- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

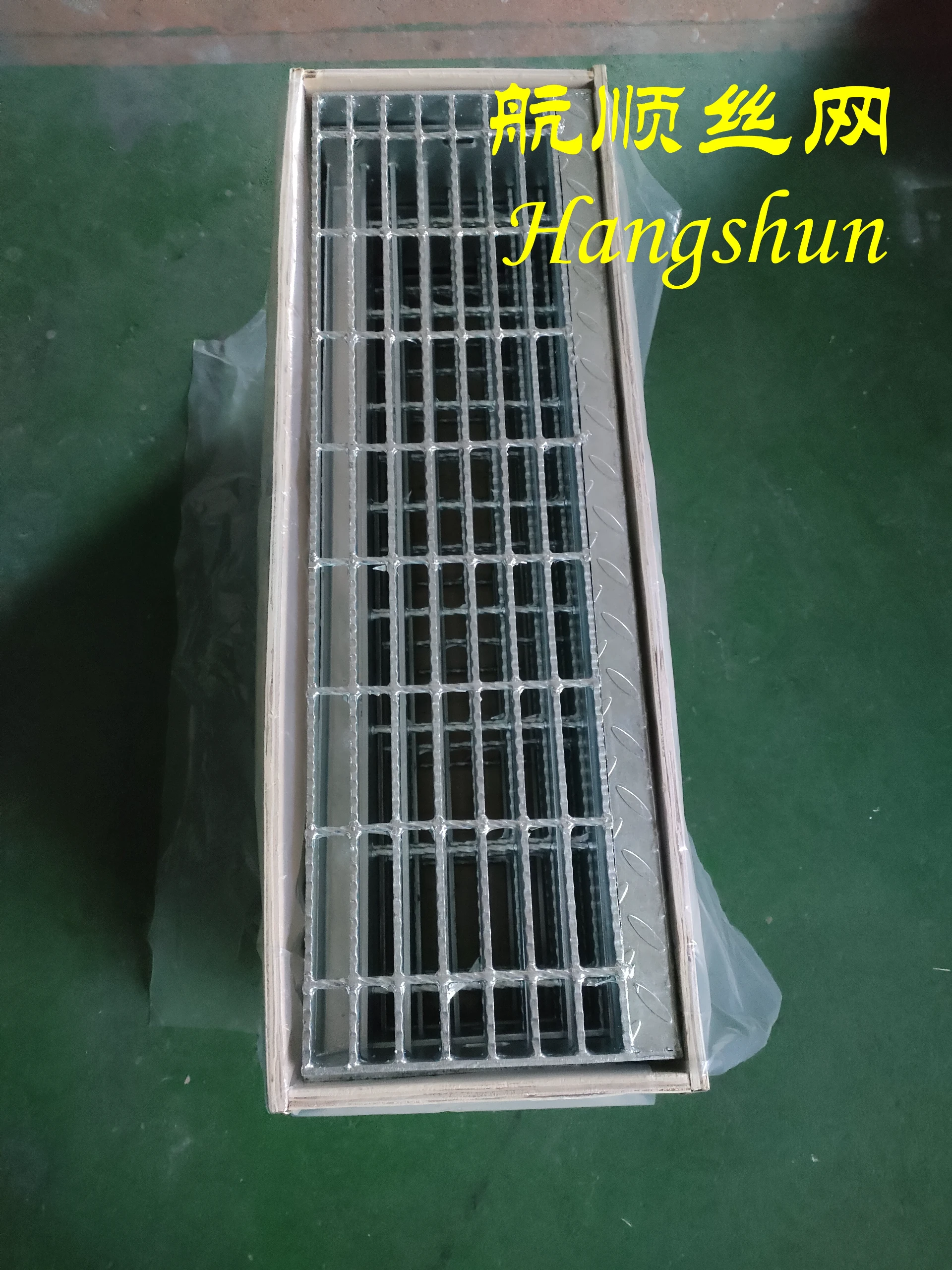

steel grating galvanis

Steel Grating Galvanization Enhancing Durability and Performance

Steel grating is a popular choice in various industrial and commercial applications, providing a versatile and durable solution for flooring, walkways, and supports. However, one of the most significant challenges that fabricators and users face is corrosion, which can severely undermine the longevity and safety of steel products. To combat this, galvanization has emerged as an effective method for enhancing the durability and performance of steel grating.

What is Galvanization?

Galvanization is a process that involves coating steel or iron with a layer of zinc to protect it from rust and corrosion. The process typically occurs through either hot-dipping or electroplating. In hot-dipping, the steel grating is immersed in molten zinc, resulting in a thick, corrosion-resistant coating that adheres strongly to the metal. Electroplating, on the other hand, uses an electrical current to deposit a thin layer of zinc onto the surface of the steel.

Benefits of Galvanized Steel Grating

1. Corrosion Resistance The primary advantage of galvanizing steel grating is its enhanced resistance to corrosion. By forming a protective barrier, galvanized steel grating can withstand exposure to harsh environmental conditions, including moisture, chemicals, and extreme temperatures. This is especially important in outdoor applications, where unprotected steel would likely rust within a short period.

2. Extended Lifespan The longevity of galvanized steel grating is significantly increased compared to non-galvanized options. While untreated steel may require replacement after a few years, galvanized steel can last for several decades, making it a cost-effective investment in the long run.

3. Low Maintenance Maintaining galvanized steel grating is relatively easy, requiring only occasional cleaning to remove dirt and debris. The zinc coating will continue to protect the steel beneath, reducing the need for regular maintenance and replacement, which can be time-consuming and expensive.

4. Improved Safety Safety is paramount in industrial settings, and galvanized steel grating can contribute to this by reducing the likelihood of slips and falls. Many types of grating are designed with anti-slip surfaces, and the corrosion resistance ensures that these surfaces remain safe over time without deteriorating.

steel grating galvanis

5. Environmental Considerations Galvanization is an environmentally friendly choice. The zinc coating is non-toxic and can be recycled. Moreover, by extending the life of steel products, galvanization reduces the frequency of replacement and waste, promoting a more sustainable practice within industries.

Applications of Galvanized Steel Grating

Galvanized steel grating is commonly used in various applications, from industrial facilities to commercial buildings. Some specific uses include

- Walkways and Platforms Many factories, warehouses, and outdoor installations utilize galvanized steel grating for walkways and platforms, offering safe and sturdy surfaces that are resistant to wear and tear. - Drainage Covers In environments where water drainage is crucial, galvanized steel grating serves as durable and reliable drainage covers, ensuring that debris does not obstruct flow while maintaining structural integrity.

- Stair treads and Ladders The use of galvanized grating for stair treads and ladders provides added safety through its anti-slip properties, critical in high-traffic or wet areas.

- Docks and Marinas The marine environment is notoriously harsh on materials, making galvanized steel grating an ideal choice for docks, piers, and marina structures, where exposure to saltwater significantly increases corrosion risks.

Conclusion

In conclusion, the galvanization of steel grating represents a vital advancement in materials engineering, allowing industries to utilize steel’s inherent strength without compromising on durability. With benefits ranging from corrosion resistance to low maintenance requirements, galvanized steel grating serves as an invaluable asset across multiple sectors. Emphasizing safety, longevity, and environmental sustainability, the popularity of galvanized steel grating is set to continue growing, driving innovation and efficiency in construction and industrial applications.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025