- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

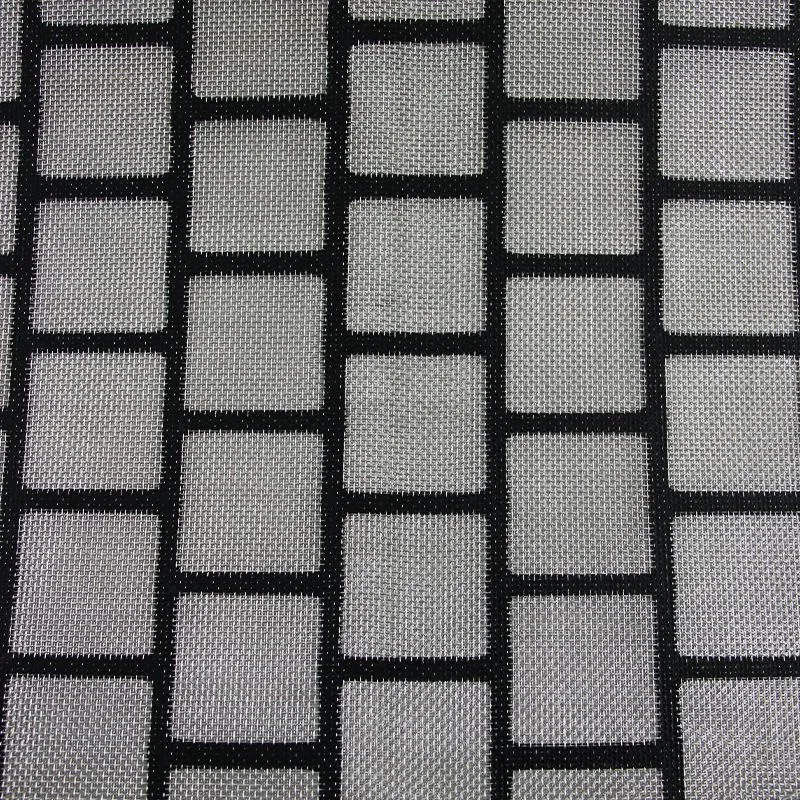

Innovative Bar Grating Solutions for Versatile Platform Applications and Enhanced Durability

The Versatility of Bar Grating Platforms

Bar grating platforms have gained increasing popularity in various industries due to their outstanding structural integrity, versatility, and ease of maintenance. These platforms are typically made from materials such as steel, aluminum, or fiberglass, providing a durable and reliable surface suitable for numerous applications.

One of the primary advantages of bar grating platforms is their ability to provide a high level of safety and stability. The design features interlocking bars that create a mesh-like surface, which allows for efficient drainage and reduces the accumulation of water and debris. This is particularly important in environments where slips and falls could pose significant hazards. For instance, in industrial settings, the drainage capabilities of bar grating help maintain dry surfaces, significantly lowering the risk of accidents.

Moreover, bar grating platforms are incredibly versatile. They can be used in various fields, including construction, manufacturing, transportation, and environmental sectors. In manufacturing plants, bar grating is often employed for walkways, platforms, and stair treads because it allows personnel to navigate safely while supporting heavy equipment. In transportation, these platforms are used in loading docks and bridges to ensure safe and efficient operations.

bar grating platform

In environmental applications, bar grating is extensively used in wastewater treatment plants and chemical processing facilities

. Its ability to withstand harsh chemicals and extreme weather conditions makes it an ideal choice for applications where durability is crucial. Additionally, bar grating platforms can be custom-designed to meet specific requirements, including varying load capacities and sizes, which enhances their utility in specialized environments.Another significant benefit of bar grating platforms is their cost-effectiveness. Compared to solid surfaces, the open design of bar grating requires less material, which can lead to lower production costs. Furthermore, the lightweight nature of bar grating makes installation and transportation easier, reducing labor costs and time.

Maintenance of bar grating platforms is also straightforward. The open structure allows for easy cleaning, ensuring that any buildup of debris or contaminants can be swiftly dealt with. This aspect is particularly essential in environments where hygiene and safety are paramount, such as food processing plants and hospitals.

In conclusion, bar grating platforms represent an essential component in many industrial and environmental applications due to their safety features, versatility, cost-effectiveness, and ease of maintenance. As industries continue to evolve, the demand for efficient and reliable solutions will undoubtedly ensure that bar grating remains a popular choice for construction and design professionals alike. Investing in bar grating platforms is not just a practical decision but a step towards enhancing operational safety and efficiency across various sectors.

-

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025