- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

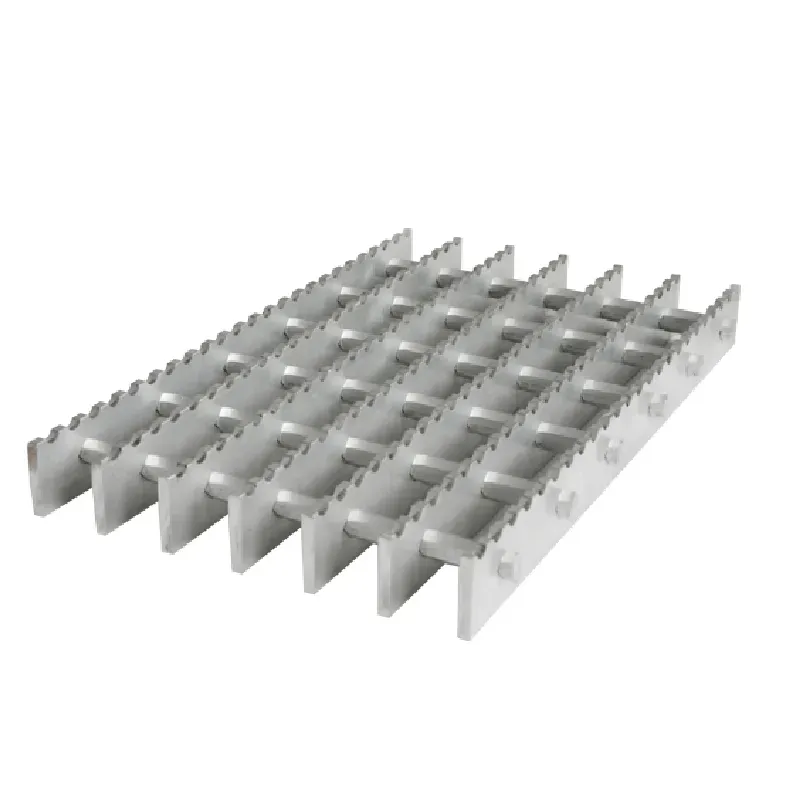

Durable Heavy-Duty Bar Grates Metal for Floors & Walkways Industrial Strength

- Defining bar grates metal

fundamentals and applications - Technical advantages and material properties explained

- Performance data analysis through comparative metrics

- Manufacturer comparison for industrial buyers

- Custom engineering solutions for specialized projects

- Application case studies across industries

- Implementation considerations and safety standards

(bar grates metal)

Bar Grates Metal: Engineered Solutions for Demanding Environments

Industrial flooring demands precision engineering where bar grates metal systems provide critical infrastructure support. These open-grid assemblies combine load-bearing capacity with environmental management capabilities essential for manufacturing plants, wastewater facilities, and transportation hubs. The fundamental architecture interconnects load bars and cross rods through resistance welding, creating rigid platforms that withstand extreme conditions. Architects increasingly specify metal walking grates for pedestrian zones requiring slip resistance and chemical resilience. Beyond standard configurations, heavy duty metal floor grates solve unique structural challenges in power generation and maritime settings where corrosion exposure eliminates conventional materials.

Technical Superiority in Industrial Grating Systems

Material composition determines performance benchmarks in metal grating applications. Carbon steel variants rated for 250 MPa yield strength typically serve general industrial purposes, while galvanized coatings extend service life to 25+ years in moderate corrosion environments. For chemical processing facilities, 316L stainless steel demonstrates 0.08mm/year corrosion rates in pH 1-12 exposure. Load distribution capabilities separate category leaders - properly engineered bar grates metal achieve 5,000 lb/ft² static loads through cross-rod integration. Fire resistance remains paramount, with steel gratings maintaining structural integrity at 1000°F when coated with intumescent sealants. Thermal expansion coefficients require precise calculations, as standard carbon grating expands 6.7mm per 10-meter span during 100°C temperature fluctuations.

