- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

فېۋرال . 20, 2025 10:42

Back to list

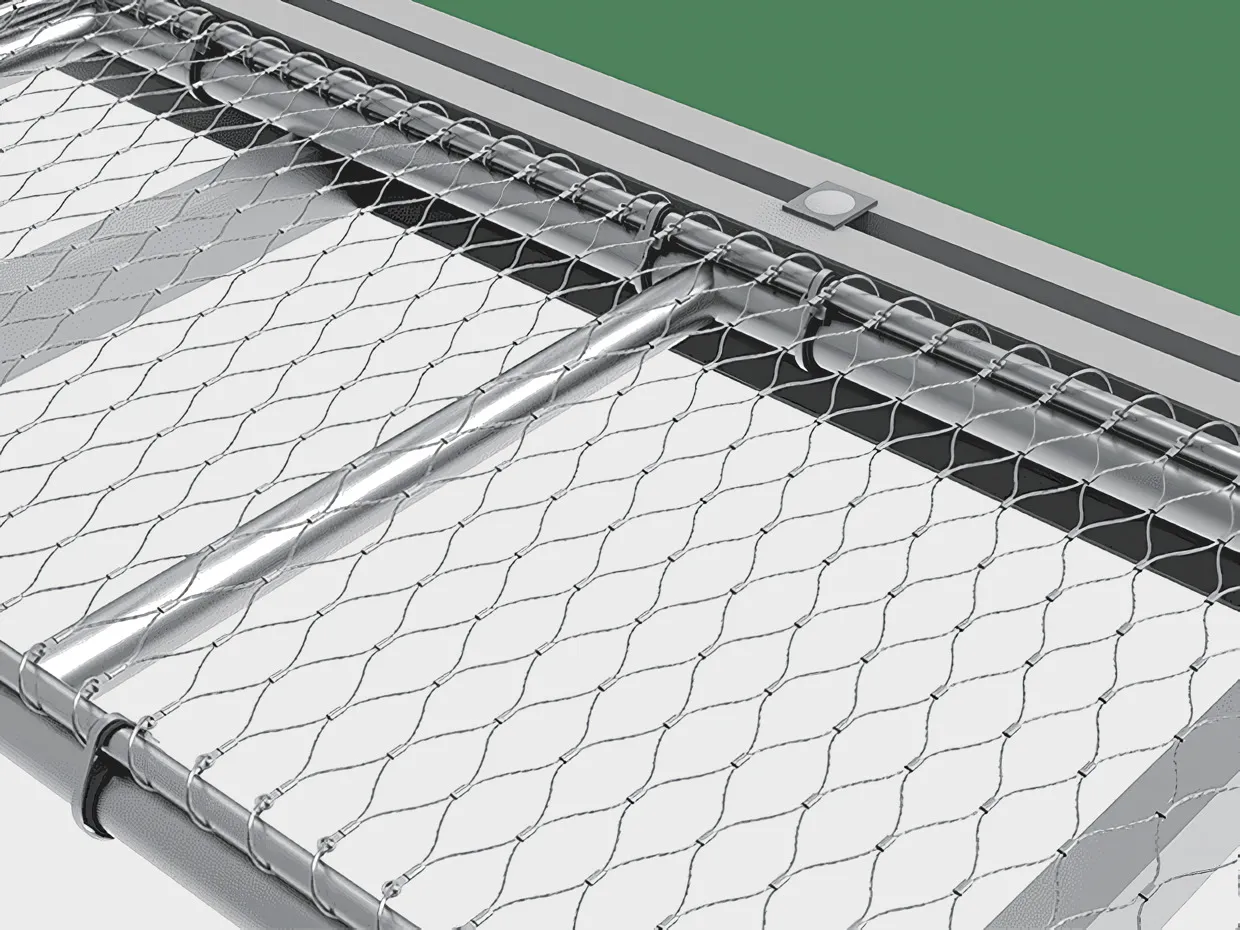

Composite Frame Shaker Screen

In the realm of industrial drilling and mining, shaker screens have emerged as quintessential components of efficient solid separation systems. These screens, crafted with precision and innovation, are instrumental in optimizing the performance of drilling operations and enhancing the longevity of other integral machinery. Understanding their construction, application, and benefits can significantly leverage operational efficacy in the energy sector and other industries that depend on solid-liquid separation processes.

