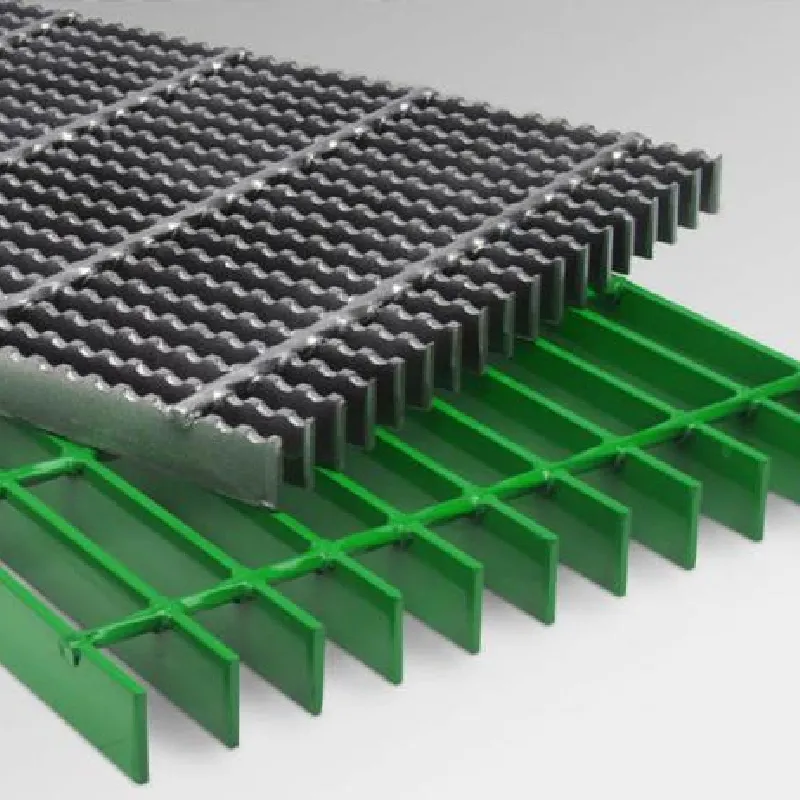

steel walkway grating

Riveted grating stands as a robust option in the realm of flooring and structural engineering, offering both durability and versatility that meet the demands of various industries. Known for its high strength and reliability, riveted grating is constructed by assembling crimp bar and back bar components which are permanently joined together with rivets. This unique construction technique provides superior load-bearing capabilities, making it an ideal choice for heavy-duty applications.

Given the technical nature of riveted grating, those involved in its selection and installation must possess specialized knowledge. Choosing the correct size and spacing of the grating bars is crucial, impacting both the safety and functionality of the final installation. The expertise required to match the grating’s specifications to the project’s unique requirements underscores the importance of experienced engineering oversight. Additionally, installation demands a meticulous approach to ensure each component is correctly aligned and fastened, thereby preserving the structural integrity and longevity of the grating system. The authoritative voice in this domain relies heavily on hands-on experience. Installation teams with a proven track record in handling riveted grating bring invaluable insights that often preclude costly errors. Routine evaluations and maintenance checks guided by industry best practices further lend trust and assurance in the durability of installations utilizing riveted grating. Each inspection offers an opportunity to prolong the lifespan of the grating, checking for wear and identifying points that may require reinforcement. Incorporating riveted grating into construction or renovation projects signals a commitment to quality, safety, and practicality. The inherent reliability and strength of this product make it an integral component of infrastructure that demands the highest standards. Across various applications, riveted grating continues to deliver uncompromised performance, earning its reputation as a trusted and authoritative choice in both design and implementation. For professionals dedicated to the creation of secure, durable, and efficient industrial environments, riveted grating remains a cornerstone of structural strategy.

Given the technical nature of riveted grating, those involved in its selection and installation must possess specialized knowledge. Choosing the correct size and spacing of the grating bars is crucial, impacting both the safety and functionality of the final installation. The expertise required to match the grating’s specifications to the project’s unique requirements underscores the importance of experienced engineering oversight. Additionally, installation demands a meticulous approach to ensure each component is correctly aligned and fastened, thereby preserving the structural integrity and longevity of the grating system. The authoritative voice in this domain relies heavily on hands-on experience. Installation teams with a proven track record in handling riveted grating bring invaluable insights that often preclude costly errors. Routine evaluations and maintenance checks guided by industry best practices further lend trust and assurance in the durability of installations utilizing riveted grating. Each inspection offers an opportunity to prolong the lifespan of the grating, checking for wear and identifying points that may require reinforcement. Incorporating riveted grating into construction or renovation projects signals a commitment to quality, safety, and practicality. The inherent reliability and strength of this product make it an integral component of infrastructure that demands the highest standards. Across various applications, riveted grating continues to deliver uncompromised performance, earning its reputation as a trusted and authoritative choice in both design and implementation. For professionals dedicated to the creation of secure, durable, and efficient industrial environments, riveted grating remains a cornerstone of structural strategy.

Share

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025