- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 15, 2025 00:28

Back to list

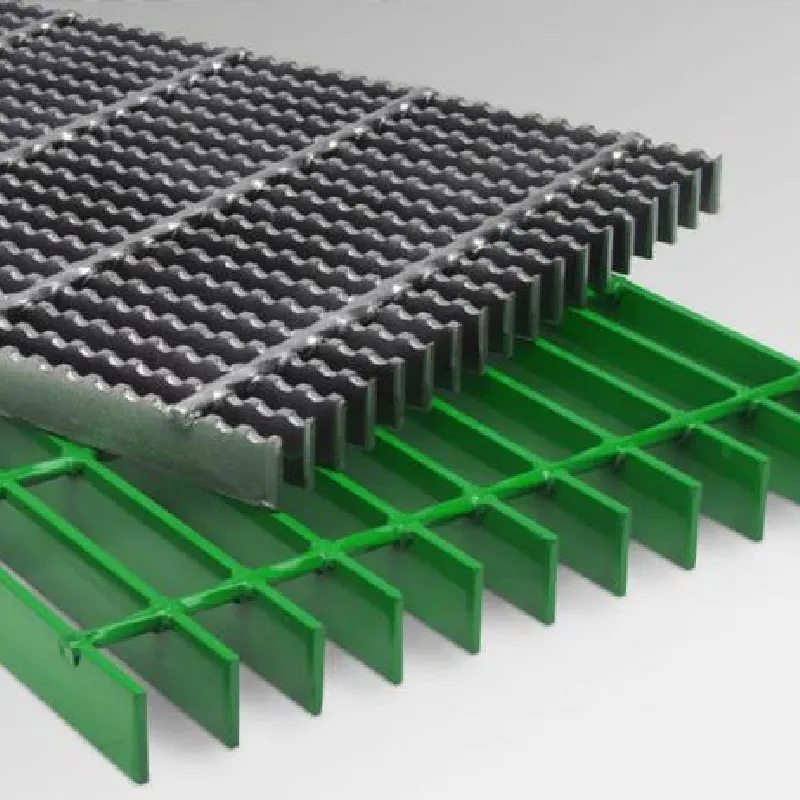

steel bar grating weight

Understanding the weight of steel bar grating is crucial for applications across numerous industries, from construction to manufacturing. It plays a vital role not only in the selection process but also in the logistics and design considerations of any project. Engineers, architects, and project managers alike must appreciate the intricacies that account for the weight to ensure safety, efficiency, and cost-effectiveness.

When calculating the specific weight of a steel bar grating, professionals often refer to manufacturer’s specification sheets or use established formulas that consider these variables. The weight is usually expressed in pounds per square foot (PSF) or kilograms per square meter (KGM), providing a standardized measure for comparison and selection. Accurate weight estimation not only influences the design but also affects the transportation and installation processes. Heavy gratings may require specialized equipment for lifting and installation, thereby impacting the overall project timeline and costs. Therefore, an adept understanding of the interactions between material choice, dimensions, and spacing can facilitate more informed decision-making to enhance project efficiency. In conclusion, the weight of steel bar grating is a core consideration that impacts the functionality and economics of a project. Industry professionals must engage with manufacturers and leverage technical specifications to select the most suitable grating type. By doing so, they ensure that their projects benefit from optimally balanced weight, strength, and durability, thereby achieving both structural and economic goals. This comprehensive approach not only facilitates compliance with safety standards but also fosters innovation in designing solutions tailored to specific industrial needs.

When calculating the specific weight of a steel bar grating, professionals often refer to manufacturer’s specification sheets or use established formulas that consider these variables. The weight is usually expressed in pounds per square foot (PSF) or kilograms per square meter (KGM), providing a standardized measure for comparison and selection. Accurate weight estimation not only influences the design but also affects the transportation and installation processes. Heavy gratings may require specialized equipment for lifting and installation, thereby impacting the overall project timeline and costs. Therefore, an adept understanding of the interactions between material choice, dimensions, and spacing can facilitate more informed decision-making to enhance project efficiency. In conclusion, the weight of steel bar grating is a core consideration that impacts the functionality and economics of a project. Industry professionals must engage with manufacturers and leverage technical specifications to select the most suitable grating type. By doing so, they ensure that their projects benefit from optimally balanced weight, strength, and durability, thereby achieving both structural and economic goals. This comprehensive approach not only facilitates compliance with safety standards but also fosters innovation in designing solutions tailored to specific industrial needs.

Share

Prev:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025