- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

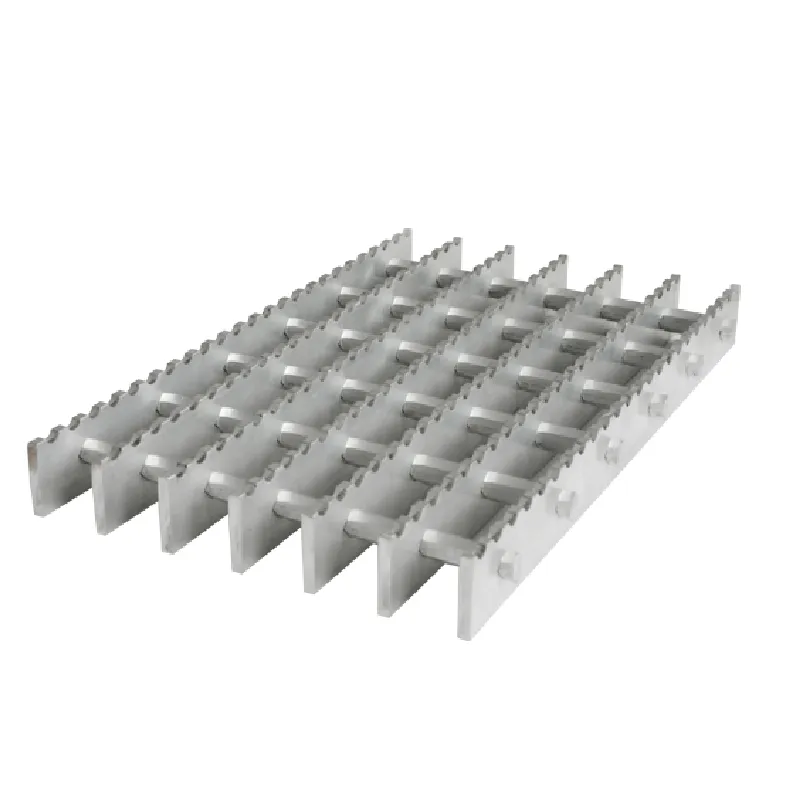

Galvanized Grating Steps for Safe and Durable Walkways in Various Applications

Galvanized Grating Steps A Comprehensive Look

Galvanized grating steps have become an integral part of many industrial and commercial settings. Their combination of strength, durability, and corrosion resistance makes them a preferred choice for various applications. In this article, we will explore what galvanized grating steps are, their benefits, uses, and maintenance, providing a comprehensive guide for potential users.

What are Galvanized Grating Steps?

Galvanized grating steps are typically made from steel that has been coated with a layer of zinc to enhance its resistance against corrosion. The galvanization process involves immersing steel in molten zinc, which forms a protective layer that prevents rust and decay. This makes galvanized grating steps especially suitable for environments exposed to moisture, chemicals, or extreme weather conditions.

These steps are constructed from grating, which is a structured framework of intersecting metal bars or rods. The design allows for excellent drainage and airflow while providing a stable walking surface. Galvanized grating steps can be manufactured in different sizes and configurations, catering to varying aesthetic and functional requirements.

Benefits of Galvanized Grating Steps

1. Corrosion Resistance One of the primary advantages of galvanized grating steps is their resistance to rust and corrosion. The zinc coating acts as a barrier, protecting the underlying steel from environmental factors like humidity and chemicals.

2. Durability Galvanized grating steps are exceptionally durable. They can withstand heavy loads, impacts, and wear, making them ideal for high-traffic areas. This longevity ultimately leads to reduced maintenance costs over time.

3. Safety The open design of grating steps allows water, oil, and other liquids to drain away, reducing the risk of slips and falls. Additionally, they can be equipped with non-slip surfaces to further enhance safety.

4. Ease of Installation Galvanized grating steps are relatively easy to install and can be customized to fit specific requirements. They are lightweight compared to solid metal alternatives, which simplifies handling and installation.

5. Aesthetic Appeal With a variety of finishes and designs available, galvanized grating steps can complement the aesthetics of both industrial and commercial spaces.

Applications of Galvanized Grating Steps

galvanized grating steps

Galvanized grating steps are utilized in a wide range of applications. Common uses include

- Industrial Facilities They are often found in factories, warehouses, and manufacturing plants, providing safe access to elevated areas and machinery. - Commercial Spaces Retail environments and shopping centers use grating steps to create attractive and functional pathways or staircases.

- Outdoor Settings Their resistance to environmental factors makes galvanized grating steps ideal for outdoor applications, such as at parks, public facilities, and recreation areas.

- Marine Applications Due to their corrosion resistance, these steps are frequently used in marinas and shipyards, providing safe access to boats and docks.

Maintenance of Galvanized Grating Steps

While galvanized grating steps are low maintenance, a few simple practices can help maximize their lifespan

1. Regular Inspections Periodically check for any signs of damage or wear, including loose grates or corrosion spots. Early detection can prevent more significant issues.

2. Cleaning Depending on the environment, it may be necessary to periodically clean the steps to remove debris, dirt, or chemical residues. A simple wash with water and mild detergent is often sufficient.

3. Repairs If any sections are damaged, it's essential to repair or replace them promptly to maintain safety and functionality.

4. Re-coating Over time, the zinc coating may wear away, particularly in high-wear areas. Consider re-coating the steps to restore their protective properties.

Conclusion

Galvanized grating steps offer a practical solution for safety and accessibility in various environments. Their robust construction, corrosion resistance, and ease of maintenance make them an excellent investment for industrial and commercial applications alike. Whether used in factories, outdoor recreational areas, or retail spaces, these steps provide a safe and durable option that meets the demands of modern usage. By understanding their benefits and applications, potential users can make informed decisions that enhance both the functionality and safety of their environments.

-

Upgrade Your Industrial Operations with Durable Steel GratingNewsJul.21,2025

-

Transform Your Flooring Solutions with Quality Floor GratingNewsJul.21,2025

-

Top-Quality Shale Shaker Screens for Your Drilling NeedsNewsJul.21,2025

-

High-Quality Steel Grating for All Your Industrial NeedsNewsJul.21,2025

-

Explore the Durability and Versatility of Galvanized Steel GratingNewsJul.21,2025

-

Ensure Maximum Safety with Premium Safety NetsNewsJul.21,2025