- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

shale shakerscreen manufacturers

Understanding the Role of Shale Shaker Screen Manufacturers in the Oil and Gas Industry

In the oil and gas industry, efficient drilling operations are paramount, and one of the critical components that play a vital role in this process is the shale shaker screen. These screens are integral to the separation of solids from drilling fluids, ensuring that the drilling process remains efficient and cost-effective. As the demand for oil and gas continues to rise, the importance of reliable shale shaker screen manufacturers cannot be overstated.

What are Shale Shaker Screens?

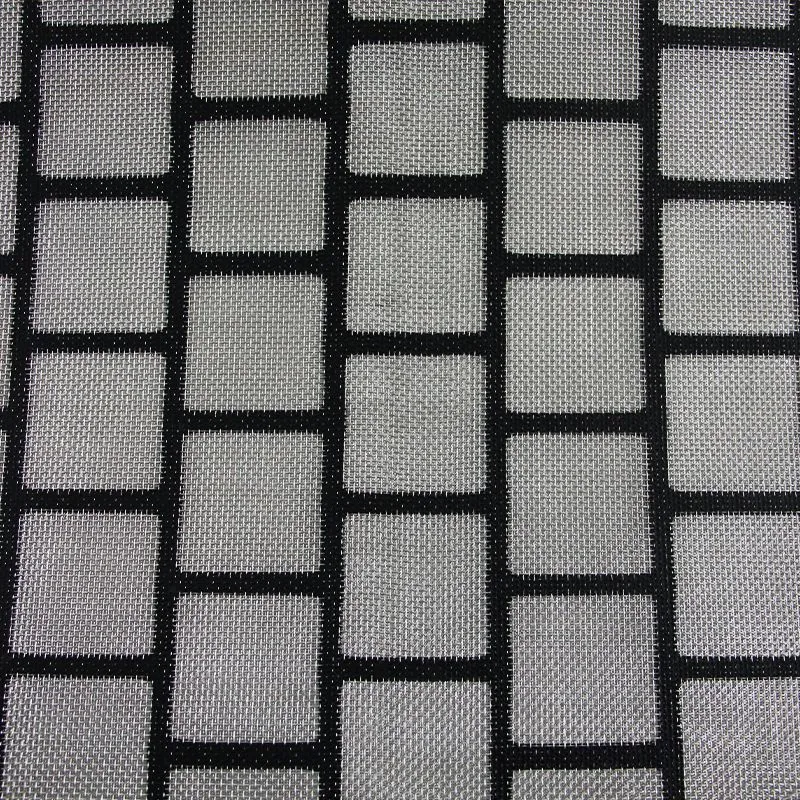

Shale shaker screens are filter elements used in shale shakers, a type of equipment that separates drill cuttings from the drilling fluid. During the drilling process, a drilling fluid, often referred to as mud, is circulated through the wellbore, carrying cuttings to the surface. The shale shaker utilizes a vibrational mechanism to facilitate the separation of these solids from the liquid. The efficiency of this process largely depends on the quality and design of the shaker screens.

These screens come in various mesh sizes, materials, and designs to cater to different drilling applications and fluid types. Manufacturers typically offer a range of products, including woven wire mesh screens, perforated plate screens, and composite screens, each suited for specific needs in the field.

The Role of Manufacturers

Shale shaker screen manufacturers have a crucial role in the oil and gas supply chain. Their responsibilities go beyond just producing screens; they also engage in research and technology development to improve the efficiency and durability of their products. High-quality screens can drastically reduce the volume of waste generated during the drilling process, lowering operational costs and environmental impact.

Moreover, in an industry where downtime can lead to significant financial losses, reliable manufacturers provide timely delivery and support services to ensure that drilling operations can continue without interruption. This reliability fosters long-term relationships between the manufacturers and drilling companies, which can be particularly beneficial in maintaining an uninterrupted workflow.

shale shakerscreen manufacturers

Innovations in Screen Technology

In recent years, there has been a growing trend toward innovation in shale shaker screen technology. The introduction of advanced materials, such as composite screens, has revolutionized the industry by offering greater durability and performance. These new materials ensure that screens can withstand the extreme conditions often found in drilling environments, including high pressure and abrasive materials.

Furthermore, manufacturers are investing in research and development to create screens that optimize fluid flow while maximizing solids removal efficiency. By incorporating advanced design techniques and technologies, manufacturers are able to produce screens that enhance the overall drilling performance.

Environmental Considerations

With growing environmental concerns associated with oil and gas extraction, manufacturers are also focusing on creating more sustainable products. The development of screens designed to minimize waste and improve fluid recovery aligns with the industry's push toward greener drilling practices. Manufacturers are increasingly adopting eco-friendly materials and processes, recognizing the importance of sustainability in maintaining a positive industry reputation.

Conclusion

In conclusion, shale shaker screen manufacturers are essential players in the oil and gas sector, directly impacting drilling efficiency, cost management, and environmental sustainability. As drilling technologies evolve and the demand for oil and gas rises, these manufacturers must continue innovating to meet the changing needs of the industry. By focusing on quality, reliability, and sustainability, they not only enhance the performance of shale shakers but also contribute to the overall efficiency and safety of drilling operations. As the landscape of the oil and gas industry continues to change, the role of these manufacturers will remain crucial in driving progress and innovation.

-

Welded Steel Grating: The Strong Foundation for Industrial SafetyNewsJul.16,2025

-

Strong and Safe: Swaged Grating SolutionsNewsJul.16,2025

-

Smart Choice For Industrial Safety MeshNewsJul.16,2025

-

Press-Locked Steel Grating: The Ultimate in Strength and SafetyNewsJul.16,2025

-

Keep Worksites Safer With Practical NettingNewsJul.16,2025

-

Helideck Safety Nets: Your First Line of DefenseNewsJul.16,2025