Performance Metrics Through Comparative Testing

Laboratory validation separates marketing claims from engineering reality. Standardized ISO 14122 testing reveals significant performance variations:

| Performance Metric | Entry-Level | Mid-Grade | Heavy Duty Metal |

|---|---|---|---|

| Deflection at 150% Load | 9.8mm | 5.2mm | 2.1mm |

| Slip Resistance (DIN 51130) | R9 Rating | R11 Rating | R13 Rating |

| Corrosion Cycles (ASTM B117) | 500 hours | 1,000 hours | 2,000+ hours |

| Fatigue Strength Cycles | 1 million | 2 million | 5 million+ |

| Impact Resistance (Joules) | 45 J | 80 J | 140 J |

Industry Leader Capability Assessment

Procurement decisions require evaluating manufacturer specialties across technical dimensions. Market leaders offer significant advantages in specialized applications:

| Supplier | Max Span (m) | Custom Fabrication | Specialized Alloys | Delivery Lead Time |

|---|---|---|---|---|

| Standard Industrial | 3.2 | Limited | Carbon Steel | 4 weeks |

| Midwest Grating Co. | 4.8 | Moderate | Stainless Grades | 5 weeks |

| Heavy Duty Solutions Inc. | 6.4 | Full Service | Duplex/Marine | 6 weeks |

| Marine & Offshore Grating | 8.2 | Special Projects | Super Duplex | 8 weeks |

Engineered Customization for Complex Requirements

Beyond standard sizes, advanced fabricators develop application-specific configurations through:

- Non-standard bearing bar arrangements: Variable spacing from 15/16" to 6" centerlines

- Compound curvature forming: Radii adaptations for structural integration

- Alloy hybridization: Carbon steel frames with stainless load surfaces

- Access integration: Hinged sections for below-deck maintenance

- Enhanced drainage: 15-40% open area adjustments

The Philadelphia refinery project exemplified customized engineering, where titanium-nickel alloy metal walking grates resisted 98°C sulfuric acid exposure while supporting 18-ton chemical reactors. Fabrication required 0.08mm tolerance precision across 112 irregular sections totaling 12,000 ft².

Documented Performance Across Industrial Sectors

Real-world installations validate engineering specifications across critical environments:

- Wastewater Treatment: Duplex stainless installations at Detroit Metro Plant show 0.003mm/year corrosion after 7 years of continuous H₂S exposure

- Power Generation: Turbine deck platforms at Georgia Power Facility withstand 115dB vibrations for 80,000 operational hours

- Marine Terminals: 316L heavy duty metal floor grates at Long Beach Port show zero fatigue cracks after 17 million forklift passes

- Food Processing: USDA-compliant grating systems reduce sanitation labor by 35% at Tyson poultry plants

Implementing Compliant Metal Walking Grates

Proper installation requires addressing structural dynamics often overlooked in specification. The ANSI/NAAMM MBG 531 standard mandates 1:200 deflection limitations under full load, necessitating professional span calculations, particularly for cantilevered sections. Barrier requirements per IBC Section 1012 include 42" minimum height with intermediate rails when adjacent to elevation changes exceeding 30". Slip resistance ratings must correspond to environmental conditions - R10 classifications suffice for interior stairs, while offshore platforms demand R13 surfaces. Fire egress considerations involve maintaining clear 36" pathways meeting NFPA 101 illumination requirements. During the Denver Airport expansion, installation precision ensured 0.18° pitch consistency across 14,000 ft² of interconnected metal walking grates for seamless drainage.

(bar grates metal)

FAQS on bar grates metal

Q: What are the primary applications of bar grates metal?

A: Bar grates metal are commonly used in industrial settings, walkways, and drainage systems to provide secure footing and efficient water runoff. They enhance safety with their sturdy design and prevent slips.Q: What advantages do metal walking grates offer for outdoor use?

A: Metal walking grates deliver excellent durability, corrosion resistance, and high load-bearing capacity. They ensure long-lasting performance in harsh environments like docks or construction sites.Q: How sturdy are heavy duty metal floor grates for supporting heavy equipment?

A: Heavy duty metal floor grates are designed to handle intense weights, such as machinery or vehicles. Their reinforced construction ensures reliable support while maintaining safety standards.Q: Where are bar grates metal typically installed in commercial buildings?

A: They are installed in areas like stair treads, mezzanines, and entranceways. This placement optimizes safety and drainage while providing a robust surface for foot traffic.Q: What maintenance tips apply to metal walking grates?

A: Regularly clean them with mild detergent and water to remove debris. Inspect for corrosion and apply protective coatings as needed to extend their lifespan.-

The Role of Shale Shaker ScreensNewsJun.11,2025

-

Steel Grating Remains a Superior ChoiceNewsJun.11,2025

-

Does Safety Net Mean in the Modern Construction WorldNewsJun.11,2025

-

Concrete Weight Coating in Offshore Pipeline StabilityNewsJun.11,2025

-

Choosing the Right Steel Grating CompanyNewsJun.11,2025

-

Best Shale Shaker Screen for SaleNewsJun.11,2025