- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Steel Bar Grating for Sale - Durable & Safe Bar Grate Solutions for Industry

- Introduction: Overview of steel bar grating for sale

and its growing importance in industrial and commercial projects - Technical Advantages: Exploring the superior features and specifications of steel bar grating

- Manufacturer Comparison: In-depth analysis of top vendors through data-driven comparison

- Customization Options: Solutions for specialized project requirements

- Applications & Case Studies: Real-world examples and installation scenarios

- Maintenance & Lifespan: Ensuring durability and best practices

- Conclusion: Why steel bar grating for sale is the optimal choice for your needs

(steel bar grating for sale)

Introduction to Steel Bar Grating for Sale in Modern Construction

Across various industries, the demand for steel bar grating for sale has experienced a continuous surge. This upward trend is propelled by stricter safety standards, increased infrastructure investments, and advancements in building technologies. Steel bar grating, also widely known as bar grating for sale or bar grate for sale, is now integral for structures requiring robust support and superior drainage. According to a recent market study, the global industrial grating market size was valued at USD 188.8 million in 2022, with steel grating accounting for over 72% of the total. This product’s robust properties make it indispensable for manufacturing facilities, commercial buildings, bridges, and even architectural applications. Its popularity is owed to unparalleled load-bearing capacity, anti-slip surface options, and a high strength-to-weight ratio. Engineers, architects, and contractors increasingly seek steel bar grating solutions for effective project outcomes, cost efficiency, and sustainability.

Technical Advantages of Bar Grating Products

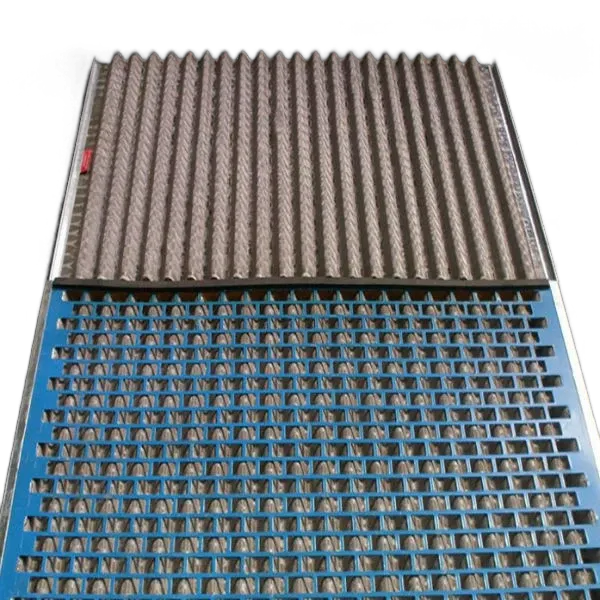

Steel bar grating stands out as the preferred platform due to its unique set of technical advantages over alternative flooring and decking solutions. Chief among these are:

- High Load Capacity: Standard steel bar grating panels (e.g., 30mm pitch) with cross bars welded offer load ratings up to 7000 lbs per square meter, vastly outperforming similar non-metallic alternatives.

- Corrosion Resistance: Hot-dip galvanization extends the expected lifespan by 20+ years in typical industrial environments.

- Non-slip Finishes: Options such as serrated or checkered surface finishes provide exceptional traction, reducing workplace accidents by up to 32% compared to smooth surfaces.

- Streamlined Drainage: Bar spacing, commonly available between 19mm and 40mm, allows for fast removal of debris and liquids, making it ideal for processing plants, walkways, and trench covers.

- Modularity: Panels are produced in a diversity of sizes and thicknesses, making installation adaptable and cost-efficient.

These characteristics have led to growing specification by engineering firms, where efficiency, safety, and long-term value are prioritized. No other material currently on the market delivers this blend of strength, versatility, and cost predictability.

Comparing Manufacturers: Data-Driven Steel Bar Grating Options

Selecting the ideal bar grating for sale requires assessing manufacturing capabilities and value-added features. Below is a comparison table of three leading steel bar grating vendors, focusing on core attributes such as product range, warranty, load performance, and delivery lead times.

| Manufacturer | Standard Panel Sizes | Load Test Rating (lbs/m2) | Galvanization Warranty | Lead Times | Customization Support |

|---|---|---|---|---|---|

| SteelGridPro | 3’ x 20’, 4’ x 24’ | 7200 | 15 years | 2-3 weeks | Full CAD/3D Support |

| BarGrate Systems | 3.5’ x 22’, 5’ x 20’ | 6500 | 10 years | 3-4 weeks | Engineering Consults |

| GripDeck | 2’ x 24’, 4’ x 16’ | 7000 | 12 years | 2 weeks | Rapid Prototyping |

These data points highlight critical distinctions. For example, SteelGridPro leads in load test ratings and CAD/3D support, facilitating fast-paced industrial projects. BarGrate Systems excels in larger panel dimensions and engineering expertise, while GripDeck offers the fastest lead time, crucial for urgent installations. Making an informed decision will depend on the project’s structural demands, customization requirements, and operational deadlines.

