- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

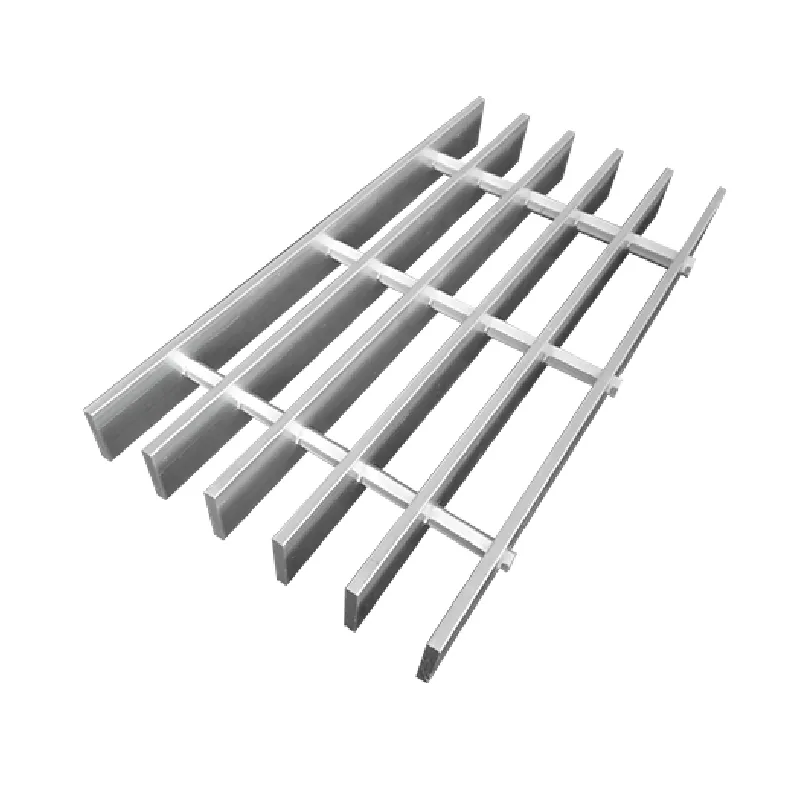

metal grating

The Future of Metal Grating Applications, Benefits, and Innovations

Metal grating is an essential component across various industries, serving vital functions in construction, manufacturing, and safety. Defined as a framework or structure made from metal strips that create a lattice-like pattern, metal grating offers a myriad of advantages, including durability, strength, and versatility. This article explores the applications, benefits, and innovative advancements in metal grating technologies, making it clear why it remains a critical asset in modern engineering.

Applications of Metal Grating

Metal grating can be found in a broad spectrum of applications. One of the most common uses is in flooring systems, especially in industrial settings. For instance, factories, warehouses, and refineries often employ metal grating for walkways, platforms, and staircases. These installations not only allow for safe passage but also provide excellent drainage capabilities—liquids can pass through the grating, reducing the risk of slips and falls.

In the construction sector, metal grating is commonly used in bridges and access covers. Its exceptional load-bearing capacity makes it an ideal choice for these structures, ensuring both safety and longevity. Additionally, in the marine industry, metal grating is used on docks and piers to enhance visibility and minimize slipping—attributes that are crucial in environments exposed to water.

Moreover, metal grating finds application in the electrical field, where it is often utilized as a grounding mechanism. By providing a low-resistance path for electric currents, it ensures stability and safety in various electronic and electrical installations.

Benefits of Metal Grating

The proliferation of metal grating can be attributed to its numerous benefits

. First and foremost is the strength-to-weight ratio for various metal types, including steel, aluminum, and stainless steel. These materials offer remarkable durability and resistance to wear and corrosion. Specifically, stainless steel grating is popular in environments subjected to harsh chemicals and moisture, as it withstands rust and degradation more effectively than other materials.Another significant benefit is its cost-effectiveness. While the initial investment may be higher than alternative materials, the longevity and minimal maintenance requirements of metal grating lead to reduced long-term costs. The open design of grating also allows for adequate airflow and light penetration, contributing to energy efficiency in buildings.

metal grating

Moreover, metal grating is customizable. Manufacturers can produce different sizes, shapes, and configurations to fit specific application needs. This customization capability allows industries to optimize their systems, ensuring that the metal grating solution is perfectly matched to their demands.

Innovations in Metal Grating

As technology progresses, so does the production and application of metal grating. Innovations in the manufacturing process have led to the development of advanced materials and coatings that enhance the performance of metal grating. For instance, composite materials are being explored for specific applications, offering the strength of metal while significantly reducing weight.

In addition, advancements in fabrication techniques have resulted in improved precision in cut and shape, which ensures that metal grating can be integrated seamlessly into existing systems. Enhanced welding technology provides greater structural integrity, ensuring that across various load applications, the performance is reliable.

Further, with growing concerns about sustainability, manufacturers are incorporating eco-friendly practices in the production of metal grating. This includes using recycled materials and reducing energy consumption during manufacturing processes. Such practices not only appeal to environmentally-conscious consumers but also contribute to a circular economy.

Lastly, automated installation techniques are being developed, reducing labor costs and time on-site. These innovations facilitate easier installation and replacement, which is necessary for industries that rely on efficiency and quick turnaround times.

Conclusion

The diverse applications, inherent benefits, and continuous innovations surrounding metal grating highlight its indispensable role in various industries. As technology progresses and industries evolve, metal grating systems will undoubtedly adapt and remain a crucial element in creating safe, functional, and sustainable environments. With its unmatched combination of strength, durability, and versatility, metal grating is poised to thrive in the modern landscape of engineering and construction for years to come.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025