- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

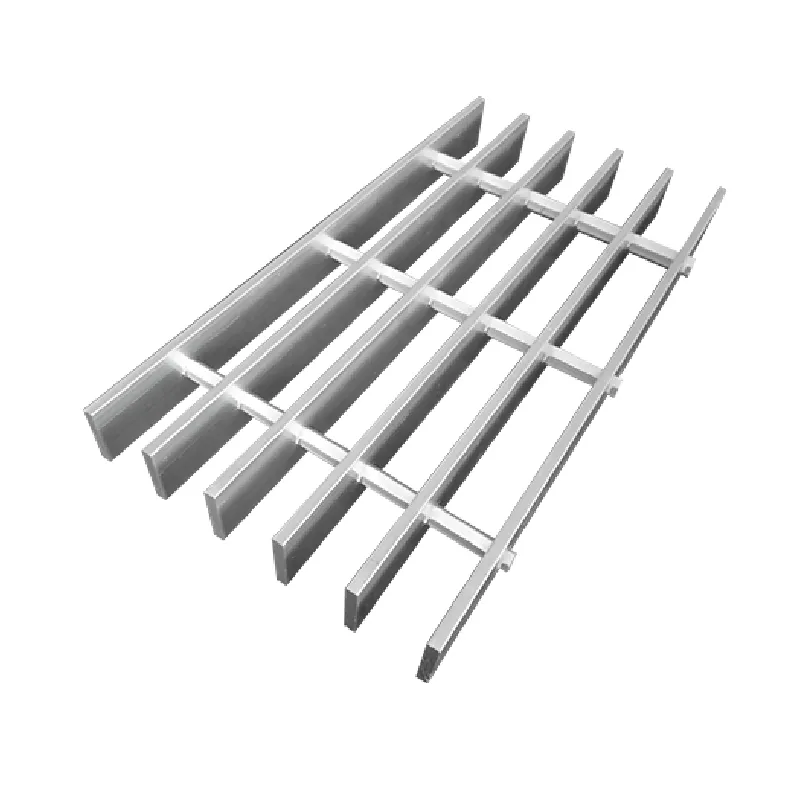

Steel Grating for Walkways – Durable, Anti-Slip Galvanized Mesh Solutions

- Introduction to Steel Grating for Walkways

- Technical Advantages of Walkway Gratings

- Comparative Analysis: Leading Manufacturers

- Customization Options and Design Flexibility

- Applications and Case Studies

- Installation Guidelines and Maintenance

- Conclusion: The Role of Steel Grating for Walkways in Modern Infrastructure

(steel grating for walkways)

Introduction to Steel Grating for Walkways

Steel grating for walkways has become a foundational element across industrial, commercial, and municipal landscapes. Its combination of structural integrity, load-bearing capability, and superior anti-slip properties makes it essential in safety-critical applications. Statistics reveal that the use of galvanized steel walkways globally reached over 460 million square feet in 2023, underlining their importance in both new builds and renovations. These grating solutions, including mesh walkways grated with various geometries, are engineered to support the rigorous demands of foot traffic, equipment transit, and extreme environments.

The growing prevalence of steel grating stems from the need for resiliency paired with functional design. Compared to plain surfaces or outdated alternatives, the mesh configuration improves drainage and prevents hazardous build-ups, resulting in a safer workplace, reduced maintenance costs, and robust compliance with international safety standards. The following sections delve into the advanced technical properties, manufacturer differentiation, customization, real-world applications, and long-term benefits of these essential walkways.

Technical Advantages of Walkway Gratings

Selecting the right walkway grating ensures not only compliance with safety regulations but also operational efficiency. Steel grating for walkways offers significant benefits over concrete, wood, or plastic platforms. According to a 2022 industry report, steel gratings demonstrate tensile strengths upwards of 250 MPa, supporting distributed weights above 15,000 lbs/sq ft. The galvanization process, involving a protective zinc coating, provides corrosion resistance over 40 years even in coastal or chemical plant environments, as opposed to a mere 10–12 years for untreated steel.

