- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

مارت . 07, 2025 05:45

Back to list

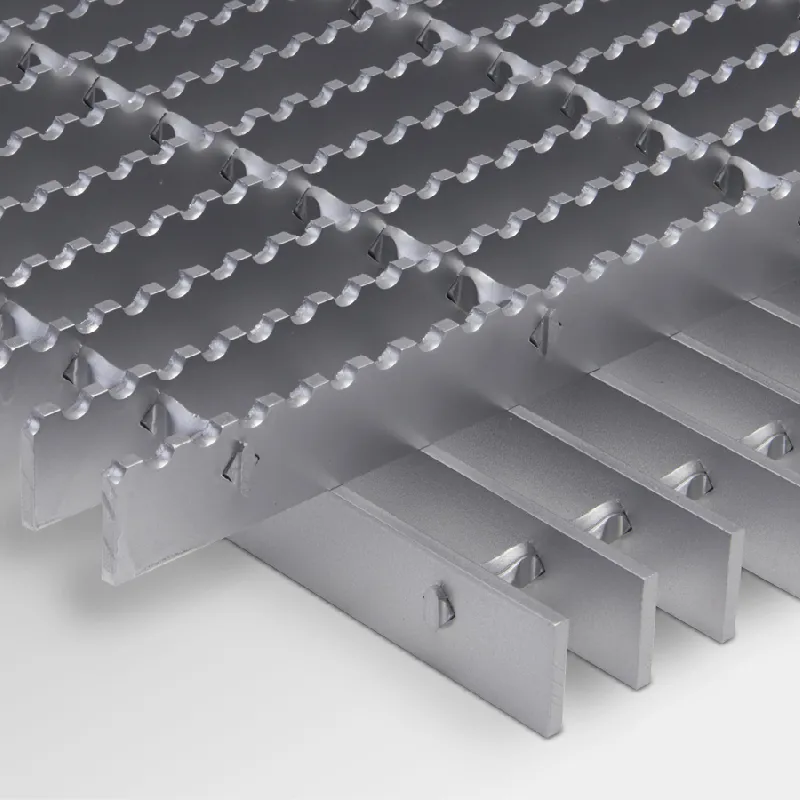

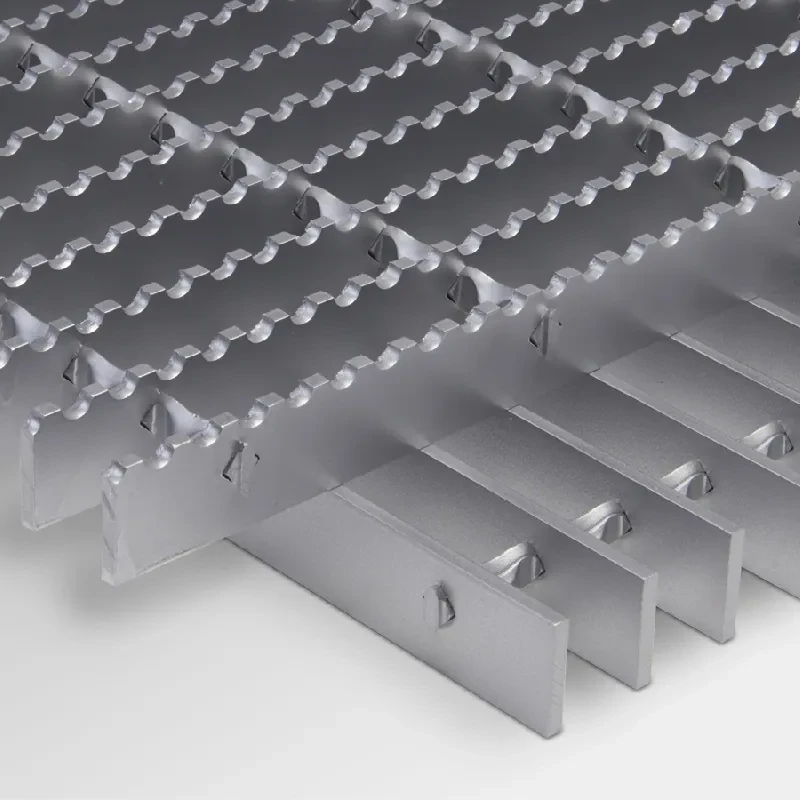

Press-Locked Steel Grating

When considering the cost implications of industrial flooring solutions, steel grating often emerges as a leading choice due to its durability, strength, and versatile applications. One of the key considerations for project managers and procurement specialists is understanding the price of steel grating per square meter. This price can fluctuate based on several factors, including raw materials, manufacturing techniques, and market demand. This article will delve into these facets, providing an in-depth understanding of what influences the cost and why steel grating remains a preferable solution.

Despite these variables, the investment in steel grating is often justified by its longevity and low maintenance costs. Unlike other flooring materials that may require frequent repairs or replacements, steel grating holds up under heavy loads and harsh conditions, providing safety and reliability over time. Its non-slip surface and self-cleaning properties make it ideal for industrial, commercial, and even residential projects. Building codes and safety standards also impact selection, as certain specifications of grating might be required to meet governmental regulations. Consulting with experts who understand local and international standards ensures compliance and maximizes the functionality and safety of the installed grating. In terms of return on investment, steel grating continues to prove its worth. Its ability to withstand environmental challenges with minimal degradation ensures it remains a cost-effective solution in the long run. Additionally, manufacturers offer various warranties and quality assurances which reflect the product's reliability and enhance trustworthiness for buyers. For those seeking a sustainable option, certain manufacturers have introduced recycled steel grating alternatives. These maintain the same structural integrity while promoting environmental responsibility—often at competitive pricing. Ultimately, understanding the nuances of steel grating pricing allows managers and engineers to make informed decisions that balance cost with functional requirements. Engaging with experienced suppliers who offer comprehensive consultation services can further enhance decision-making, ensuring that project requirements are met without compromising on quality or budget. Through careful planning and strategic sourcing, steel grating can serve as an effective solution for diverse flooring needs across multiple industries.

Despite these variables, the investment in steel grating is often justified by its longevity and low maintenance costs. Unlike other flooring materials that may require frequent repairs or replacements, steel grating holds up under heavy loads and harsh conditions, providing safety and reliability over time. Its non-slip surface and self-cleaning properties make it ideal for industrial, commercial, and even residential projects. Building codes and safety standards also impact selection, as certain specifications of grating might be required to meet governmental regulations. Consulting with experts who understand local and international standards ensures compliance and maximizes the functionality and safety of the installed grating. In terms of return on investment, steel grating continues to prove its worth. Its ability to withstand environmental challenges with minimal degradation ensures it remains a cost-effective solution in the long run. Additionally, manufacturers offer various warranties and quality assurances which reflect the product's reliability and enhance trustworthiness for buyers. For those seeking a sustainable option, certain manufacturers have introduced recycled steel grating alternatives. These maintain the same structural integrity while promoting environmental responsibility—often at competitive pricing. Ultimately, understanding the nuances of steel grating pricing allows managers and engineers to make informed decisions that balance cost with functional requirements. Engaging with experienced suppliers who offer comprehensive consultation services can further enhance decision-making, ensuring that project requirements are met without compromising on quality or budget. Through careful planning and strategic sourcing, steel grating can serve as an effective solution for diverse flooring needs across multiple industries.

Share

Prev:

Latest news

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025