- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

فېۋرال . 14, 2025 03:18

Back to list

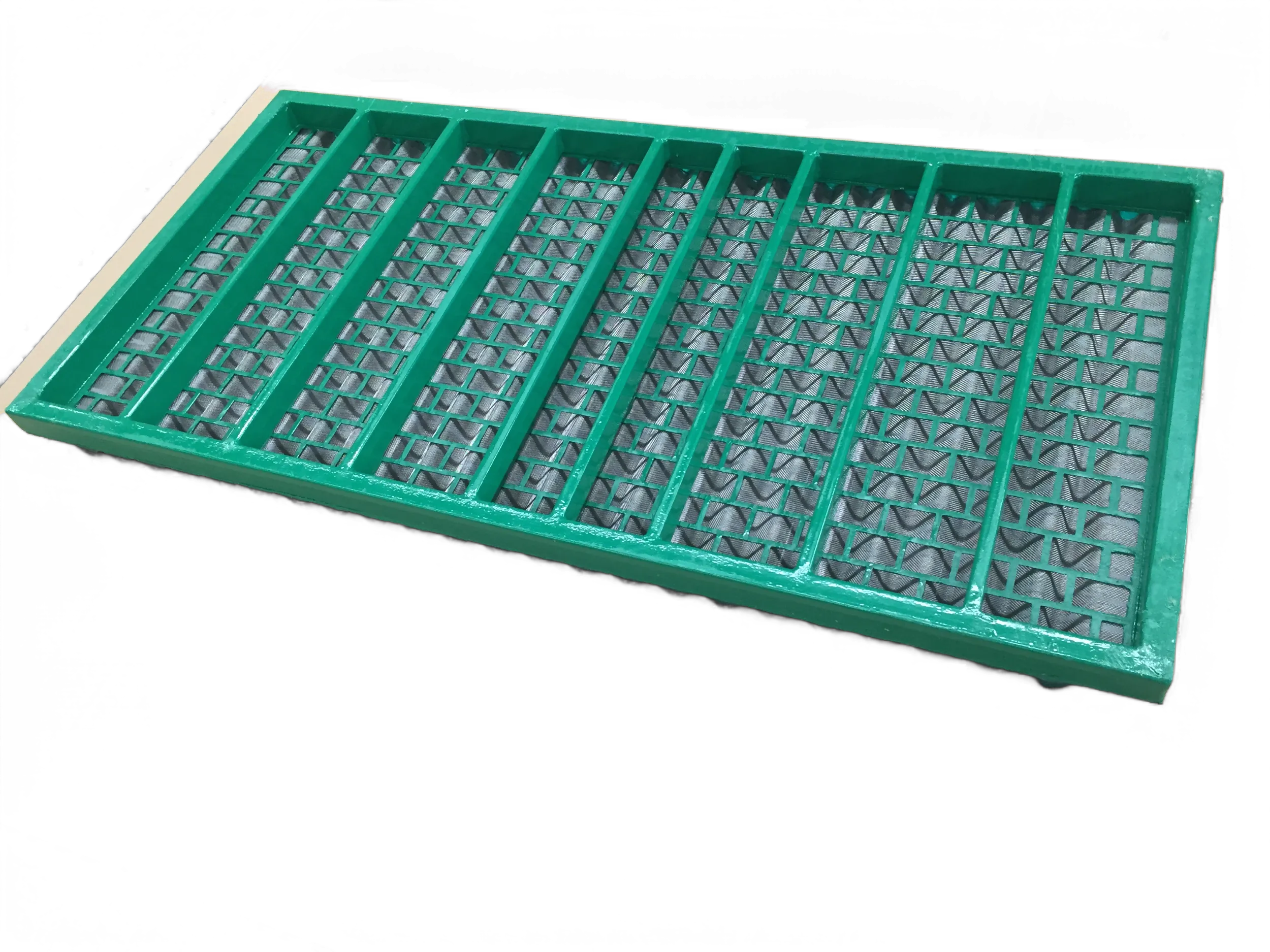

steel walkway grating

Steel grating, an essential component in many industries, offers a versatile solution for constructing robust platforms, walkways, and ventilation openings. From my extensive years of experience, I can assert that selecting the correct steel grating sizes markedly influences both the functionality and safety of the end application.

Customization in steel grating extends beyond mere dimensions. Surface treatment options such as galvanizing, painting, or powder coating are selected based on exposure conditions. My expertise confirms that, in coastal environments, galvanized coatings are indispensable for corrosion resistance. Moreover, adherence to industry standards and regulations cannot be understated. Familiarity with ASTM, ANSI, and other international standards ensures the grating products conform to requisite safety and performance measures. For instance, during a public infrastructure project, our team prioritized ASTM standards to guide grating specifications, ensuring compliance with governmental safety requirements. Quality manufacturers provide reliable data charts to assist in deciding on grating size based on load tables, deflection criteria, and span abilities. Comparing these specifications against actual project needs, backed by in-the-field measurements, is vital. My collaborations with leading manufacturers have demonstrated that their expertise often aids in troubleshooting potential issues before they arise during installation. Trustworthiness in steel grating solutions stems from transparency in production processes and adherence to high-quality control measures. Engaging with reputable suppliers known for rigorous testing protocols ensures the materials utilized will stand the test of time. In conclusion, selecting the correct steel grating sizes transcends mere specification adherence. It requires a nuanced balance of engineering expertise, real-world experience, and a commitment to quality and safety. Drawing on decades of experience, I affirm that investing the time in understanding these elements leads to sustainable and efficient infrastructure solutions, ensuring both performance excellence and safety assurance.

Customization in steel grating extends beyond mere dimensions. Surface treatment options such as galvanizing, painting, or powder coating are selected based on exposure conditions. My expertise confirms that, in coastal environments, galvanized coatings are indispensable for corrosion resistance. Moreover, adherence to industry standards and regulations cannot be understated. Familiarity with ASTM, ANSI, and other international standards ensures the grating products conform to requisite safety and performance measures. For instance, during a public infrastructure project, our team prioritized ASTM standards to guide grating specifications, ensuring compliance with governmental safety requirements. Quality manufacturers provide reliable data charts to assist in deciding on grating size based on load tables, deflection criteria, and span abilities. Comparing these specifications against actual project needs, backed by in-the-field measurements, is vital. My collaborations with leading manufacturers have demonstrated that their expertise often aids in troubleshooting potential issues before they arise during installation. Trustworthiness in steel grating solutions stems from transparency in production processes and adherence to high-quality control measures. Engaging with reputable suppliers known for rigorous testing protocols ensures the materials utilized will stand the test of time. In conclusion, selecting the correct steel grating sizes transcends mere specification adherence. It requires a nuanced balance of engineering expertise, real-world experience, and a commitment to quality and safety. Drawing on decades of experience, I affirm that investing the time in understanding these elements leads to sustainable and efficient infrastructure solutions, ensuring both performance excellence and safety assurance.

Share

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025