- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

பிப் . 18, 2025 00:58

Back to list

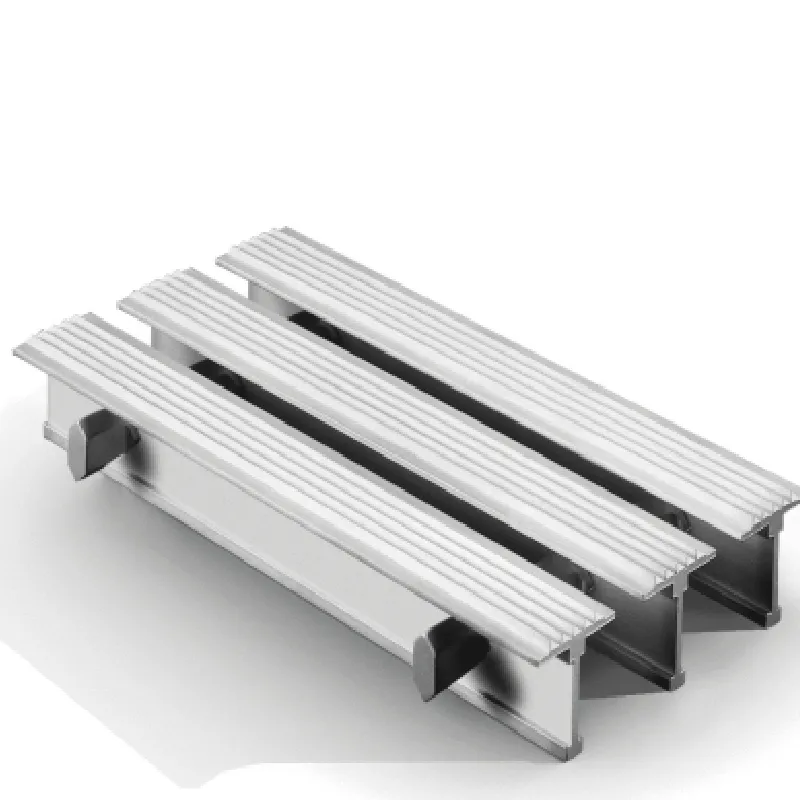

Swage-Locked Steel Grating

Purchasing steel grating is a crucial decision for industries ranging from construction to manufacturing. Based on extensive experience and proven expertise, choosing the right type of steel grating can significantly enhance safety, functionality, and longevity in various applications.

In terms of design, grating layout plays a significant role in performance. Open mesh designs facilitate superior drainage and airflow, crucial in environments where water or debris management is essential. Conversely, close mesh designs provide better foot traffic safety while preventing objects from passing through, a consideration in high-footfall areas or where small tools and components are in use. The power of a well-chosen design underscores the need for detailed planning and consultation with professionals in engineering and architecture. Trustworthiness also extends into delivery and installation. Selecting a supplier with a track record of timely delivery and efficient installation processes can prevent costly delays. Reliable suppliers often provide comprehensive installation guides or services, ensuring that grating is fitted correctly to prevent future failures. Additionally, some offer maintenance programs that monitor performance and preemptively address wear and potential damage. The evolution of steel grating technologies has introduced innovations like anti-slip coatings and enhanced load-bearing capabilities, offering added safety and functionality. Embracing technological advancements can provide competitive advantages, such as reduced workplace accidents and extended product life. When evaluating suppliers, inquire about their latest innovations and how these could be adapted to meet project goals. In conclusion, purchasing steel grating is not merely a transaction but an investment in operational efficiency and safety. By leveraging experience, choosing the right material, engaging with authoritative suppliers, and prioritizing trust, clients can ensure that their steel grating solution is nothing short of optimal. Through strategic decision-making, businesses can maximize the utility of their investment, thereby securing a solid foundation for future growth and stability.

In terms of design, grating layout plays a significant role in performance. Open mesh designs facilitate superior drainage and airflow, crucial in environments where water or debris management is essential. Conversely, close mesh designs provide better foot traffic safety while preventing objects from passing through, a consideration in high-footfall areas or where small tools and components are in use. The power of a well-chosen design underscores the need for detailed planning and consultation with professionals in engineering and architecture. Trustworthiness also extends into delivery and installation. Selecting a supplier with a track record of timely delivery and efficient installation processes can prevent costly delays. Reliable suppliers often provide comprehensive installation guides or services, ensuring that grating is fitted correctly to prevent future failures. Additionally, some offer maintenance programs that monitor performance and preemptively address wear and potential damage. The evolution of steel grating technologies has introduced innovations like anti-slip coatings and enhanced load-bearing capabilities, offering added safety and functionality. Embracing technological advancements can provide competitive advantages, such as reduced workplace accidents and extended product life. When evaluating suppliers, inquire about their latest innovations and how these could be adapted to meet project goals. In conclusion, purchasing steel grating is not merely a transaction but an investment in operational efficiency and safety. By leveraging experience, choosing the right material, engaging with authoritative suppliers, and prioritizing trust, clients can ensure that their steel grating solution is nothing short of optimal. Through strategic decision-making, businesses can maximize the utility of their investment, thereby securing a solid foundation for future growth and stability.

Share

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025