- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Understanding the Benefits and Applications of Welded Bar Grating in Industrial Design and Construction

Understanding Welded Bar Grating Applications and Benefits

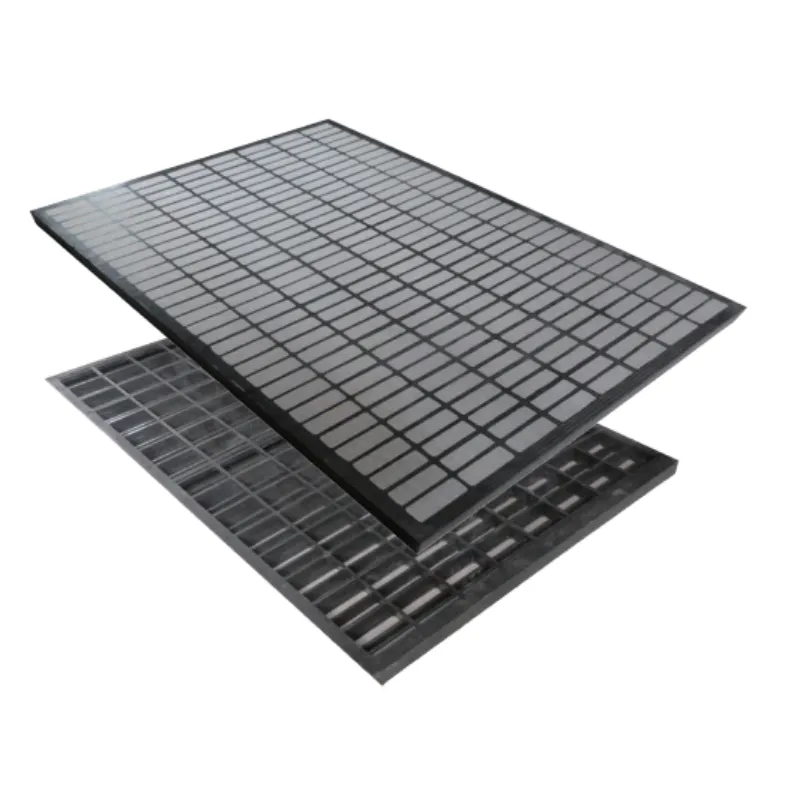

Welded bar grating is an essential component in various industries, providing strength, durability, and safety for flooring and walkway applications. Engineered by welding together bearing bars and cross bars, this type of grating is noted for its structural integrity, making it a popular choice for heavy-duty environments. From manufacturing plants to commercial buildings, welded bar grating plays a critical role in supporting loads while allowing for efficient drainage and air circulation.

Composition and Design

Welded bar grating is typically constructed from steel, stainless steel, or aluminum, and is designed in a range of styles and sizes to meet specific application needs. The primary components include bearing bars, which run the length of the grating, and cross bars, which run perpendicular to the bearing bars. This configuration creates a grid-like structure that is not only strong but also light, enabling easy handling and installation.

The spacing between the bars can be customized based on the application requirements. For instance, wider spacing can increase airflow and drainage, making the grating suitable for environments exposed to rain or spills, while closer spacing can provide added support in areas subjected to heavy foot traffic or machinery.

Applications

Welded bar grating is versatile and used across various sectors, including

1. Industrial In factories and plants, welded bar grating is commonly utilized for walkways, platforms, and stair treads. Its ability to withstand heavy loads makes it ideal for operating heavy machinery and equipment.

2. Commercial In commercial buildings, this type of grating is employed in roofs, mezzanines, and loading docks. Its aesthetic appeal and robust construction provide both safety and functionality.

3. Transportation Welded bar grating is also used in bridge decks, railway platforms, and other transportation infrastructures, where strength and durability are paramount.

welded bar grating

Advantages

The advantages of welded bar grating are manifold

- Strength and Durability The welding process creates a strong bond between bars, enhancing load capacity and longevity. This makes it suitable for high-impact and high-load environments.

- Corrosion Resistance When manufactured from stainless steel or coated with protective materials, welded bar grating can resist corrosion, making it ideal for outdoor or harsh environments.

- Safety The slip-resistant surface provides safety underfoot, reducing the likelihood of slips and falls, which is critical in industrial and commercial settings.

- Ease of Maintenance The open design of welded bar grating allows for easy cleaning and maintenance, ensuring that debris and contaminants can be quickly removed.

- Cost-effectiveness With its durability and minimal maintenance requirements, welded bar grating presents a long-term cost-effective solution for flooring and structural support.

Conclusion

In conclusion, welded bar grating is a robust and versatile solution that meets the needs of various industries. Its unique combination of strength, safety, and ease of maintenance makes it a top choice for flooring and structural applications. As industries continue to evolve, the demand for such durable materials is expected to grow, reinforcing the importance of welded bar grating in construction and infrastructure projects. Understanding its benefits and applications is pivotal for engineers and designers to make informed decisions in their projects.

-

The Versatility of Steel Walkway GratingNewsAug.07,2025

-

The Benefits of Galvanized Steel Grating for Your ProjectsNewsAug.07,2025

-

Shaker Screens: The Ultimate Solution for Your Drilling NeedsNewsAug.07,2025

-

Perimeter Safety Net: An Essential Solution for Helipad SafetyNewsAug.07,2025

-

Enhance Safety and Efficiency with Steel Walkway GratingNewsAug.07,2025

-

Discover Exceptional Steel Grating for SaleNewsAug.07,2025