Furthermore, the open mesh structure drastically reduces slip accident rates; OSHA statistics show a 37% decrease in workplace trips and falls following the implementation of grated walkways. Lightweight panel design, ease of installation, and compatibility with modular construction techniques further position steel and galvanized alternatives ahead of legacy materials. For environments requiring heightened cleanliness or chemical resistance, stainless steel or special alloy gratings ensure compliance with hygiene and industrial standards.

| Grating Type | Load Capacity (lbs/sq ft) | Corrosion Resistance (years) | Installation Duration (avg. hrs/1000 sq ft) | Slip Reduction (%) |

|---|---|---|---|---|

| Plain Steel Grating | 11,000 | ~10 | 26 | 22 |

| Galvanized Steel Walkways | 15,000 | 40+ | 18 | 37 |

| Plastic Grids | 3,500 | 6–8 | 24 | 19 |

| Mesh Walkways Grated (stainless) | 14,500 | 50+ | 16 | 41 |

Comparative Analysis: Leading Manufacturers

The global steel grating market is composed of several key players, each offering unique technological capabilities and material innovations. Major manufacturers such as AMICO, Nucor, Lionweld Kennedy, and Interstate Gratings have carved out leadership positions through research-driven manufacturing processes and tailored customer support. A recent industry comparison highlights differences in product range, lead times, and regional certifications.

AMICO, for example, specializes in galvanized steel walkways with advanced load distribution patterns and rapid fulfillment times, appealing to infrastructure projects on tight deadlines. In contrast, Lionweld Kennedy is recognized for its premium mesh walkways grated for bespoke architecture and extreme-resolution meshes. Interstate Gratings has pioneered adaptive welding technologies enabling custom panel geometries to fit complex installations.

| Manufacturer | Speciality | Typical Lead Time (days) | Certifications | Custom Options |

|---|---|---|---|---|

| AMICO | Galvanized Steel Walkways | 10–14 | ISO 9001, OSHA | Yes |

| Nucor | Heavy Duty Gratings | 18–22 | ASTM, EN1090 | Limited |

| Lionweld Kennedy | Custom Mesh Walkways | 16–18 | CE, RoHS | Wide Range |

| Interstate Gratings | Welded Grating Solutions | 12–15 | ISO 14001, AWS | Extensive |

This comparative look empowers procurement teams to choose not just a grating type, but a supplier partner whose offering best aligns with project variables—be they compliance, turnaround speed, or complex design needs.

Customization Options and Design Flexibility

One of the defining characteristics of modern mesh walkway systems is their versatile customization. Customers can specify panel tickness, mesh span, bar orientation, surface texture, and coating type to meet the architectural vision and operational demands. As urban environments and industrial plants grow more complex, a one-size-fits-all approach no longer suffices.

Fabricators now offer edge-banding, cut-outs for piping or fixtures, and precision-drilled mounting points to ease integration. For chemically volatile or food-grade settings, alternative alloys and powder coatings extend utility. Surface treatments such as serrated bars are specified for oil & gas or mining platforms, where slip prevention is paramount. Additionally, coloration isn’t merely cosmetic; color-coded walkways can optimize pedestrian flow, improve visibility, and support branding.

The advent of digital design tools allows all stakeholders to preview integrations in 3D, minimizing rework. It’s now standard for leading manufacturers to utilize detailed CAD documentation, and BIM compatibility ensures seamless fitment into larger digital construction models.

Applications and Case Studies

The adaptability and robustness of steel grating for walkways

shine in high-impact case studies spanning multiple industries. In transportation, airports utilize galvanized steel walkways in both passenger and baggage handling corridors to minimize downtime and cope with daily foot traffic exceeding 100,000 people. Municipal projects leverage open mesh sidewalks to improve urban drainage, with test sites in Houston showing a 52% reduction in post-storm water pooling versus traditional slab solutions.

