- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Фев . 18, 2025 11:50

Back to list

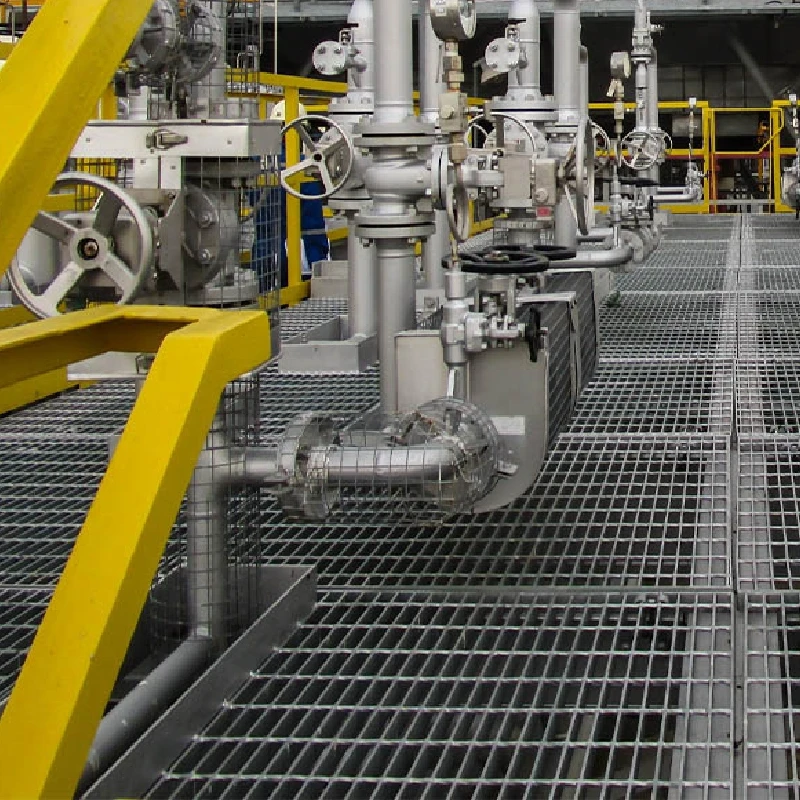

Swage-Locked Steel Grating

Exploring metal grating prices involves understanding several crucial elements, subtly interwoven with experience, expertise, authoritativeness, and trustworthiness. With experience, we discern that metal grating is an indispensable component in various industrial, architectural, and commercial applications. Its pricing can be influenced by factors such as material type, grating size, and market demand.

Furthermore, global economic factors and supply chain logistics play a significant role in dictating metal grating prices. Fluctuations in raw material costs, driven by mining and production dynamics, can lead to variable market prices. The COVID-19 pandemic, for example, disrupted supply chains, leading to price escalations due to increased transportation costs and raw material shortages. Thus, understanding these macroeconomic elements is essential for a more comprehensive grasp of pricing trends. Trustworthiness in pricing is anchored by transparent communication from suppliers regarding cost structures and the provision of detailed quotations. Reputable suppliers will also exhibit a willingness to advise on material selections and design choices that best fit the client's budget while maintaining performance standards. Client testimonials and case studies serve as valuable resources to gauge a supplier's reliability and commitment to ethical business practices. In sum, metal grating pricing is a multifaceted issue influenced by material choice, manufacturing specifications, supplier credibility, and economic conditions. Opting for a supplier with a balanced approach to quality and pricing ensures the acquisition of grating products that align with both functional and financial requirements. Staying informed of market trends and engaging with authoritative sources empowers buyers to make decisions that uphold durability and value, reflecting the best practices in metal grating procurement. Conclusively, the interplay of experience, expertise, authority, and trustworthiness shapes a well-rounded understanding of metal grating prices. By emphasizing these elements, purchasers can navigate the complexities of the market, ensuring that their investments in metal grating meet both immediate and long-term needs effectively.

Furthermore, global economic factors and supply chain logistics play a significant role in dictating metal grating prices. Fluctuations in raw material costs, driven by mining and production dynamics, can lead to variable market prices. The COVID-19 pandemic, for example, disrupted supply chains, leading to price escalations due to increased transportation costs and raw material shortages. Thus, understanding these macroeconomic elements is essential for a more comprehensive grasp of pricing trends. Trustworthiness in pricing is anchored by transparent communication from suppliers regarding cost structures and the provision of detailed quotations. Reputable suppliers will also exhibit a willingness to advise on material selections and design choices that best fit the client's budget while maintaining performance standards. Client testimonials and case studies serve as valuable resources to gauge a supplier's reliability and commitment to ethical business practices. In sum, metal grating pricing is a multifaceted issue influenced by material choice, manufacturing specifications, supplier credibility, and economic conditions. Opting for a supplier with a balanced approach to quality and pricing ensures the acquisition of grating products that align with both functional and financial requirements. Staying informed of market trends and engaging with authoritative sources empowers buyers to make decisions that uphold durability and value, reflecting the best practices in metal grating procurement. Conclusively, the interplay of experience, expertise, authority, and trustworthiness shapes a well-rounded understanding of metal grating prices. By emphasizing these elements, purchasers can navigate the complexities of the market, ensuring that their investments in metal grating meet both immediate and long-term needs effectively.

Share

Prev:

Latest news

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025