- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Shale Shaker Screen - High-Efficiency Solid-Liquid Separation Solution | Anping County Hangshun Wire Mesh Manufacture Co., Ltd

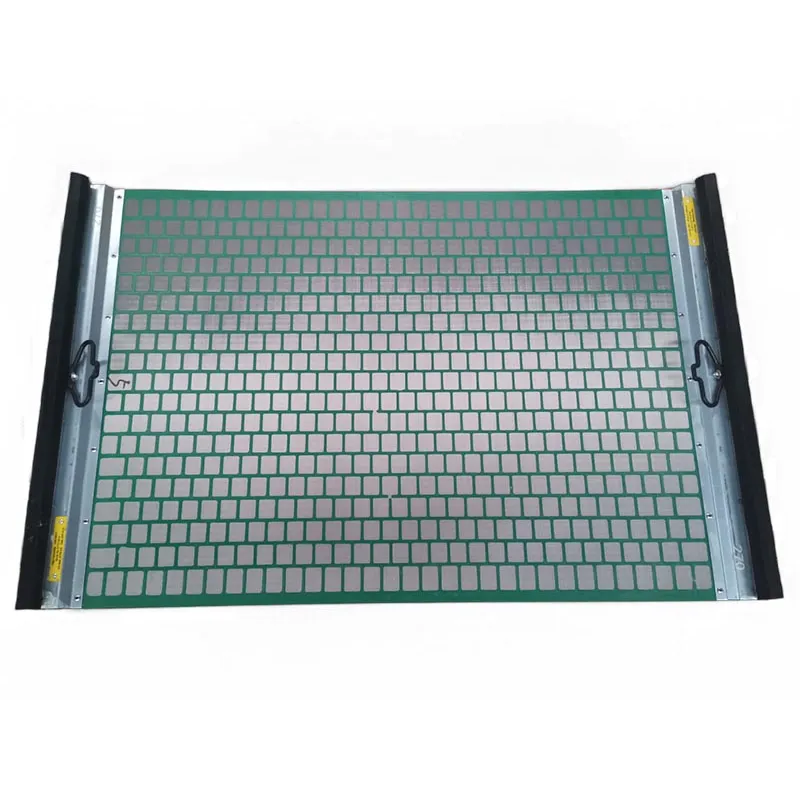

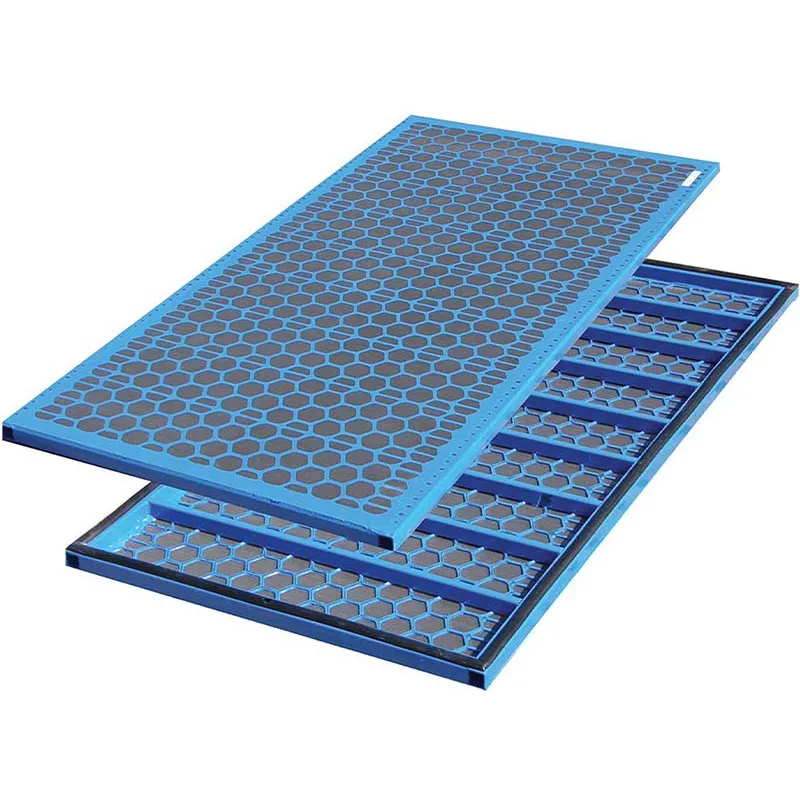

Shale Shaker Screen - Advanced Solid-Liquid Separation Equipment for Oil and Gas Industry

As a leading manufacturer in the petroleum industry, Anping County Hangshun Wire Mesh Manufacture Co., Ltd specializes in providing high-performance Shale Shaker Screen solutions. Our products are designed to meet the demanding requirements of drilling operations, offering efficient solid-liquid separation while ensuring long-term durability and cost-effectiveness.

