- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

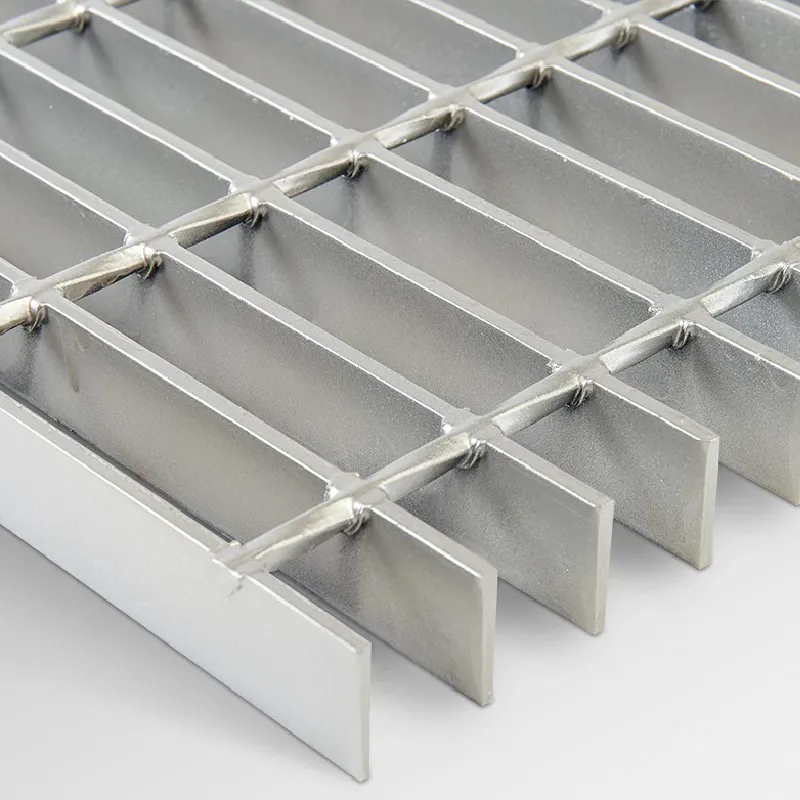

grating hot dip galvanized

Understanding Grating and Hot-Dip Galvanization

Grating is a crucial component in various industrial, commercial, and infrastructure applications. It refers to a framework of parallel or crossed bars, often made from metal, which creates a surface with open spaces that allow for drainage, ventilation, and light access. One of the most widely used forms of grating is steel grating, which can be subjected to many environmental conditions and loads. To increase its durability and lifespan, steel grating is often treated with hot-dip galvanization.

What is Hot-Dip Galvanization?

Hot-dip galvanization is a process in which iron or steel products are immersed in a molten zinc bath, allowing for the formation of a protective zinc coating. This method is highly regarded for its ability to provide a robust and long-lasting barrier against corrosion. The process involves several stages, including surface cleaning, pre-treatment, dipping in molten zinc, and cooling.

The effectiveness of hot-dip galvanization lies in the metallurgical bonding formed between the zinc and the steel. The resulting coating is typically thicker than that achieved through other galvanizing methods, providing exceptional corrosion resistance that can last for decades even in the harshest environments.

Applications of Grating

Grating finds its applications in numerous fields, including

1. Industrial Facilities In factories, grating is used for walkways, platforms, and drainage systems. It provides a safe walking surface while allowing liquids to pass through, reducing slip hazards. 2. Staircases and Ramps For outdoor and indoor staircases, grating can offer slip resistance and structural support without being overly heavy.

grating hot dip galvanized

4. Wastewater Treatment Grating is integral to wastewater treatment facilities. It helps to support machinery while allowing for efficient water movement and waste removal.

Benefits of Hot-Dip Galvanized Grating

1. Corrosion Resistance One of the primary advantages of hot-dip galvanized grating is its exceptional resistance to corrosion. The zinc coating protects the steel beneath from rust and environmental damage, making it suitable for outdoor use in various settings, from marine environments to chemical plants.

2. Longevity The thick zinc layer extending the life of the grating. Many installations boast lifespans exceeding 50 years without significant maintenance, which translates to long-term cost savings.

3. Low Maintenance Hot-dip galvanized grating requires minimal upkeep. Unlike paint coatings which may chip or wear over time, the galvanized surface handles wear and does not need regular reapplication.

4. Enhanced Safety The open design of grating, combined with the durability of the galvanized coating, provides safe walking surfaces while ensuring that liquids can drain away, thus reducing slip hazards.

5. Aesthetic Appeal Hot-dip galvanized surfaces maintain a clean and uniform appearance. While some may perceive galvanized metal as industrial or utilitarian, modern design often incorporates these elements for a contemporary look.

Conclusion

In summary, grating and hot-dip galvanization represent a powerful combination for creating durable and safe surfaces in a multitude of applications. As industries continue to recognize the importance of reliable and long-lasting infrastructure, the use of hot-dip galvanized grating stands out as a practical solution that meets both functional and economic needs. Its myriad benefits, including corrosion resistance, longevity, low maintenance, safety, and aesthetic appeal, ensure that it will remain a staple in engineering and construction for years to come. Whether in industrial settings or urban infrastructure, hot-dip galvanized grating is poised to continue playing a vital role in modern applications.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025