- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ఫిబ్ర . 14, 2025 22:21

Back to list

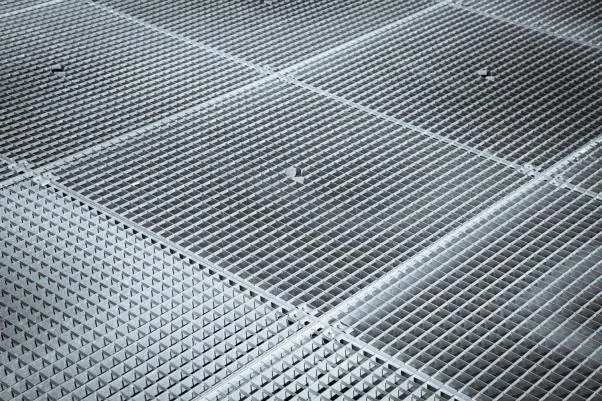

serrated metal grating

Serrated metal grating is an industrial staple renowned for its strength, durability, and slip-resistant capabilities, expertly catered to broad applications from walkways to complex industrial platforms. Its significant attributes are particularly impactful in ensuring safety and longevity in settings that require robust physical integrity under challenging conditions.

In terms of trustworthiness, the resale and repeated specification of serrated metal grating in new project plans speak volumes. Reputable manufacturers provide detailed test reports and load tables, ensuring that engineers and project managers can trust the grating for its specified application. Proactive consultation with manufacturers allows for customization, ensuring the grating not only meets immediate project needs but also considers future operational scalability. Case studies highlight projects where serrated metal grating reduced incident rates post-installation, contributing to workplace safety predominantly in environments where foot traffic is constant and the exposure to potentially hazardous substances is high. This empirical evidence supports the growing inclination towards integrating serrated metal grating in new builds and retrofitting projects, driven by a need to reinforce safety protocols. With an emphasis on professional expertise and integration of practical engineering principles, serrated metal grating is not just a product but a crucial component in ensuring the safety and operational efficiency of industrial environments. Its practical application, coupled with authoritative standards and trustworthiness from industry feedback, consolidates its stance as an essential asset in industrial construction and maintenance projects. Each installation serves as a testament to its necessity and versatility, proving its worth across varying scales and sectors.

In terms of trustworthiness, the resale and repeated specification of serrated metal grating in new project plans speak volumes. Reputable manufacturers provide detailed test reports and load tables, ensuring that engineers and project managers can trust the grating for its specified application. Proactive consultation with manufacturers allows for customization, ensuring the grating not only meets immediate project needs but also considers future operational scalability. Case studies highlight projects where serrated metal grating reduced incident rates post-installation, contributing to workplace safety predominantly in environments where foot traffic is constant and the exposure to potentially hazardous substances is high. This empirical evidence supports the growing inclination towards integrating serrated metal grating in new builds and retrofitting projects, driven by a need to reinforce safety protocols. With an emphasis on professional expertise and integration of practical engineering principles, serrated metal grating is not just a product but a crucial component in ensuring the safety and operational efficiency of industrial environments. Its practical application, coupled with authoritative standards and trustworthiness from industry feedback, consolidates its stance as an essential asset in industrial construction and maintenance projects. Each installation serves as a testament to its necessity and versatility, proving its worth across varying scales and sectors.

Share

Prev:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025