- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

galvanised grating

The Versatility and Benefits of Galvanised Grating

Galvanised grating is a vital component in various industrial and commercial applications, offering a perfect blend of strength, durability, and versatility. This type of grating is primarily made from steel that has been coated with a layer of zinc through a process known as galvanization. The result is a product that resists corrosion and wear, making it ideal for environments where exposure to moisture and chemical elements is a concern.

One of the main advantages of galvanised grating is its exceptional resistance to rust and corrosion. In industries such as oil and gas, waste treatment, and chemical processing, where corrosive substances are often handled, galvanised grating stands out as a reliable choice. The zinc coating acts as a protective barrier, ensuring the underlying steel is shielded from the elements. This not only extends the lifespan of the grating but also reduces maintenance costs, making it a cost-effective solution in the long run.

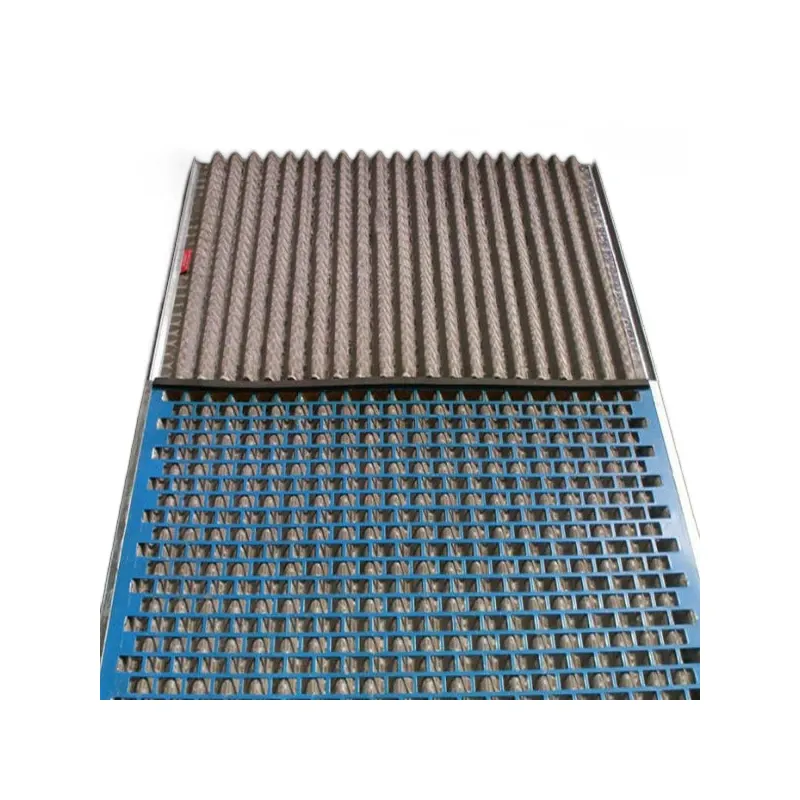

Additionally, galvanised grating is known for its high load-bearing capacity. It is available in various designs and configurations, including bar grating, plank grating, and serrated options, which cater to specific load requirements and applications. The open design of the grating allows for excellent drainage, making it ideal for areas prone to spills or water accumulation. This feature is particularly beneficial in industrial settings where safety is a paramount concern, as it minimizes the risk of slips and falls.

galvanised grating

Moreover, galvanised grating is lightweight yet robust, making it easy to handle and install. Its modular design allows for quick assembly and adaptability to different areas of a facility. This ease of installation further enhances its appeal, particularly in sectors where downtime needs to be minimized. In addition to practical setups, galvanised grating is often aesthetically pleasing, offering a clean and professional look that can be important in commercial applications.

The environmental benefits of galvanised grating should not be overlooked either. The galvanization process makes use of recyclable materials, and the product itself is 100% recyclable at the end of its life cycle. This aligns with the growing emphasis on sustainability within various industries, making galvanised grating a responsible choice for environmentally conscious companies.

In terms of maintenance, galvanised grating is exceptionally low-maintenance compared to other options. While wooden grating may rot and require regular replacement, and fiberglass may deteriorate under certain chemical exposures, galvanised steel maintains its structural integrity with minimal upkeep. Occasional cleaning and inspection are generally all that is needed to ensure it remains in optimal condition.

In conclusion, galvanised grating is an indispensable material across various sectors due to its unique combination of properties. Its resistance to rust, robust load-bearing capabilities, lightweight nature, and low maintenance requirements make it a preferred choice in settings where safety, durability, and cost-effectiveness are critical. As industries continue to evolve and emphasize sustainability, galvanised grating will undoubtedly maintain its relevance and popularity as a reliable and versatile solution. Whether for walkways, platforms, or drainage, galvanised grating is a smart investment for any facility looking to enhance both safety and efficiency.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025