- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Factory for Manufacturing High-Quality Shale Shaker Screens and Accessories

Understanding Shale Shaker Screen Factories and Their Importance in the Oil and Gas Industry

Shale shakers are pivotal pieces of equipment used in the drilling industry, specifically in oil and gas exploration. They are designed to separate drilled cuttings from the drilling fluid, ensuring continuous operation and enhancing the efficiency of the drilling process. The core component of a shale shaker is its screen, which plays a crucial role in this separation process. With the increasing demand for oil and gas, the need for high-quality shale shaker screen factories has become more significant than ever.

The Role of Shale Shaker Screens

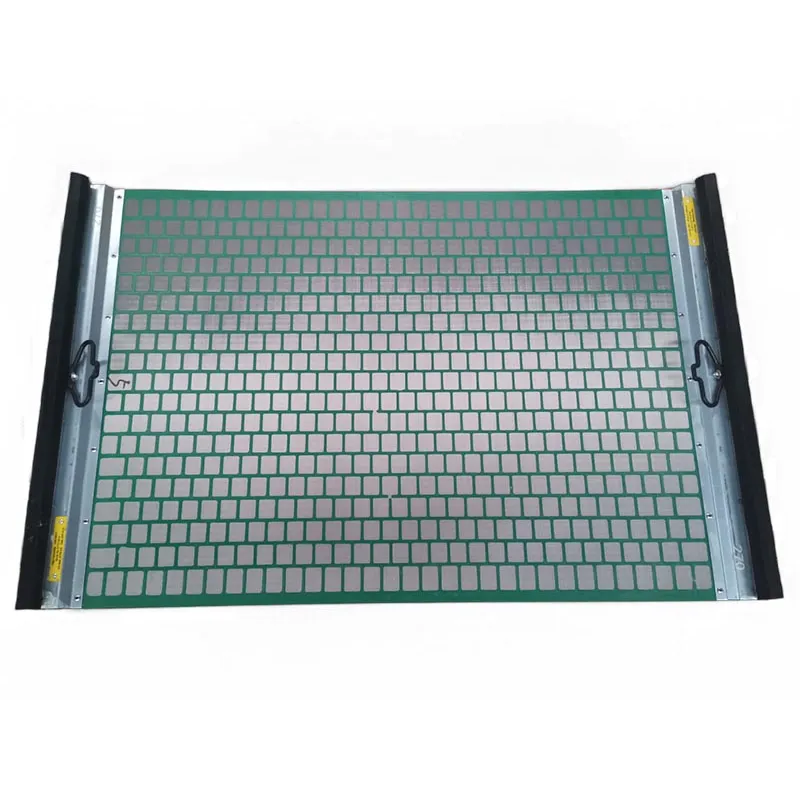

Shale shaker screens are typically made from a combination of mesh materials and are engineered to withstand the harsh conditions of drilling operations. Their primary function is to filter out solid particles from the drilling mud, allowing clean fluid to return down the hole. This not only helps maintain the viscosity and density of the drilling mud but also prevents costly blockages that could lead to operational downtimes.

The performance of a shale shaker screen directly affects the overall efficiency of the drilling operation. High-quality screens can help in reducing the volume of waste generated, improve fluid recovery, and minimize the environmental impact of drilling activities. As such, the manufacturing process of these screens demands precision and adherence to industry standards.

The Manufacturing Process

The production of shale shaker screens involves several key stages. First, raw materials such as stainless steel wire, polyurethane, and various composite materials are sourced. The choice of materials is crucial as they must be durable enough to handle abrasive drilling solids and chemical exposure.

Following material selection, the fabrication of the screen begins. This includes processes like weaving the wire to form a mesh, framing the screens for structural integrity, and applying coatings that enhance durability. Advanced technologies, such as CNC machines and automated weaving techniques, are often employed to ensure consistent quality and efficiency in production.

Quality control is a fundamental aspect of the manufacturing process. Each screen is tested for its flexibility, tensile strength, and filtration capability. These tests not only ensure that the screens meet the industry's rigorous standards but also provide assurance to customers regarding the product's reliability during operations.

shale shaker screen factory

Innovations in Shale Shaker Screen Technology

As the oil and gas industry continues to evolve, so does the technology behind shale shaker screens. Recent innovations focus on enhancing the durability and efficiency of these screens. Manufacturers are exploring new materials, such as high-strength composites, which offer superior performance characteristics while being lighter than traditional materials.

Another area of innovation is the design of screen mesh patterns. Advanced mesh configurations can improve the separation of drilling solids and increase the longevity of the screens, reducing the need for frequent replacements. Furthermore, manufacturers are leveraging data analytics and machine learning to predict screen performance based on specific drilling conditions, allowing for more tailored solutions.

Environmental Considerations

In today's environmentally conscious landscape, shale shaker screen factories are increasingly prioritizing sustainability. The oil and gas industry faces significant pressure to minimize its environmental impact. As a response, screen manufacturers are developing eco-friendly screens made from recyclable materials and improving their processes to reduce waste and energy consumption.

Conclusion

Shale shaker screens are essential for achieving operational efficiency in the oil and gas drilling industry. As the demand for oil and gas continues to grow, the significance of shale shaker screen factories increases. By adopting innovative manufacturing techniques, investing in quality control, and focusing on sustainability, these factories are not only enhancing their product offerings but also contributing to a more responsible industry.

The future of shale shaker screen technology looks promising, with advancements poised to improve the effectiveness of drilling operations while adhering to environmental standards. As the industry progresses, the vital role of shale shaker screen factories will continue to be a cornerstone in the pursuit of safe and efficient energy extraction.

-

Upgrade Your Industrial Operations with Durable Steel GratingNewsJul.21,2025

-

Transform Your Flooring Solutions with Quality Floor GratingNewsJul.21,2025

-

Top-Quality Shale Shaker Screens for Your Drilling NeedsNewsJul.21,2025

-

High-Quality Steel Grating for All Your Industrial NeedsNewsJul.21,2025

-

Explore the Durability and Versatility of Galvanized Steel GratingNewsJul.21,2025

-

Ensure Maximum Safety with Premium Safety NetsNewsJul.21,2025