- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Mechi . 06, 2025 11:44

Back to list

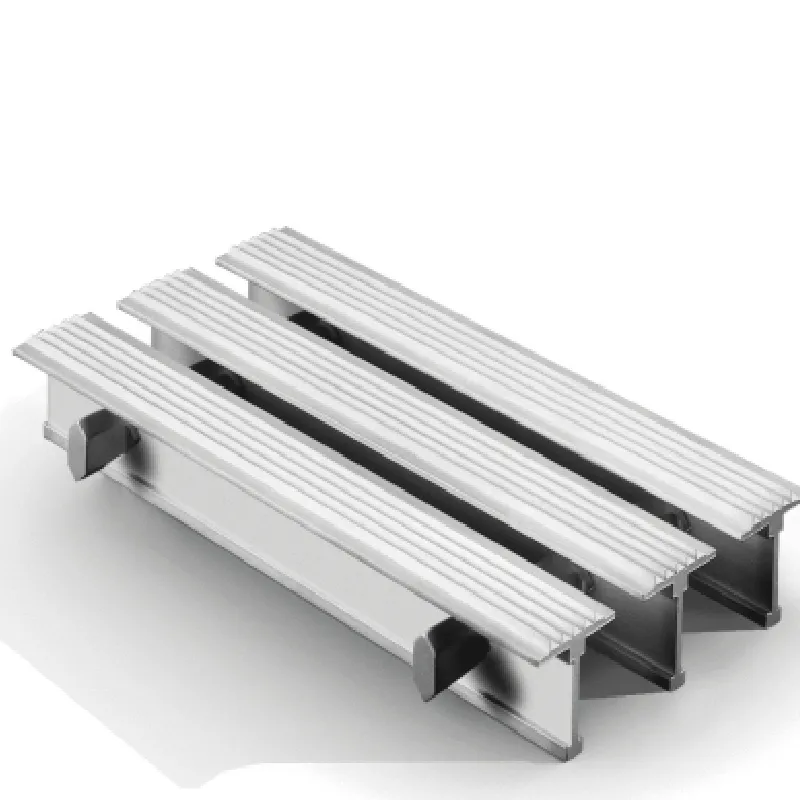

grating galvanised

When considering the myriad of materials available for construction and industrial applications, grating galvanised steel emerges as a standout option. Its benefits aren't merely theoretical; they have been proven in various demanding environments and applications, earning it an esteemed position in the industry. Through a deep dive into the properties and applications of galvanised grating, one can truly appreciate its value, further supporting the material's relevance in contemporary construction.

From the perspective of safety—paramount in any industrial or public domain—galvanised grating excels by providing slip resistance in wet or oily conditions. The open-grid design effectively drains water or any other liquid, minimizing the hazard risk. This safety feature is complemented by the innate strength of the material, able to bear substantial weight without bending or warping. Nevertheless, the environmental aspects of galvanised grating should also be considered. While some might argue the environmental footprint of steel production is considerable, galvanised steel's longevity and recyclability present counterpoints. The durability afforded by the zinc coating means that structures built today won’t need replacing for decades, reducing consumption and waste. Moreover, at the end of its lifecycle, galvanised steel is entirely recyclable, aligning with the current push towards sustainable construction practices. Industry experts, regulatory bodies, and manufacturers play a pivotal role in advancing and endorsing the use of galvanised grating. Their collective expertise ensures that the production processes, quality standards, and application guidelines for galvanised grating continue to evolve, reflecting advancements in technology and sustainability. By advocating for rigorous testing and certification, they affirm the material's capability to meet or even surpass industry standards, fostering trust among specifiers and end-users alike. In conclusion, grating galvanised steel embodies the intersection of performance, resilience, and adaptability. Its myriad benefits, from corrosion resistance and versatile applications to safety and recyclability, have earned it a respected place in modern construction and industrial projects. Its usage is not only driven by its superior properties but also by testimonials and endorsements from industry professionals and experts who have witnessed its benefits firsthand. Thus, those looking to build with a material that offers not just promise but proven efficacy, will find in galvanised grating an unparalleled ally.

From the perspective of safety—paramount in any industrial or public domain—galvanised grating excels by providing slip resistance in wet or oily conditions. The open-grid design effectively drains water or any other liquid, minimizing the hazard risk. This safety feature is complemented by the innate strength of the material, able to bear substantial weight without bending or warping. Nevertheless, the environmental aspects of galvanised grating should also be considered. While some might argue the environmental footprint of steel production is considerable, galvanised steel's longevity and recyclability present counterpoints. The durability afforded by the zinc coating means that structures built today won’t need replacing for decades, reducing consumption and waste. Moreover, at the end of its lifecycle, galvanised steel is entirely recyclable, aligning with the current push towards sustainable construction practices. Industry experts, regulatory bodies, and manufacturers play a pivotal role in advancing and endorsing the use of galvanised grating. Their collective expertise ensures that the production processes, quality standards, and application guidelines for galvanised grating continue to evolve, reflecting advancements in technology and sustainability. By advocating for rigorous testing and certification, they affirm the material's capability to meet or even surpass industry standards, fostering trust among specifiers and end-users alike. In conclusion, grating galvanised steel embodies the intersection of performance, resilience, and adaptability. Its myriad benefits, from corrosion resistance and versatile applications to safety and recyclability, have earned it a respected place in modern construction and industrial projects. Its usage is not only driven by its superior properties but also by testimonials and endorsements from industry professionals and experts who have witnessed its benefits firsthand. Thus, those looking to build with a material that offers not just promise but proven efficacy, will find in galvanised grating an unparalleled ally.

Share

Prev:

Next:

Latest news

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025