- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

பிப் . 18, 2025 01:49

Back to list

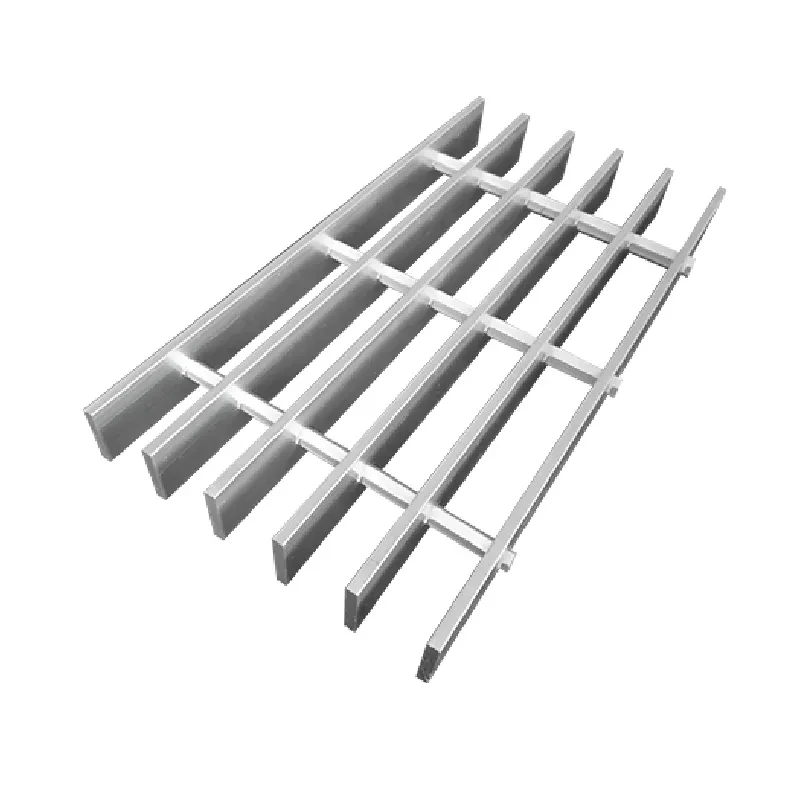

Steel Grating

Steel grating is a versatile building and manufacturing material used in a variety of applications across several industries. It is designed to provide high levels of strength, durability, and safety. Steel gratings are typically made from flat bars of steel that are cross-welded to form a grid-like structure, making them suitable for numerous applications that require both strength and surface drainage.

Environmental sustainability is also a growing concern in industrial design and construction. Steel grating addresses this issue as it is 100% recyclable. Once the grating has reached the end of its life cycle, it can be reprocessed and reused, significantly reducing the environmental impact associated with disposal. This feature aligns with today’s increasing emphasis on sustainable building practices and resource conservation. When delving into the expertise of steel grating manufacturing, it is essential to consider the role of customization and specification standards. Industry requirements often mandate specific load-bearing capacities, surface treatments, and dimensions. Reputable manufacturers adhere to international standards such as the American National Standards Institute (ANSI) or the American Society for Testing and Materials (ASTM), assuring end-users of the quality and consistency of their steel grating products. Reputable sources in the field of steel manufacturing and construction often conduct periodic reviews and testing to ensure adherence to high standards. Authoritative publications and expert forums frequently provide insights into the latest innovations, technologies, and best practices surrounding steel grating. This ensures that engineers and architects are equipped with current knowledge and cutting-edge solutions for their projects. Building trust in the steel grating industry significantly relies on transparent service and product offerings. Clients benefit from detailed specifications, clear communication regarding load capacities, and available design options. Customer reviews and case studies provide invaluable feedback and validation from real-world applications, further enhancing the trustworthiness of the product and its suppliers. In conclusion, steel grating has established itself as a reliable and versatile solution across numerous industries. Its combination of strength, safety, adaptability, and sustainability makes it a preferred material for various applications. As technology and environmental considerations continue to advance, steel grating remains at the forefront of material choices for safe, efficient, and eco-friendly industrial design. As the industry advances, continuous innovation and adherence to quality standards will keep steel grating as a cornerstone of structural design and safety.

Environmental sustainability is also a growing concern in industrial design and construction. Steel grating addresses this issue as it is 100% recyclable. Once the grating has reached the end of its life cycle, it can be reprocessed and reused, significantly reducing the environmental impact associated with disposal. This feature aligns with today’s increasing emphasis on sustainable building practices and resource conservation. When delving into the expertise of steel grating manufacturing, it is essential to consider the role of customization and specification standards. Industry requirements often mandate specific load-bearing capacities, surface treatments, and dimensions. Reputable manufacturers adhere to international standards such as the American National Standards Institute (ANSI) or the American Society for Testing and Materials (ASTM), assuring end-users of the quality and consistency of their steel grating products. Reputable sources in the field of steel manufacturing and construction often conduct periodic reviews and testing to ensure adherence to high standards. Authoritative publications and expert forums frequently provide insights into the latest innovations, technologies, and best practices surrounding steel grating. This ensures that engineers and architects are equipped with current knowledge and cutting-edge solutions for their projects. Building trust in the steel grating industry significantly relies on transparent service and product offerings. Clients benefit from detailed specifications, clear communication regarding load capacities, and available design options. Customer reviews and case studies provide invaluable feedback and validation from real-world applications, further enhancing the trustworthiness of the product and its suppliers. In conclusion, steel grating has established itself as a reliable and versatile solution across numerous industries. Its combination of strength, safety, adaptability, and sustainability makes it a preferred material for various applications. As technology and environmental considerations continue to advance, steel grating remains at the forefront of material choices for safe, efficient, and eco-friendly industrial design. As the industry advances, continuous innovation and adherence to quality standards will keep steel grating as a cornerstone of structural design and safety.

Share

Prev:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025