- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

فېۋرال . 18, 2025 00:34

Back to list

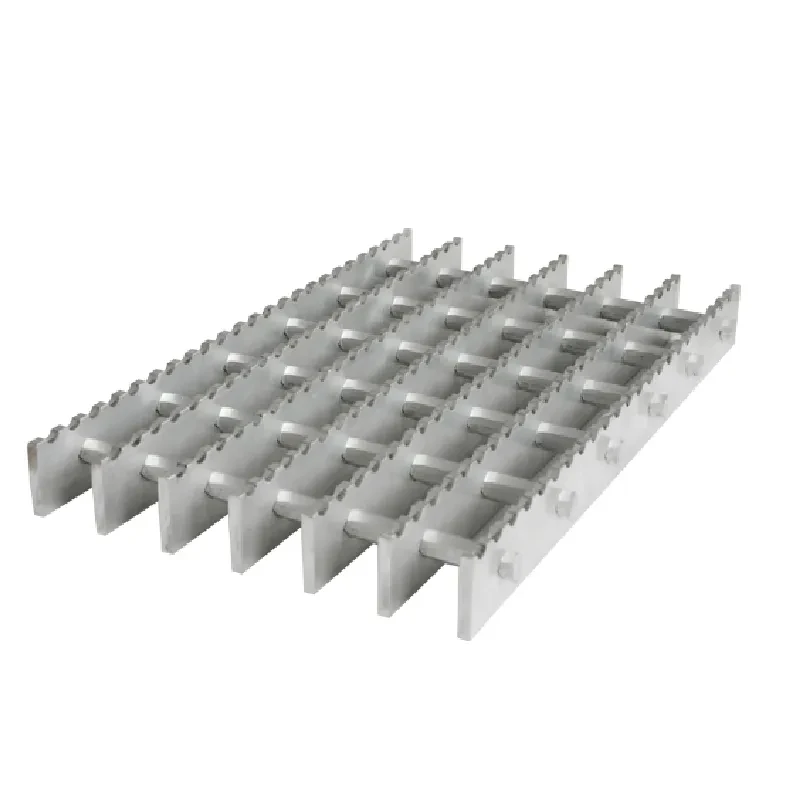

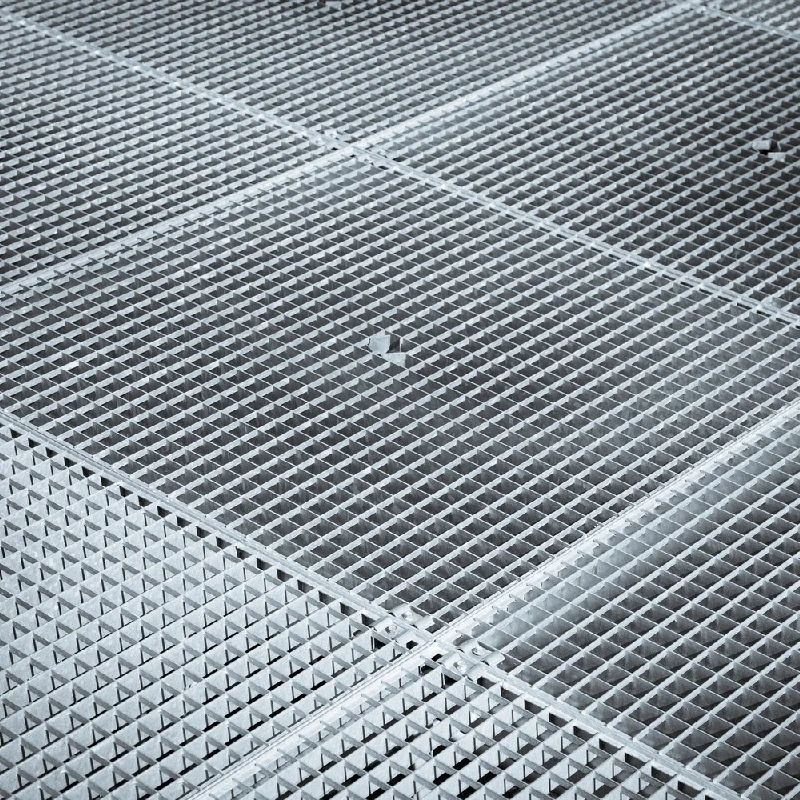

Swage-Locked Steel Grating

Galvanized grating is a pivotal material in many industrial and commercial applications, offering durability, safety, and cost-effectiveness in high-demand environments. Its versatility and resilience stem from the process of galvanization, which involves coating steel or iron gratings with a layer of zinc to prevent corrosion. This process extends the lifespan of the grating, making it an ideal choice for sectors needing reliable structures that can withstand harsh environmental conditions.

Authoritativeness in the production of galvanized grating is maintained by manufacturers adhering to international standards such as ASTM A123 for zinc coatings and ASTM A36 for carbon structural steel. This compliance ensures that each piece meets specific thickness and weight requirements, offering consistent quality and performance in demanding situations. Consumers seeking assurance of trustworthiness should prioritize suppliers with certification and a well-documented quality control process, affirming that their grating will perform as expected under various operational conditions. When purchasing galvanized grating, consumers benefit from considering both the environmental and economic aspects. The process of galvanizing steel is not only effective but also sustainable. Zinc, being a naturally occurring element, is not harmful to the environment when managed correctly. Additionally, the longevity of galvanized grating substantially decreases the need for resource-intensive replacements, contributing positively to long-term environmental sustainability. For businesses looking to invest in galvanized grating, it is crucial to work with experienced suppliers who can provide customized solutions tailored to specific project requirements. Expert suppliers can guide the selection process based on load demands, design specifications, and environmental conditions, ensuring optimal performance and safety. In conclusion, galvanized grating holds an esteemed place in industrial applications due to its unparalleled durability, safety features, and cost-effectiveness. Its resistance to corrosion and adaptability across various environments underscores its value as a resourceful and sustainable option. By aligning with reputable manufacturers and suppliers, businesses can assure the incorporation of galvanized grating into their infrastructure, promising enhanced safety and longevity.

Authoritativeness in the production of galvanized grating is maintained by manufacturers adhering to international standards such as ASTM A123 for zinc coatings and ASTM A36 for carbon structural steel. This compliance ensures that each piece meets specific thickness and weight requirements, offering consistent quality and performance in demanding situations. Consumers seeking assurance of trustworthiness should prioritize suppliers with certification and a well-documented quality control process, affirming that their grating will perform as expected under various operational conditions. When purchasing galvanized grating, consumers benefit from considering both the environmental and economic aspects. The process of galvanizing steel is not only effective but also sustainable. Zinc, being a naturally occurring element, is not harmful to the environment when managed correctly. Additionally, the longevity of galvanized grating substantially decreases the need for resource-intensive replacements, contributing positively to long-term environmental sustainability. For businesses looking to invest in galvanized grating, it is crucial to work with experienced suppliers who can provide customized solutions tailored to specific project requirements. Expert suppliers can guide the selection process based on load demands, design specifications, and environmental conditions, ensuring optimal performance and safety. In conclusion, galvanized grating holds an esteemed place in industrial applications due to its unparalleled durability, safety features, and cost-effectiveness. Its resistance to corrosion and adaptability across various environments underscores its value as a resourceful and sustainable option. By aligning with reputable manufacturers and suppliers, businesses can assure the incorporation of galvanized grating into their infrastructure, promising enhanced safety and longevity.

Share

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025