Product Overview: Shale Shaker Screen

The Shale Shaker Screen is a critical component in the drilling fluid recycling system, designed to separate solid particles from drilling mud. Our screens are manufactured with advanced technology and high-quality materials, ensuring optimal performance in harsh environments. Key features include:

- High-Temperature Resistance: Made from durable stainless steel or polyurethane materials

- Customizable Mesh Sizes: Available in various aperture sizes (0.5mm-5mm)

- Anti-Corrosion Coating: Enhanced protection against chemical erosion

- High Load Capacity: Supports heavy drilling operations without deformation

Technical Specifications

| Parameter | Specification |

|---|---|

| Material | 304/316 stainless steel, polyurethane |

| Mesh Size | 0.5-5mm (customizable) |

| Screen Area | 1.5-6m² |

| Max Load Capacity | 2000kg/m² |

| Operating Temperature | -20°C to 80°C |

Key Applications

Our Shale Shaker Screen is widely used in:

- Oil and gas drilling operations

- Drilling fluid recycling systems

- Wastewater treatment plants

- Mineral processing industries

- Construction site mud management

Market Demand Analysis

With the global energy demand increasing, the oil and gas industry requires more efficient solid-liquid separation solutions. Traditional methods often face challenges such as:

- Low separation efficiency in high-solid-content environments

- Short lifespan of conventional screens

- High maintenance costs

- Environmental pollution risks

Our Shale Shaker Screen addresses these issues through:

- Advanced mesh design for optimal particle separation

- Durable materials that resist wear and tear

- Energy-efficient operation reducing overall costs

- Eco-friendly materials that minimize environmental impact

Company Strength and Technical Advantages

Anping County Hangshun Wire Mesh Manufacture Co., Ltd has been a trusted supplier in the petroleum industry for over 15 years. Our key strengths include:

- Professional R&D Team: 20+ engineers specializing in screen technology

- Advanced Manufacturing Equipment: State-of-the-art production lines for precision manufacturing

- Quality Control System: ISO 9001 certified with rigorous testing procedures

- Customized Solutions: Tailored screen designs to meet specific customer requirements

Product Performance and Customer Testimonials

Our Shale Shaker Screen has been successfully implemented in numerous projects, delivering measurable benefits:

- Increased separation efficiency by 30-50%

- Reduced maintenance frequency by 60%

- Extended screen lifespan up to 3 times

Customer feedback:

"The Shale Shaker Screens provided by Hangshun have significantly improved our drilling operations. The quality and performance exceed our expectations." - Customer A, XYZ Drilling Company

Usage Guide and Customization Options

Our Shale Shaker Screen can be customized to suit different drilling conditions:

- Material Selection: Choose between stainless steel (for high-temperature environments) or polyurethane (for abrasive materials)

- Mesh Configuration: Select from standard sizes or request custom mesh patterns

- Screen Dimensions: Available in multiple sizes to fit various shaker models

- Surface Treatment: Options include anti-corrosion coatings and wear-resistant layers

Safety and Environmental Compliance

All our Shale Shaker Screen products meet international safety standards, including:

- CE certification

- RoHS compliance

- ISO 14001 environmental management system

- OSHA safety regulations

Packaging and Shipping

We offer professional packaging solutions to ensure safe delivery:

- Custom wooden crates for large orders

- Moisture-proof packaging for sensitive materials

- International shipping options

- Real-time tracking system

Customer Support and After-sales Service

We provide comprehensive support to ensure your satisfaction:

- Technical Consultation: 24/7 support from experienced engineers

- On-site Installation: Professional team for equipment setup

- Warranty Service: 12-month warranty on all products

- Product Customization: Tailored solutions for unique requirements

Contact Us

For more information about our Shale Shaker Screen products, please contact us through:

- Phone: +86-312-5555555

- Email: sales@hfpetromesh.com

- Website: www.hfpetromesh.com

- Product Page: Shale Shaker Screen Details

FAQ

Q1: What are the main advantages of your Shale Shaker Screen?

A: Our screens offer high efficiency, long service life, and customizable options to meet various drilling conditions.

Q2: Can you provide samples for testing?

A: Yes, we can provide free samples for quality verification.

Q3: What is the delivery time?

A: Typically 15-30 days after order confirmation, depending on the quantity.

Q4: Do you have international shipping experience?

A: Yes, we have successfully exported to over 30 countries worldwide.

Conclusion

Invest in high-quality Shale Shaker Screen from Anping County Hangshun Wire Mesh Manufacture Co., Ltd to enhance your drilling operations. Our products combine advanced technology with practical applications to deliver optimal performance and cost savings.

-

Upgrade Your Industrial Operations with Durable Steel GratingNewsJul.21,2025

-

Transform Your Flooring Solutions with Quality Floor GratingNewsJul.21,2025

-

Top-Quality Shale Shaker Screens for Your Drilling NeedsNewsJul.21,2025

-

High-Quality Steel Grating for All Your Industrial NeedsNewsJul.21,2025

-

Explore the Durability and Versatility of Galvanized Steel GratingNewsJul.21,2025

-

Ensure Maximum Safety with Premium Safety NetsNewsJul.21,2025