- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

shaker screen manufacturers

The Importance of Shaker Screens in the Oil and Gas Industry

Shaker screens play a vital role in the oil and gas industry, particularly in the drilling process. These screens are used to separate solid materials from drilling fluids, thereby ensuring the efficiency and effectiveness of the drilling operation. With the ever-increasing demand for oil and gas, the significance of shaker screens and their manufacturers has never been more critical. This article explores the types of shaker screens, the manufacturing process, and the leading manufacturers in the market.

Understanding Shaker Screens

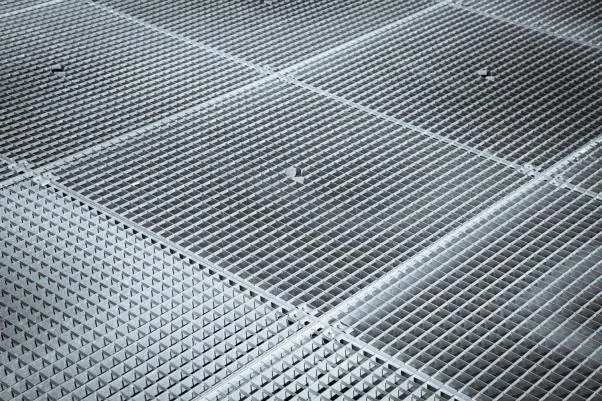

Shaker screens are essential components of drilling fluid management systems. They are typically made of woven wire cloth or perforated plates and are mounted on a vibrating shaker. The primary function of a shaker screen is to filter out drill cuttings from the drilling mud, allowing only the fluid to pass through. This process helps maintain the consistency and viscosity of the drilling mud, which is crucial for efficient drilling operation.

There are various types of shaker screens, including flat panels, pyramid screens, and composite screens. Flat panel screens are commonly used for their simplicity and effectiveness. Pyramid screens, on the other hand, offer a higher surface area for filtration, making them suitable for more demanding applications. Composite screens combine the best features of both wire cloth and synthetic materials, offering durability and performance in challenging environments.

The Manufacturing Process

The manufacturing of shaker screens involves several stages, including material selection, weaving or perforating, and quality control. High-quality materials are essential to ensure the screens can withstand the harsh conditions of drilling environments. For wire cloth screens, manufacturers often use stainless steel or other durable metals that can resist corrosion and wear.

Once the materials are selected, the weaving or perforating process begins. For wire cloth screens, the wires are woven into different patterns to achieve the desired mesh size and strength. Perforated screens are created by punching holes into metal sheets to create the required size and pattern. Both processes are highly specialized and require precision to ensure the screens meet industry standards.

Quality control is a critical aspect of the manufacturing process. Manufacturers must test the screens for durability, tensile strength, and filtration efficiency to ensure they can perform effectively in real-world conditions. Rigorous testing also helps identify any defects or weaknesses in the screens, reducing the risk of failure during drilling operations.

shaker screen manufacturers

Leading Shaker Screen Manufacturers

There are several prominent manufacturers in the shaker screen industry, each offering various products tailored to specific applications. Some of the leading names include

1. Schlumberger A global leader in oilfield services, Schlumberger offers a range of shaker screens designed for various drilling applications. Their screens are known for their high quality and performance.

2. Halliburton Another major player in the oil and gas industry, Halliburton manufacturers a variety of shaker screens, including composite and wire cloth options. They focus on innovative solutions to improve drilling efficiency.

3. Brandt Known for their commitment to quality and customer satisfaction, Brandt produces a range of shaker screens that have been optimized for different drilling environments.

4. Baker Hughes This company offers a wide selection of shaker screens, emphasizing both performance and durability. Their products are designed to withstand the demands of modern drilling operations.

5. Sepor As a manufacturer of industrial equipment, Sepor also produces shaker screens with a focus on high-quality materials and innovative designs.

Conclusion

Shaker screens are integral to successful drilling operations in the oil and gas industry. With various types available, understanding their applications and the importance of quality manufacturing is crucial for operators. As the industry continues to evolve, the role of shaker screen manufacturers will remain essential in ensuring efficient and effective drilling processes. Investing in high-quality shaker screens can lead to significant improvements in drilling performance and cost-effectiveness, making the choice of manufacturer a key factor in operational success.

-

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025