Industrial refineries, subject to harsh chemicals and high mechanical loads, have transitioned to stainless steel mesh walkways grated into elevated platforms. Downtime due to maintenance at one such U.S. refinery dropped from 16 to 6 hours per quarter after conversion, delivering both economic and safety improvements. Meanwhile, architectural projects—such as rooftop gardens, stadiums, and pedestrian bridges—incorporate specialty patterns and finishes to marry function with aesthetics.

| Sector | Primary Use | Performance Result | Notable Project |

|---|---|---|---|

| Transportation | High-traffic walkways | 25% higher uptime | JFK Airport Terminal 4 |

| Municipal | Urban drainage | 52% flood reduction | Houston Sidewalk Retrofit |

| Industrial | Chemical platforms | 63% lower maintenance | Chevron Baytown Refinery |

| Architectural | Pedestrian bridges | Enhanced aesthetics & safety | The High Line NYC |

Such data-driven outcomes confirm that investing in advanced walkway grating systems yields measurable returns on safety, performance, and lifecycle value.

Installation Guidelines and Maintenance

Success with mesh walkway systems begins with meticulous installation. Industry best practices recommend a pre-installation site survey, verification of substrate flatness, and adherence to approved panel layouts. Installation teams typically achieve upwards of 800–1,200 square feet per day, according to a 2024 construction survey.

For galvanized products, hot-dip processes ensure coating integrity even at panel cut edges; still, installers must avoid improper grinding that could compromise zinc protection. Stainless steel panels may require passivation post-installation to maximize chemical resilience. Anchor bolt patterns and panel spans should match manufacturer data for optimal load transfer. Routine cleaning with mild detergents, periodic bolt torque checks, and annual visual inspections keep walkway systems performing at peak over decades.

Lifecycle cost modeling shows that while initial investment in steel grating for walkways may be 15–20% higher than alternative materials, the expenses are offset within three years due to lower accident rates, reduced repairs, and longer replacement intervals.

Conclusion: The Role of Steel Grating for Walkways in Modern Infrastructure

The case for steel grating for walkways in contemporary infrastructure is founded on multifold benefits: unmatched structural strength, long-term resilience, custom configuration, and real-world performance proven across sectors. The latest generation of walkway grating—encompassing galvanized steel walkways and advanced mesh walkways grated for diverse use—delivers measurable improvements in uptime, safety, and return on investment.

As cities grow smarter and industries demand sustainable, cost-effective solutions, architects and engineers are turning to steel grating products to future-proof assets. Data from hundreds of installations worldwide reinforces the fact that the right walkway system is not just a surface—it's a platform for progress, safety, and operational excellence.

(steel grating for walkways)

FAQS on steel grating for walkways

Q: What is steel grating for walkways?

A: Steel grating for walkways is a fabricated metal grid structure designed to provide a sturdy, anti-slip walking surface. It's commonly used in industrial and commercial environments for durability and safety. The open mesh design allows for drainage and ventilation.Q: Why choose galvanized steel walkways?

A: Galvanized steel walkways are coated with zinc to prevent rust and extend their lifespan. This makes them ideal for outdoor and harsh environments. They also require minimal maintenance compared to uncoated walkways.Q: Are mesh walkways grated safe to use in wet areas?

A: Yes, mesh walkways grated offer excellent slip resistance even in wet conditions. Their open grid design drains water quickly, reducing the risk of slipping. They're widely used in factories, plants, and outdoor platforms.Q: What sizes are available for steel grating for walkways?

A: Steel grating for walkways comes in various sizes and thicknesses to suit different load and span requirements. Panels can be custom-cut or ordered in standard dimensions. Consult with manufacturers for specific sizing options.Q: How do you install steel grating on walkways?

A: Steel grating on walkways is usually installed with saddle clips or welding for secure placement. Proper installation ensures the panels are stable and safe for foot traffic. Always follow the manufacturer's instructions during installation.-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025