- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oca . 09, 2025 10:41

Back to list

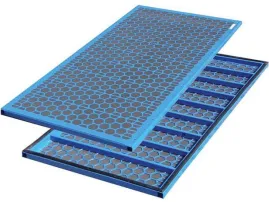

Offshore Pipeline Counterweight Welded Wire Mesh

Steel pipe winding mesh represents an innovative leap in the realm of construction and industrial applications. This technology is an embodiment of precision engineering catering to the bolstering demands of modern infrastructure. To comprehend the full breadth of its capabilities and benefits, it's crucial to draw insights from real-world applications and expert opinions.

Authoritative endorsements stem from its compliance with international quality standards, which add to its credibility. Certification from leading industry boards guarantees that this solution meets the rigorous demands of modern construction. Moreover, its antibacterial and anti-corrosive coatings enhance the mesh's durability, ensuring that structures remain sound over extended periods, especially in challenging climates. Trust in steel pipe winding mesh is further solidified by testimonials from industry leaders who have witnessed its performance. Jason Li, a reputable construction project manager, recounts his experience on a multi-million dollar infrastructural project. He recalled, We were initially skeptical about moving away from conventional reinforcements. However, the seamless integration of the steel pipe winding mesh in our projects resulted in fewer structural delays and unforeseen maintenance issues post completion. Investment in this technology also aligns with eco-friendly construction practices. Given that it can significantly reduce the overall volume of concrete and steel usage, the environmental footprint of projects is markedly lower. This attribute caters to a growing sector of environmentally conscious stakeholders willing to explore sustainable building solutions. In conclusion, the steel pipe winding mesh promises to be a revolutionary part of the construction industry due to its innovative design, formidable strength, and versatile applications—a statement backed by empirical evidence and expert validation. As the demand for sustainable and resilient infrastructures continues to rise, its role is set to amplify, establishing it as a mainstay in future project planning and execution.

Authoritative endorsements stem from its compliance with international quality standards, which add to its credibility. Certification from leading industry boards guarantees that this solution meets the rigorous demands of modern construction. Moreover, its antibacterial and anti-corrosive coatings enhance the mesh's durability, ensuring that structures remain sound over extended periods, especially in challenging climates. Trust in steel pipe winding mesh is further solidified by testimonials from industry leaders who have witnessed its performance. Jason Li, a reputable construction project manager, recounts his experience on a multi-million dollar infrastructural project. He recalled, We were initially skeptical about moving away from conventional reinforcements. However, the seamless integration of the steel pipe winding mesh in our projects resulted in fewer structural delays and unforeseen maintenance issues post completion. Investment in this technology also aligns with eco-friendly construction practices. Given that it can significantly reduce the overall volume of concrete and steel usage, the environmental footprint of projects is markedly lower. This attribute caters to a growing sector of environmentally conscious stakeholders willing to explore sustainable building solutions. In conclusion, the steel pipe winding mesh promises to be a revolutionary part of the construction industry due to its innovative design, formidable strength, and versatile applications—a statement backed by empirical evidence and expert validation. As the demand for sustainable and resilient infrastructures continues to rise, its role is set to amplify, establishing it as a mainstay in future project planning and execution.

Share

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025