The choice of a shaker screen involves more than just technical specifications; it also encompasses considerations of reliability and maintenance. High-quality shaker screens are built to withstand the harshest environments, ensuring continuous operation without frequent replacements. This reliability translates to increased uptime, less frequent interruptions, and a consistent operation flow. Moreover, the deployment of shaker screens aligns with environmentally responsible practices by minimizing waste and mitigating the environmental footprint of drilling operations. By efficiently separating solids, shaker screens significantly reduce the volume of waste, ensuring that only minimal refuse requires disposal. This not only complies with environmental regulations but also fosters sustainable industry practices. Just as crucial as the shaker screen's design and operational benefits is the expertise behind its integration into a broader system. Engaging with industry experts who understand not only the product but also the totality of its application ensures the full utilization of the technology. Experts can advise on the best practices for installation, maintenance, and replacement cycles, which greatly enhances the functional lifespan of shaker screens and reduces unforeseen downtimes. Furthermore, the industry emphasis on developing new materials and technologies promises ongoing innovations within the shaker screen domain. Advancements such as self-cleaning materials, hybrid designs integrating synthetic fibers, or enhanced structural designs aim to further increase efficiency and resilience. These innovations foster greater adaptability, allowing operators to handle increasingly complex drilling projects with precision and reduced risk. In conclusion, shaker screens are more than just a product; they symbolize a convergence of engineering expertise, operational efficiency, and environmental responsibility. By delivering exceptional performance and reliability, these screens are invaluable assets in the arsenal of any drilling or mining operation. Their continual evolution poised by ongoing research and development ensures that they will maintain their critical role in industry for years to come. By understanding and harnessing their capabilities, industries can achieve not only operational success but also sustainable industrial advancement.

The choice of a shaker screen involves more than just technical specifications; it also encompasses considerations of reliability and maintenance. High-quality shaker screens are built to withstand the harshest environments, ensuring continuous operation without frequent replacements. This reliability translates to increased uptime, less frequent interruptions, and a consistent operation flow. Moreover, the deployment of shaker screens aligns with environmentally responsible practices by minimizing waste and mitigating the environmental footprint of drilling operations. By efficiently separating solids, shaker screens significantly reduce the volume of waste, ensuring that only minimal refuse requires disposal. This not only complies with environmental regulations but also fosters sustainable industry practices. Just as crucial as the shaker screen's design and operational benefits is the expertise behind its integration into a broader system. Engaging with industry experts who understand not only the product but also the totality of its application ensures the full utilization of the technology. Experts can advise on the best practices for installation, maintenance, and replacement cycles, which greatly enhances the functional lifespan of shaker screens and reduces unforeseen downtimes. Furthermore, the industry emphasis on developing new materials and technologies promises ongoing innovations within the shaker screen domain. Advancements such as self-cleaning materials, hybrid designs integrating synthetic fibers, or enhanced structural designs aim to further increase efficiency and resilience. These innovations foster greater adaptability, allowing operators to handle increasingly complex drilling projects with precision and reduced risk. In conclusion, shaker screens are more than just a product; they symbolize a convergence of engineering expertise, operational efficiency, and environmental responsibility. By delivering exceptional performance and reliability, these screens are invaluable assets in the arsenal of any drilling or mining operation. Their continual evolution poised by ongoing research and development ensures that they will maintain their critical role in industry for years to come. By understanding and harnessing their capabilities, industries can achieve not only operational success but also sustainable industrial advancement.

Share

Latest news

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025