- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Understanding Shaker Screen Mesh Options for Effective Filtration and Separation Techniques

Understanding Shaker Screen Mesh An Essential Element in Drilling Operations

In the world of drilling operations, the efficiency and effectiveness of the process are largely determined by the choice of equipment and materials used. One of the critical components that facilitate these processes is the shaker screen mesh. Understanding its significance, types, and applications can help ensure optimal performance in various drilling environments.

What is a Shaker Screen Mesh?

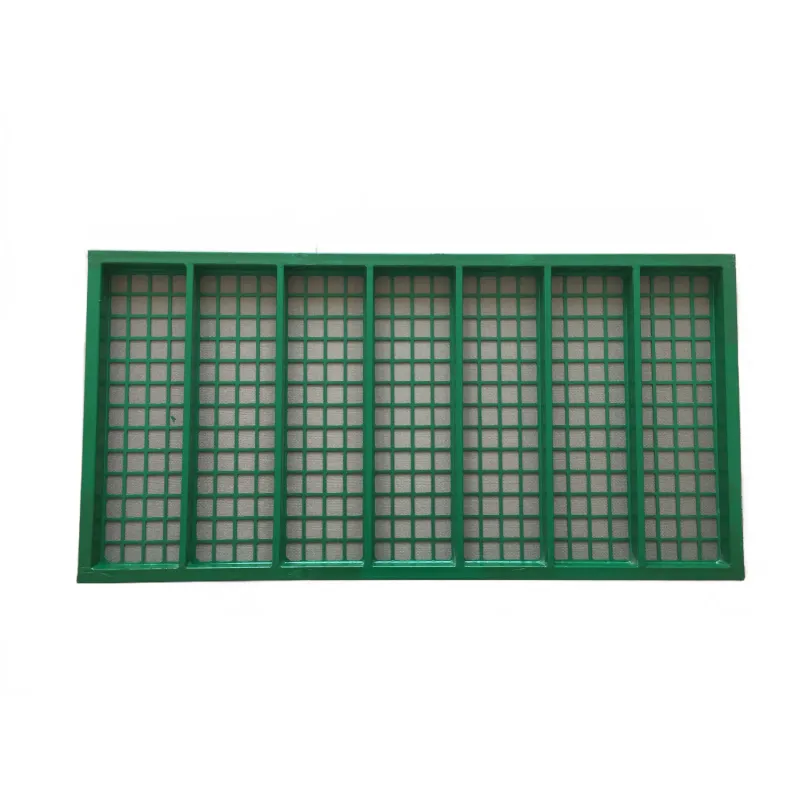

Shaker screen mesh is a vital component of a shale shaker, a device used in oil and gas drilling to separate solids from liquids. The shaker typically operates as part of a larger drilling fluid system, helping to manage the drilling mud's viscosity and density. The mesh functions as a barrier, allowing only the desired size of particles to pass through, thus preventing larger solids from contaminating the drilling fluid.

The mesh is typically made from steel or composite materials and is designed with precision-cut holes that can vary in size. These holes are crucial in determining the efficiency of the shaker. A properly selected mesh type ensures that the drilling fluid remains clean, thereby enhancing the drilling process.

Types of Shaker Screen Mesh

There are several different types of shaker screen meshes available, tailored for specific applications

1. Wire Mesh Screens These are made from woven wire strands and are generally durable and effective in separating solids of varying sizes. They come in different weaves, such as plain and twilled, providing options for customization based on specific drilling needs.

2. Composite Screens Combining a mesh layer with a backing layer, composite screens offer enhanced durability and weight savings. They are often used in more advanced drilling operations due to their ability to handle higher volumes of cuttings.

shaker screen mesh

3. Plastic Screens Lightweight and resistant to corrosion, plastic screens are ideal for certain applications where traditional metal screens may not perform effectively. These are typically employed for specific oil and gas tasks or in environments where chemical resistance is crucial.

The choice of shaker screen mesh depends on various factors, including the size of the particles being filtered, the viscosity of the drilling fluid, and the overall drilling environment.

Applications and Importance

Shaker screen mesh plays a pivotal role in multiple sectors beyond drilling, including

- Mining In mineral extraction, shaker screens are used to separate valuable materials from undesirable ones, enhancing the efficiency of the mining process.

- Environmental Shaker screens are also utilized in the treatment of wastewater and the recycling of aggregates in construction, contributing to environmental sustainability efforts.

The effectiveness of shaker screen mesh directly impacts drilling efficiency. A well-implemented mesh solution minimizes downtime, reduces the need for excessive cleaning, and ultimately lowers operational costs. Poor filtration can lead to increased wear on drilling equipment and the potential for more frequent maintenance, resulting in delays and economic consequences for drilling companies.

Conclusion

In conclusion, shaker screen mesh is a critical component in the oil and gas industry, as well as in mining and environmental applications. The variety of mesh types allows for tailored solutions to meet specific drilling needs, ensuring efficient solid-liquid separation. By investing in the right shaker screen mesh, operators can improve drilling performance, reduce operational costs, and enhance the overall effectiveness of the drilling processes. As technology continues to advance, the development of newer and more effective shaker screen solutions will remain an ongoing trend, driving the future of efficient drilling operations. Understanding the nuances of shaker screen mesh is essential for professionals looking to optimize their drilling activities and achieve successful outcomes in their projects.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025