- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 18, 2025 01:27

Back to list

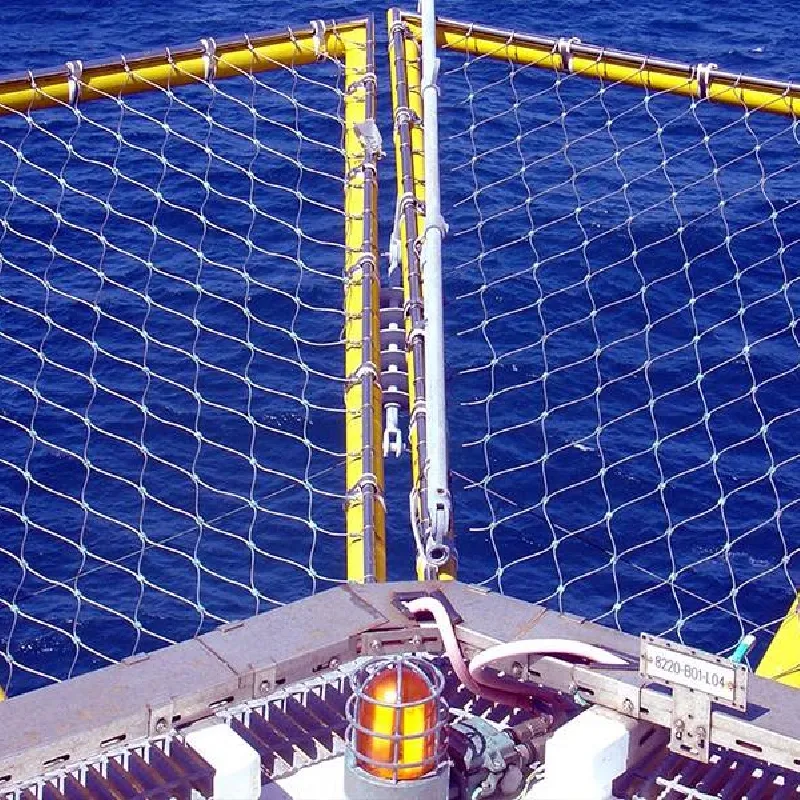

Swage-Locked Steel Grating

Steel grating is a crucial component in various industries due to its versatility, durability, and unique features that make it suitable for a wide range of applications. Understanding the different types of steel grating available can significantly impact the choice for specific projects, ensuring both safety and efficiency.

In addition to manufacturing methods, steel grating can also be categorized by the shape and size of the bars used. Serrated steel grating, for example, enhances slip resistance, making it ideal for wet or oily environments. Standard grating, with its flat, rectangular bars, is often easier to clean and maintain, which is suitable for areas such as food processing plants where cleanliness is paramount. Material choice also plays a significant role in determining the type of steel grating. Carbon steel, stainless steel, and aluminum are common materials used, each offering different advantages. Carbon steel is often used for its cost-effectiveness and strength. Stainless steel provides excellent corrosion resistance, which is crucial in chemical processing environments. Meanwhile, aluminum offers a lightweight alternative that is perfect for applications requiring ease of installation and handling. Understanding these different aspects of steel grating is essential in selecting the appropriate type for a project. Consulting with experts in the field can provide invaluable insights, ensuring the chosen grating meets safety standards and project requirements. Experts bring a wealth of knowledge and can guide decision-making based on years of experience, offering solutions that are both innovative and practical. By choosing the right type of steel grating, businesses not only ensure compliance with safety regulations but also enhance operational efficiency and longevity of their infrastructure. A willingness to invest time and resources into understanding these products will likely yield significant returns, underscoring the importance of making informed decisions in industrial and commercial development. Ultimately, the choice of steel grating can affect various facets of a project, from cost and safety to maintenance and aesthetics. With an informed approach, businesses can maximize the benefits of steel grating, ensuring their infrastructure remains resilient and effective in all scenarios.

In addition to manufacturing methods, steel grating can also be categorized by the shape and size of the bars used. Serrated steel grating, for example, enhances slip resistance, making it ideal for wet or oily environments. Standard grating, with its flat, rectangular bars, is often easier to clean and maintain, which is suitable for areas such as food processing plants where cleanliness is paramount. Material choice also plays a significant role in determining the type of steel grating. Carbon steel, stainless steel, and aluminum are common materials used, each offering different advantages. Carbon steel is often used for its cost-effectiveness and strength. Stainless steel provides excellent corrosion resistance, which is crucial in chemical processing environments. Meanwhile, aluminum offers a lightweight alternative that is perfect for applications requiring ease of installation and handling. Understanding these different aspects of steel grating is essential in selecting the appropriate type for a project. Consulting with experts in the field can provide invaluable insights, ensuring the chosen grating meets safety standards and project requirements. Experts bring a wealth of knowledge and can guide decision-making based on years of experience, offering solutions that are both innovative and practical. By choosing the right type of steel grating, businesses not only ensure compliance with safety regulations but also enhance operational efficiency and longevity of their infrastructure. A willingness to invest time and resources into understanding these products will likely yield significant returns, underscoring the importance of making informed decisions in industrial and commercial development. Ultimately, the choice of steel grating can affect various facets of a project, from cost and safety to maintenance and aesthetics. With an informed approach, businesses can maximize the benefits of steel grating, ensuring their infrastructure remains resilient and effective in all scenarios.

Share

Prev:

Latest news

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025