- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

జన . 21, 2025 02:05

Back to list

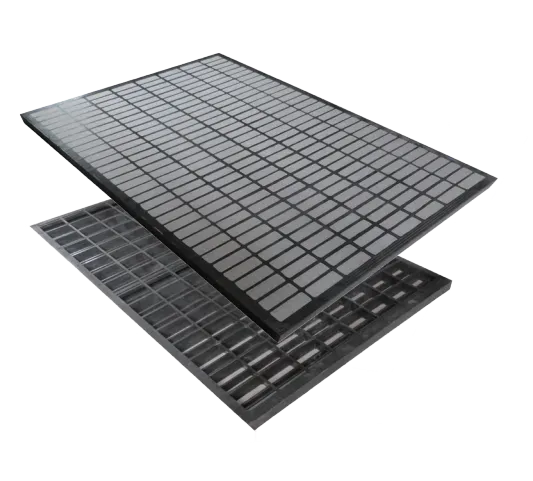

metal bar grating

Metal bar grating has emerged as a pivotal component across various industries, offering a blend of functionality, safety, and durability. With the ever-evolving demands for efficient and innovative infrastructure solutions, metal bar grating stands out due to its versatile applications and robust characteristics.

Trustworthiness in the application of metal bar grating extends beyond production and into installation and maintenance. Best practices in installation ensure that gratings are securely fixed and aligned to fulfill their purpose effectively. Moreover, regular maintenance inspections are advised to assess wear and address potential issues, thereby extending the lifespan of the grating system. In addressing specific industrial needs, custom solutions are becoming increasingly popular. Tailored designs and sizes meet project-specific requirements, showcasing the adaptability of metal bar grating to various spatial configurations and load conditions. The customization extends to surface treatments, where options like galvanized or powder-coated finishes enhance durability and aesthetic appeal. As sustainability becomes a significant focus for industries worldwide, metal bar grating also contributes positively due to its recyclability. The materials used can be recycled without degrading in quality, aligning with green building practices and reducing environmental impact. This aspect enhances the appeal of metal bar grating in sectors aiming for eco-friendly certifications. Overall, the seamless integration of experience, expertise, authoritativeness, and trustworthiness in the manufacture and application of metal bar grating positions it as an indispensable resource in modern architecture and industry. Its incredible versatility, coupled with proven performance and adherence to international standards, grants it a distinguished status in infrastructure development, setting a benchmark for quality and reliability in various applications. As industries continue to evolve, the role of metal bar grating is anticipated to expand, driven by innovation and a commitment to sustainability.

Trustworthiness in the application of metal bar grating extends beyond production and into installation and maintenance. Best practices in installation ensure that gratings are securely fixed and aligned to fulfill their purpose effectively. Moreover, regular maintenance inspections are advised to assess wear and address potential issues, thereby extending the lifespan of the grating system. In addressing specific industrial needs, custom solutions are becoming increasingly popular. Tailored designs and sizes meet project-specific requirements, showcasing the adaptability of metal bar grating to various spatial configurations and load conditions. The customization extends to surface treatments, where options like galvanized or powder-coated finishes enhance durability and aesthetic appeal. As sustainability becomes a significant focus for industries worldwide, metal bar grating also contributes positively due to its recyclability. The materials used can be recycled without degrading in quality, aligning with green building practices and reducing environmental impact. This aspect enhances the appeal of metal bar grating in sectors aiming for eco-friendly certifications. Overall, the seamless integration of experience, expertise, authoritativeness, and trustworthiness in the manufacture and application of metal bar grating positions it as an indispensable resource in modern architecture and industry. Its incredible versatility, coupled with proven performance and adherence to international standards, grants it a distinguished status in infrastructure development, setting a benchmark for quality and reliability in various applications. As industries continue to evolve, the role of metal bar grating is anticipated to expand, driven by innovation and a commitment to sustainability.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025