- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

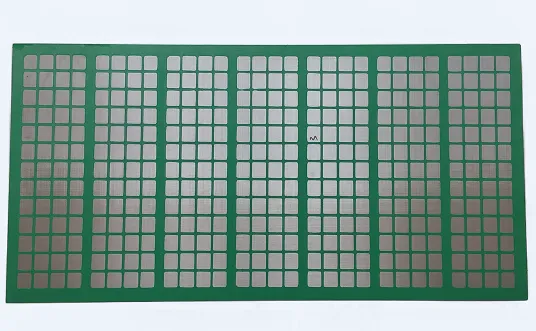

Durable Steel Grating Panels for Enhanced Safety and Performance in Various Applications

Understanding Steel Grating Panels Applications and Advantages

Steel grating panels have emerged as a fundamental component in various industrial applications, owing to their strength, durability, and versatility. These panels are created by welding or forging steel cross bars to form a series of openings, producing a grid-like structure that allows for effective drainage, ventilation, and safety. This article delves into the key features, benefits, and applications of steel grating panels.

Composition and Types

Steel grating panels are typically made from carbon steel, stainless steel, or alloy steel, depending on the required strength and environmental conditions. The most common types include

1. Bar Grating Comprises parallel steel bars spaced equally apart. It is widely used for flooring systems and walkways. 2. Expanded Metal Grating Created from a single sheet of metal that has been slit and stretched to form a mesh pattern. This type offers greater airflow and is useful for security applications. 3. Perforated Grating Features holes punched into a flat sheet of metal, providing both strength and the ability for fluids or air to pass through.

Key Advantages

The advantages of steel grating panels make them a popular choice in several sectors

1. Strength and Load-Bearing Capacity Steel grating panels are renowned for their high strength-to-weight ratio. They can accommodate heavy loads while remaining lightweight, making them suitable for parking garages, heavy equipment areas, and industrial flooring.

2. Durability When properly maintained, steel grating panels resist deformation, corrosion, and wear. Galvanized finishes further enhance their lifespan, making them ideal for outdoor applications exposed to harsh elements.

steel grating panels

3. Safety The open design of steel grating panels facilitates excellent drainage and minimizes the risk of slip-and-fall accidents in wet or greasy environments. They provide secure footing for workers while allowing contaminants to flow away.

4. Versatility These panels can be custom-designed to fit various applications, including walkways, platforms, stair treads, and drainage covers. Their adaptability makes them ideal for industries ranging from construction to food processing.

5. Cost-Effectiveness While the initial investment in steel grating panels might be higher than other materials, their long life, low maintenance needs, and quick installation often result in overall cost savings.

Applications

Steel grating panels find utility in a broad spectrum of industries

- Manufacturing and Warehousing Used for flooring, walkways, and work platforms to enhance safety and efficiency. - Oil and Gas Employed on offshore platforms and chemical plants for walking surfaces and drainage. - Transportation Utilized in airports and train stations for grating over drainage systems and platforms. - Infrastructure Common in bridges, pathways, and public areas to facilitate pedestrian access while enabling water run-off.

Conclusion

In conclusion, steel grating panels play an essential role in modern infrastructure, providing safety, durability, and functionality across various applications. Their ability to withstand heavy loads and environmental challenges makes them an invaluable asset in both industrial and commercial settings. As industries continue to evolve and prioritize safety and efficiency, the demand for reliable materials like steel grating panels is sure to grow, solidifying their place in the construction and manufacturing sectors for years to come.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025