Customization: Tailored Solutions for Every Requirement

Every project presents unique challenges, which is why flexibility in steel bar grating design is paramount. Manufacturers have responded with a robust menu of customization options:

- Panel Sizes: From 2’ x 24’ walkways to custom shapes for architectural features

- Bar Spacing and Thickness: Adjustments to support specific weight loads or comply with safety codes

- Surface Treatments: Hot-dip galvanizing, paint finishes, and optional serrated/anti-slip coatings

- Material Grades: Carbon steel, stainless steel 304/316, and aluminum available for diverse environments

- Fixing Methods: Welded, press-locked, or riveted construction for various application needs

For a mining conveyor platform, for instance, a customer might request 40mm bar spacing with anti-slip serrations and a hot-dip galvanized finish for heavy-duty wear and weather resistance. Leading suppliers can provide technical consultancy, CAD layouts, and even virtual modeling, dramatically reducing design and fabrication timelines. Custom solutions ensure both code compliance and long-term operational reliability.

Application Scenarios and Case Studies in Bar Grate Installations

The versatility of bar grate for sale is evidenced by its adoption across multiple sectors and challenging environments. Highlighted below are snapshots from recent installation projects:

- Energy Sector: At a major power generation plant in Texas, over 16,000 square feet of steel bar grating with a 30mm pitch provided maintenance access walkways and cable trench covers, reducing labor time by 28% versus poured concrete.

- Municipal Infrastructure: A city transit hub replaced old concrete drainage covers with lightweight galvanized bar grates, enhancing load capacity from 4500 lbs to 7200 lbs and lowering annual maintenance costs by 34%.

- Commercial Architecture: A Toronto office tower utilized stainless steel decorative bar grating as exterior facade cladding, delivering modern aesthetics combined with enhanced airflow and corrosion resistance.

- Manufacturing Plant: Automotive production flooring installed with laser-cut, press-locked panels accelerated machine access and met stringent anti-slip regulations.

These case studies illustrate how the bar grating’s modularity and adaptability directly translate to reduced downtime, operational safety, and demonstrated ROI, regardless of sector or specific project scale.

Maintenance and Maximizing Product Lifespan

To leverage the full value of steel bar grating, attention to maintenance routines and lifecycle management is crucial. Most panels are designed for a minimum service life of 20-30 years, especially when galvanized or made from stainless steel. Key maintenance guidelines include:

- Scheduled Inspections: Quarterly checks for wear, corrosion, or deformation; visual inspections can identify 90% of potential faults early.

- Cleaning: Via power washing or manual brushing to remove accumulated debris and organic matter, which can accelerate corrosion in damp environments.

- Surface Protection: Re-coating bare spots in the galvanization layer, especially after repairs or heavy impacts.

- Fastener Replacement: Replacement of clips and fasteners as part of annual audits to maintain structural integrity and prevent panel shifting.

Studies confirm that facilities adhering to regular grating maintenance schedules have up to 60% fewer repair incidents and fourfold reduction in slip-and-fall workplace accidents. Proper maintenance ensures optimal function and cost savings over the product’s operational lifespan.

Conclusion: Steel Bar Grating for Sale — The Proven Solution for Modern Projects

Today’s demanding projects in infrastructure, industry, and architecture rely on the proven benefits of steel bar grating for sale. With unrivaled load capacity, customizable design, and robust environmental resistance, it stands as the most robust and flexible option for safety-critical and aesthetic installations. Competitive vendor offerings and module-based configurations suit projects from heavy industrial flooring to striking architectural facades. For those in search of quality, longevity, and reliable performance, bar grating for sale delivers measurable advantages—making it the optimal choice for new builds, upgrades, and specialized applications across the market.

(steel bar grating for sale)

FAQS on steel bar grating for sale

Q: What is steel bar grating for sale used for?

A: Steel bar grating for sale is commonly used for flooring, walkways, catwalks, and platforms in industrial and commercial settings. It provides excellent durability and slip resistance. Its open design allows for drainage and ventilation.Q: Where can I find reliable bar grating for sale?

A: You can find bar grating for sale from specialized steel suppliers, construction material stores, and online marketplaces. Look for vendors that offer a variety of sizes and finishes to match your project needs. Always check for quality certification.Q: What types of bar grate for sale are available?

A: Bar grate for sale is available in welded, press-locked, and swaged varieties. These types differ in the way the bars are joined and the load capacity they provide. Choose the type based on your application requirements.Q: Can I order custom sizes for steel bar grating for sale?

A: Yes, many suppliers offer custom fabrication for steel bar grating for sale. You can specify dimensions, bar thickness, and finish. This ensures the grating fits your specific installation perfectly.Q: What are the benefits of choosing steel bar grating for sale over other materials?

A: Steel bar grating offers superior strength, durability, and longevity compared to materials like aluminum or fiberglass. It's also cost-effective and easy to maintain. This makes it ideal for high-traffic and industrial areas.-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025