- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Mar . 03, 2025 12:27

Back to list

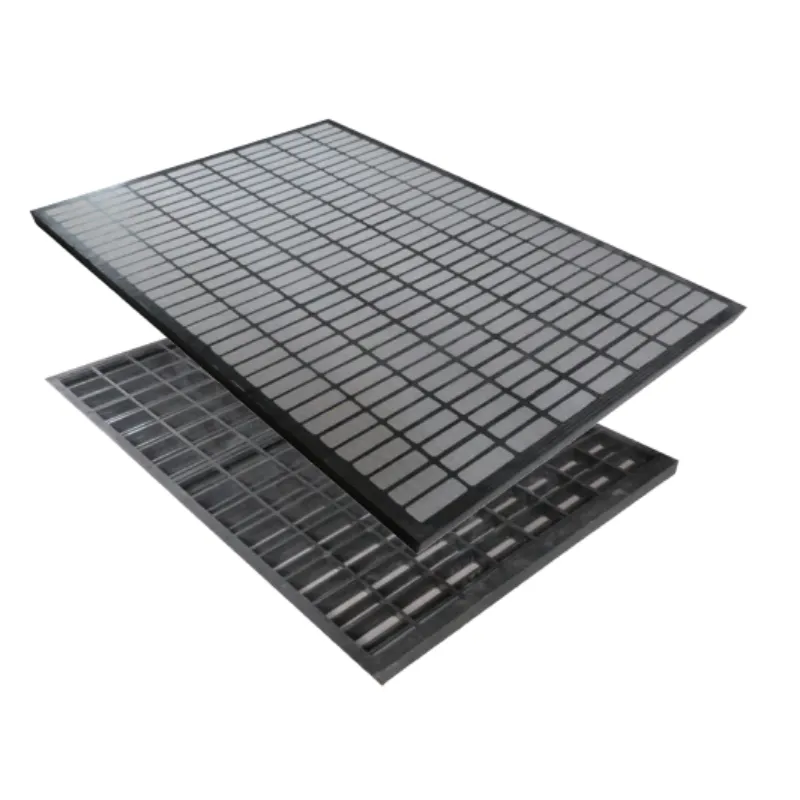

shale shaker screen price

When considering the cost of shale shaker screens, many factors come into play that significantly affects the final purchase decision. Understanding these factors and how they interplay is essential for making an informed buying choice that ensures both financial prudence and operational efficiency. Shale shaker screens are crucial components in the oil and gas drilling industry, where they perform the critical role of removing solids from drilling fluid, subsequently enhancing the quality of the fluid and operational performance.

The location and logistics involved in obtaining shale shaker screens can further influence their prices. Screens sourced from distant manufacturers may entail additional shipping costs, affecting the overall expense. Considering the logistical aspects and opting for local or nearer manufacturers might mitigate these costs, but this involves weighing local offerings against those from established foreign entities renowned for their premium screens. Considering the life cycle cost analysis of shale shaker screens can provide a broader perspective on pricing. While the upfront cost is a crucial factor, potential buyers should also look at the total cost of ownership, which includes maintenance, operational efficiency, and replacement frequency. Screens that may initially seem inexpensive could accrue higher overall costs due to frequent replacements or inefficiencies in operation. Quality assurance and certifications associated with shale shaker screens also impact their pricing structure. Screens endorsed with international quality standards or specific industry certifications may have elevated prices. These certifications serve as a testament to their quality, reliability, and compliance with industry safety and performance standards, thereby building trust and credibility among users. Customer reviews and experiences provide empirical insights into the screen’s performance and value proposition. Exploring user experiences can offer practical understanding regarding the longevity, efficiency, and cost-benefit of different shaker screens, assisting in identifying the best value for money in practical scenarios. Users sharing their firsthand experiences often highlight long-term cost savings achieved through investing in technologically superior screens. In conclusion, the price of shale shaker screens is a composite of multiple interdependent factors, each contributing to its final cost. While striking a balance between cost and quality can be challenging, understanding these elements can facilitate informed purchasing decisions that align with both budgetary and operational necessities. Prioritizing quality, technological advancements, and reputable manufacturers ensures the selection of screens that not only meet immediate financial criteria but also provide long-term operational benefits. Engaging with established brands, staying informed about technological advancements, and considering the total cost of ownership are strategies that underscore expert purchasing in the realm of shale shaker screens.

The location and logistics involved in obtaining shale shaker screens can further influence their prices. Screens sourced from distant manufacturers may entail additional shipping costs, affecting the overall expense. Considering the logistical aspects and opting for local or nearer manufacturers might mitigate these costs, but this involves weighing local offerings against those from established foreign entities renowned for their premium screens. Considering the life cycle cost analysis of shale shaker screens can provide a broader perspective on pricing. While the upfront cost is a crucial factor, potential buyers should also look at the total cost of ownership, which includes maintenance, operational efficiency, and replacement frequency. Screens that may initially seem inexpensive could accrue higher overall costs due to frequent replacements or inefficiencies in operation. Quality assurance and certifications associated with shale shaker screens also impact their pricing structure. Screens endorsed with international quality standards or specific industry certifications may have elevated prices. These certifications serve as a testament to their quality, reliability, and compliance with industry safety and performance standards, thereby building trust and credibility among users. Customer reviews and experiences provide empirical insights into the screen’s performance and value proposition. Exploring user experiences can offer practical understanding regarding the longevity, efficiency, and cost-benefit of different shaker screens, assisting in identifying the best value for money in practical scenarios. Users sharing their firsthand experiences often highlight long-term cost savings achieved through investing in technologically superior screens. In conclusion, the price of shale shaker screens is a composite of multiple interdependent factors, each contributing to its final cost. While striking a balance between cost and quality can be challenging, understanding these elements can facilitate informed purchasing decisions that align with both budgetary and operational necessities. Prioritizing quality, technological advancements, and reputable manufacturers ensures the selection of screens that not only meet immediate financial criteria but also provide long-term operational benefits. Engaging with established brands, staying informed about technological advancements, and considering the total cost of ownership are strategies that underscore expert purchasing in the realm of shale shaker screens.

Share

Latest news

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025