- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

فېۋرال . 17, 2025 20:22

Back to list

perimeter safety netting

Ensuring optimal safety measures is a critical concern when it comes to aviation, especially in environments like helipads where landings and take-offs are frequent and potentially hazardous. One significant aspect of this safety framework is helipads perimeter safety netting. Designed to provide an additional layer of protection, these nettings prevent equipment and personnel from slipping off and ensure that any unexpected incidents are mitigated effectively. This article delves into the necessity, application, and specifications of perimeter safety netting for helipads, providing insights gleaned from industry experts and real-world applications that underline their significance.

Authoritative bodies in aviation safety continually update guidelines reflecting technological advancements and safety data, reinforcing the need for reliable safety net installations. Moreover, these updates ensure that perimeter safety netting remains at the cutting edge of protective technology, integrating new materials and designs that provide improved performance and resilience under operational stresses. Trustworthiness in the choice and installation of perimeter safety netting begins with selecting reputable manufacturers and suppliers who can offer products certified by relevant authorities. It is paramount that the materials used in netting solutions are traceable and meet the rigorous standards set forth for aviation safety equipment. Additionally, regular inspections and maintenance schedules, conducted by certified professionals, ensure compliance and functionality over the lifespan of the installation. In conclusion, the importance of helipads perimeter safety netting to the aviation sector cannot be understated. It acts as a silent guardian, deterring potential accidents and ensuring that operations proceed smoothly without incident. Coupled with expert installation and ongoing maintenance, these netting systems stand as a testament to aviation's commitment to safety and reliability. From enhancing the structural safety of landing zones to embodying the latest in protective technology, perimeter safety netting remains a cornerstone of secure aviation infrastructure.

Authoritative bodies in aviation safety continually update guidelines reflecting technological advancements and safety data, reinforcing the need for reliable safety net installations. Moreover, these updates ensure that perimeter safety netting remains at the cutting edge of protective technology, integrating new materials and designs that provide improved performance and resilience under operational stresses. Trustworthiness in the choice and installation of perimeter safety netting begins with selecting reputable manufacturers and suppliers who can offer products certified by relevant authorities. It is paramount that the materials used in netting solutions are traceable and meet the rigorous standards set forth for aviation safety equipment. Additionally, regular inspections and maintenance schedules, conducted by certified professionals, ensure compliance and functionality over the lifespan of the installation. In conclusion, the importance of helipads perimeter safety netting to the aviation sector cannot be understated. It acts as a silent guardian, deterring potential accidents and ensuring that operations proceed smoothly without incident. Coupled with expert installation and ongoing maintenance, these netting systems stand as a testament to aviation's commitment to safety and reliability. From enhancing the structural safety of landing zones to embodying the latest in protective technology, perimeter safety netting remains a cornerstone of secure aviation infrastructure.

Share

Prev:

Latest news

-

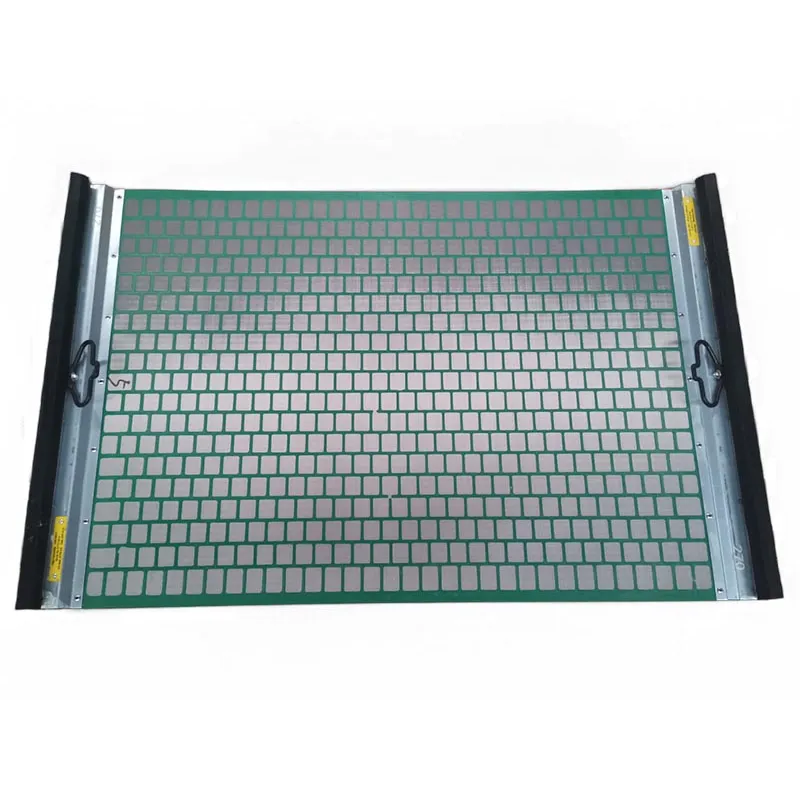

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

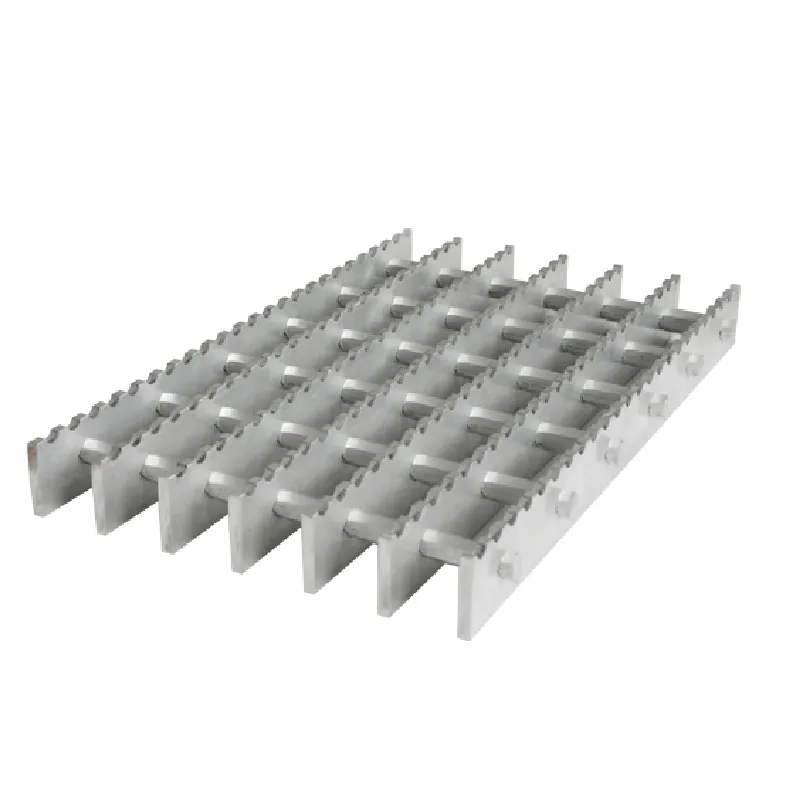

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025